High-frequency impulse airflow beam foreign matter removal system

A technology of high-frequency pulse and foreign matter, which is applied in the field of high-frequency pulse air beam foreign matter removal system, can solve the problems of large tobacco loss, affecting product quality, and inability to achieve precise control, and achieve the effect of accurate positioning and precise removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

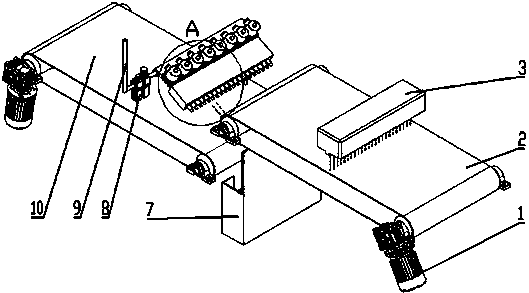

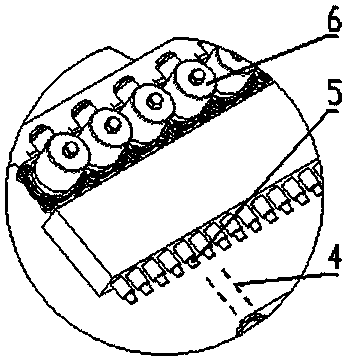

[0015] Such as figure 1 and 2 As shown, the present invention includes a first belt conveyor 10, a second belt conveyor 2, a speed sensor, a foreign matter detection device, a foreign matter rejecting device and a processing controller, the first belt conveyor 10 and the second The belt conveyor 2 is arranged end to end, and the second belt conveyor 2 is above the first belt conveyor 10; the foreign object detection device 3 is arranged above the second belt conveyor 2, and the foreign object removal device is arranged on At the gap between the first belt conveyor 10 and the second belt conveyor 2, the speed sensor is fixedly arranged on one side of the second belt conveyor 2 for real-time detection of the speed of the second belt conveyor 2 ; The speed sensor can measure the speed of the reducer 1 for conversion, and can also directly measure its linear speed.

[0016] The foreign matter removal device includes a high-frequency pulse air gun 5, a plurality of pulse control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com