Fermentation type compound feed for laying hens

A compound feed and fermented technology, applied in the field of laying hen feed, can solve the problems of limited enzymatic hydrolysis of raw material substrates, low utilization rate of corn by-products, lack of production performance of laying hens, etc., to enhance the immune function of intestinal mucosa, The effect of protecting intestinal health and reducing feeding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

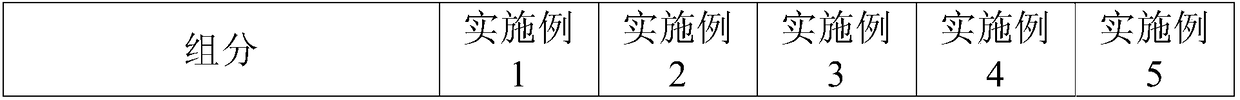

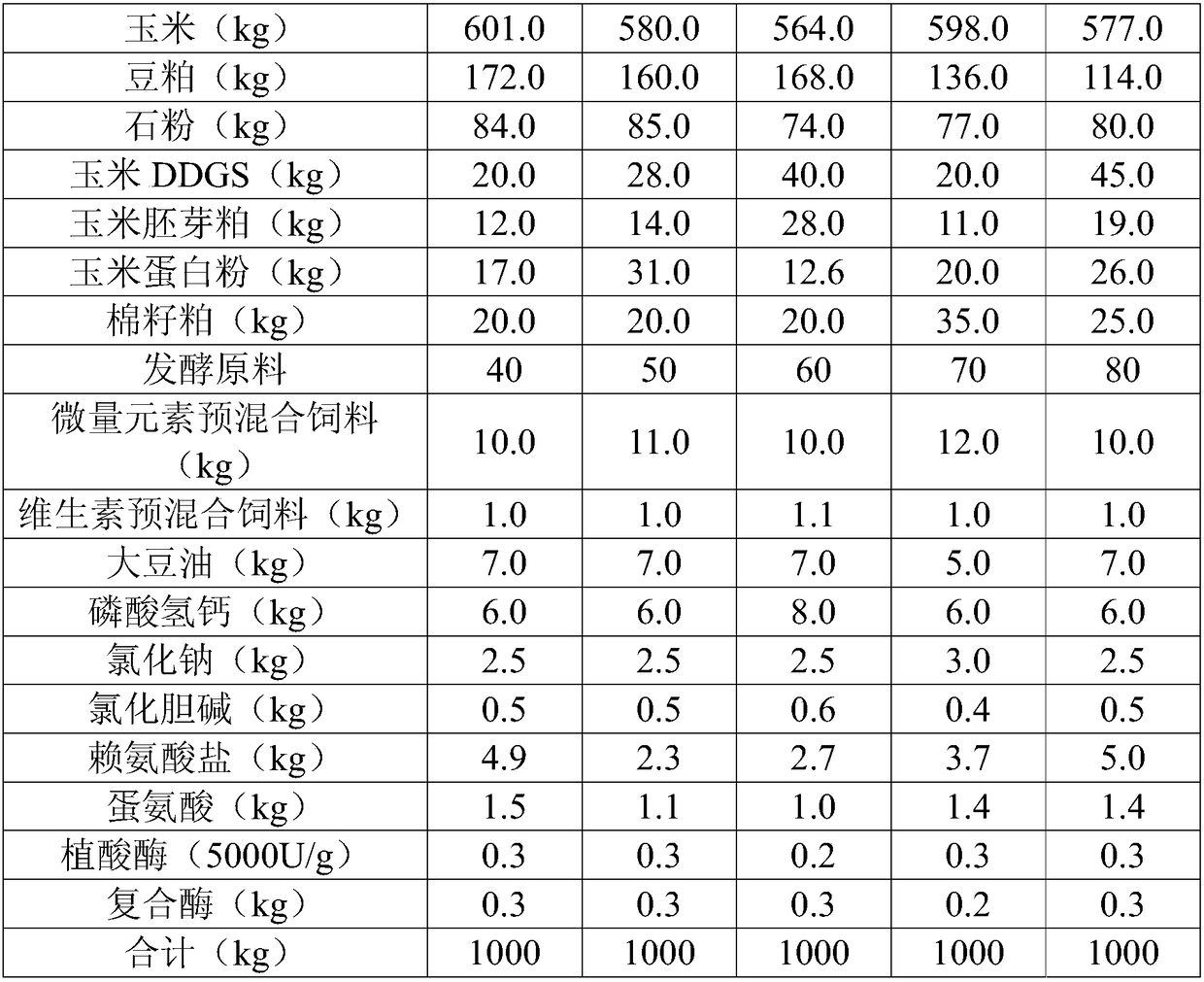

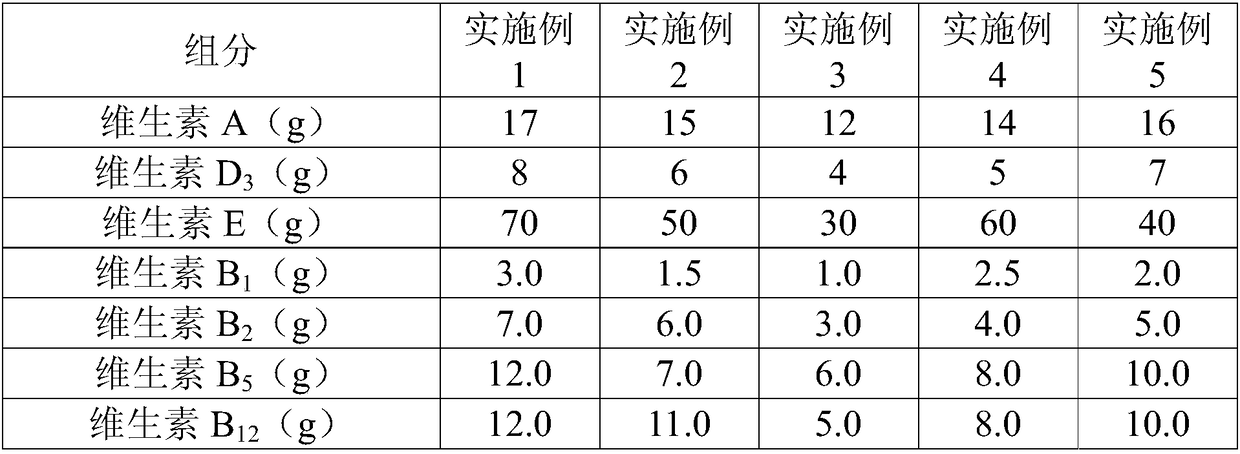

[0020] According to the proportions of each example in Table 1 to Table 4, firstly crush cotton meal, corn gluten powder, corn DDGS, and corn germ meal to a woven sieve with a particle size of <4.5mm, then add other components, mix them in a mixer and pack them That is, the finished product is a powder.

[0021] The fermentation raw materials are composed of corn, soybean meal, wheat bran, and fermentation liquid containing bacteria (the bacteria are purchased from the market and produced by Hubei Huada Ruier Technology Co., Ltd.). Grind 100 parts of dry matter (including 60 parts of corn, 20 parts of soybean meal, and 20 parts of wheat bran) with a pulverizer with a 2.0mm screen and mix them evenly. Ferment for one week to make fermented raw materials for later use. Every 100 parts by weight of the aqueous solution containing bacteria contains 2 parts of white sugar, 0.4 parts of bacteria and the rest of water. Each 1 gram of bacteria contains 3 to 8 billion CFU of Bacillus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com