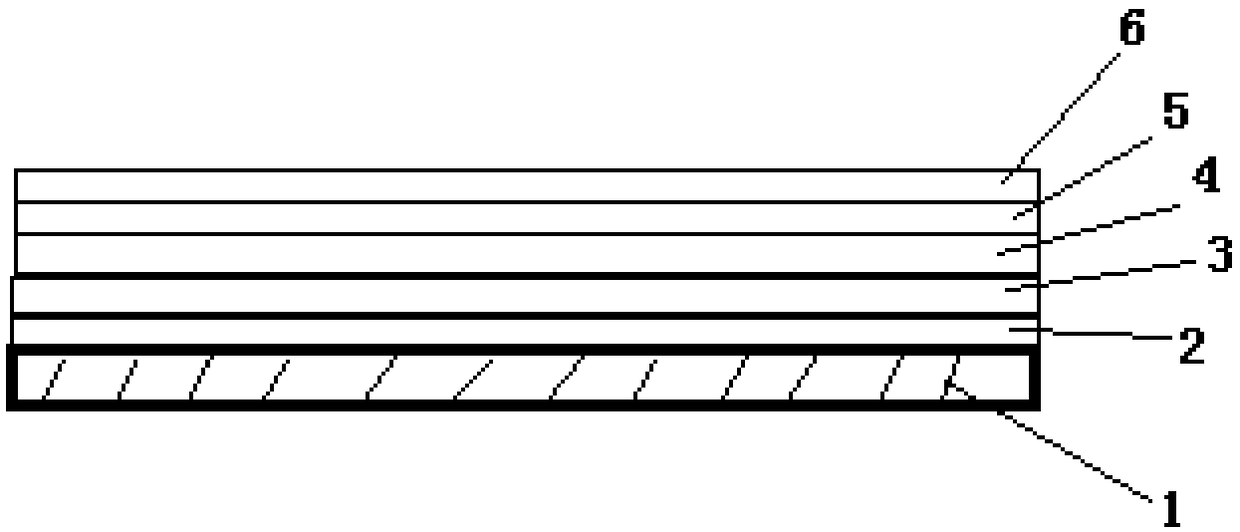

N-VO2/p-NiO-based heterogeneous structure and preparation method thereof

A heterogeneous structure, VO2 technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of complex drive circuits, low switching speed, and low service life, and achieve large film forming area and low resistivity. The effect of reducing and lowering the substrate temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1), the flexible stainless steel substrate was ultrasonically cleaned with ethanol and deionized water in sequence, the time of ultrasonic cleaning with ethanol was 5 minutes, the time of ultrasonic cleaning with deionized water was 5 minutes, blown dry with nitrogen gas, and sent to the magnetron sputtering reaction chamber. 1.0×10 -3 Under the condition of Pa vacuum, AZO transparent conductive film was deposited and prepared on its flexible stainless steel; the process parameter conditions were: argon and oxygen were used as the mixed gas reaction source, the flow ratio of argon and oxygen was 8:1, zinc oxide doped Doped aluminum is used as the target material, the purity of the reactive sputtering zinc oxide doped aluminum target material is 99.9%, the preparation temperature is 200° C., and the preparation time is 60 minutes to obtain a flexible stainless steel substrate / second AZO transparent conductive film.

[0035] 2), using a magnetron sputtering reaction chamb...

Embodiment 2

[0040] 1), the flexible stainless steel substrate was ultrasonically cleaned with ethanol and deionized water in sequence, the time of ultrasonic cleaning with ethanol was 5 minutes, the time of ultrasonic cleaning with deionized water was 5 minutes, blown dry with nitrogen gas, and sent to the magnetron sputtering reaction chamber. 1.0×10 -3 Under the condition of Pa vacuum, AZO transparent conductive film was deposited and prepared on the flexible stainless steel; the process parameter conditions were: argon and oxygen were used as the mixed gas reaction source, the flow ratio of argon and oxygen was 9:1, zinc oxide doped Doped aluminum is used as the target material, the purity of the reactive sputtering zinc oxide doped aluminum target material is 99.9%, the preparation temperature is 250° C., and the preparation time is 70 minutes to obtain a flexible stainless steel substrate / second AZO transparent conductive film.

[0041] 2), using a magnetron sputtering reaction chamb...

Embodiment 3

[0046] 1), the flexible stainless steel substrate is ultrasonically cleaned with ethanol and deionized water in sequence, the time of ultrasonic cleaning with ethanol is 5 minutes, the time of ultrasonic cleaning with deionized water is 5 minutes, blown dry with nitrogen gas, and sent to the magnetron sputtering reaction chamber. 1.0×10 -3 Under the condition of Pa vacuum, AZO transparent conductive film is deposited and prepared on the flexible stainless steel; the process parameter conditions are: argon and oxygen are used as the mixed gas reaction source, the flow ratio of argon and oxygen is 10:1, zinc oxide doped Doped aluminum is used as the target material, the purity of the reactive sputtering zinc oxide-doped aluminum target material is 99.9%, the preparation temperature is 300° C., and the preparation time is 80 minutes to obtain a flexible stainless steel substrate / second AZO transparent conductive film.

[0047] 2), using a magnetron sputtering reaction chamber to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com