Method for efficiently removing slag splashing layer at joint of bottom and body of converter with movable bottom

A converter furnace bottom and joint technology, applied in the direction of manufacturing converters, etc., can solve the problems of ineffective separation of the furnace bottom and the furnace body, increasing the soaking time of the slag splashing layer, and incomplete removal of the slag splashing layer, etc., to avoid The effect of broken steel accident, high work efficiency and less time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

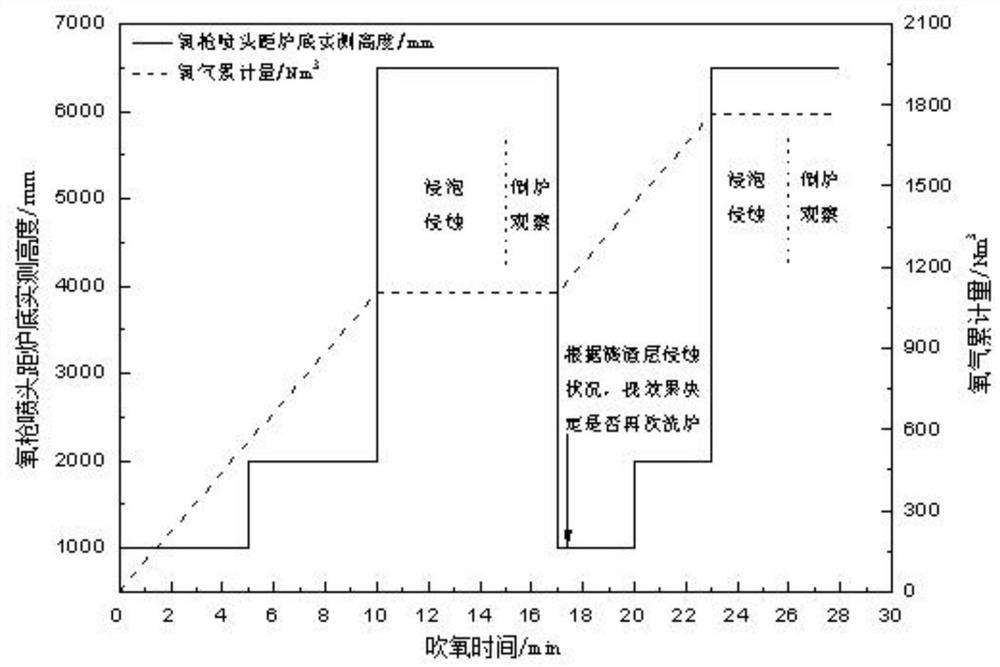

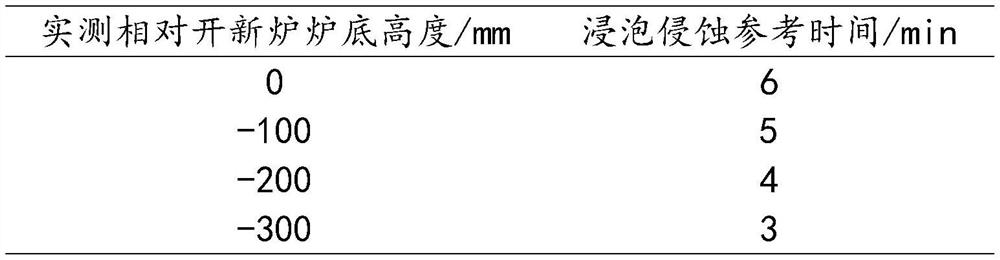

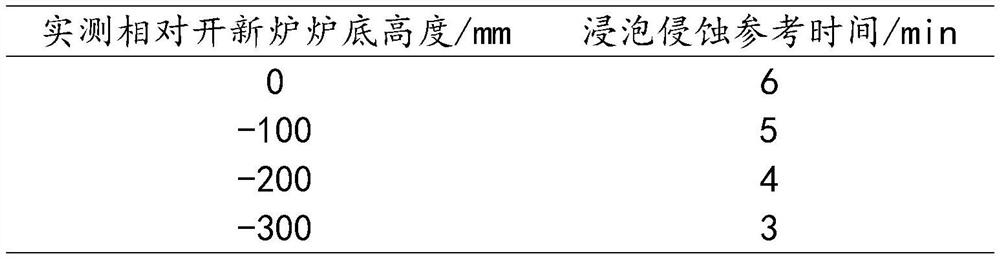

[0056] Furnace 203-10636 was scheduled to shut down, and the furnace was not repaired 25 hours before the shutdown. Before the shutdown, furnace 203-10635 was tapped, and the final slag in the furnace was cleaned, and a laser thickness gauge was used to measure the thickness of the lining working layer and the actual bottom of the furnace. Height, the measured weakest part of the slag line on the south side of the working layer of the converter is 112mm, and the height of the furnace bottom relative to the newly opened furnace is ±0mm. The amount is controlled at 25kg / t steel, and then the oxygen blowing operation is carried out. The oxygen blowing operation includes the following steps:

[0057] S1: After the slag dumping is completed, the converter is shaken to zero position;

[0058] S2: Oxygen blowing with the lower lance, set the oxygen pressure to 330kpa, the oxygen flow rate to 6600Nm3 / h, the oxygen supply intensity to 1.6Nm3 (min t), the oxygen lance position to 0mm, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com