A rectangular drilling stress monitoring device and monitoring method

A stress monitoring, rectangular technology, applied in the direction of force sensors, buildings, etc. in the holes of the stressed structure, can solve the problems of low drilling utilization rate, difficulty in determining the stress direction, and error in the stress measurement results, so as to improve the drilling efficiency. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

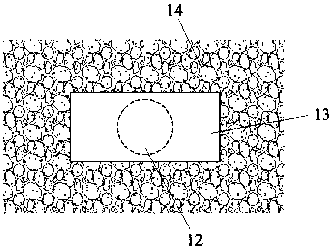

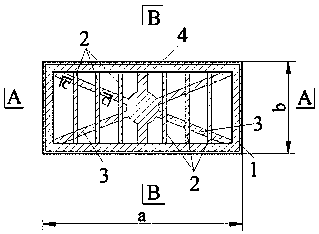

[0039] The device of the invention comprises a rectangular drill bit, a drill pipe and a rectangular borehole stress monitor.

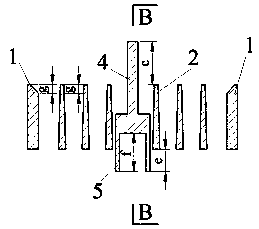

[0040] Such as figure 1 As shown, the rectangular drill bit includes an outer frame 1, and the outer frame is provided with a forward cutter 2 fixedly connected to the frame, an oblique cutter 3 and a center guide cutter 4, and the center guide cutter The middle part is provided with a connecting screw hole 5, and the connecting screw hole 5 is used for connecting with the drill rod 15, and the rectangular drill bit is pushed forward by the thrust of the drill rod. In this embodiment, the outer frame is provided with 6 forward cutters, 2 oblique cutters, 1 central guide cutter and 1 connecting screw hole. The 6 forward cutting knives are parallel to the two short sides of the outer frame and connected to the two long sides of the outer frame, and the forward cutting knives are parallel to each other.

[0041] Such as figure 2 As shown, the outer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com