Spunbond and preparation method thereof

A spunbonded fabric, longitudinal technology, applied in textiles and papermaking, heating/cooling fabrics, fabric surface trimming, etc., can solve problems such as large stretching deformation, and achieve stable structure, uniform longitudinal and transverse drafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this example, a method for preparing a spunbond fabric is provided. The preparation method of this example can prepare a high-strength and low-stretch spunbond fabric, which can be placed in furniture, sofas, seats, etc. . The preparation method of this embodiment can not only prepare spun-bonded fabrics, but also non-woven fabrics of other materials.

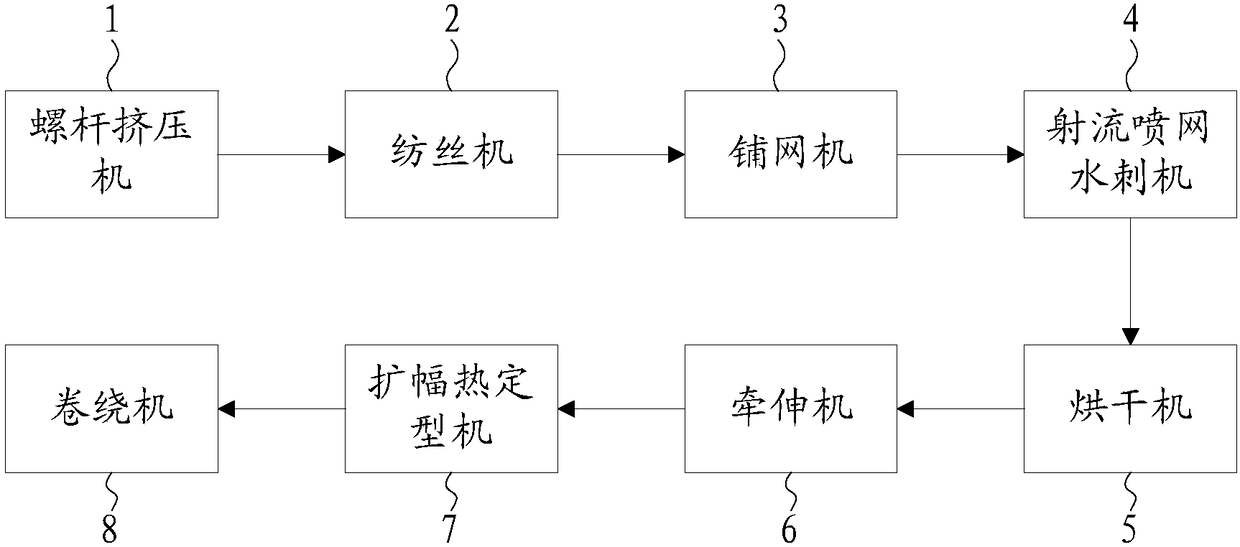

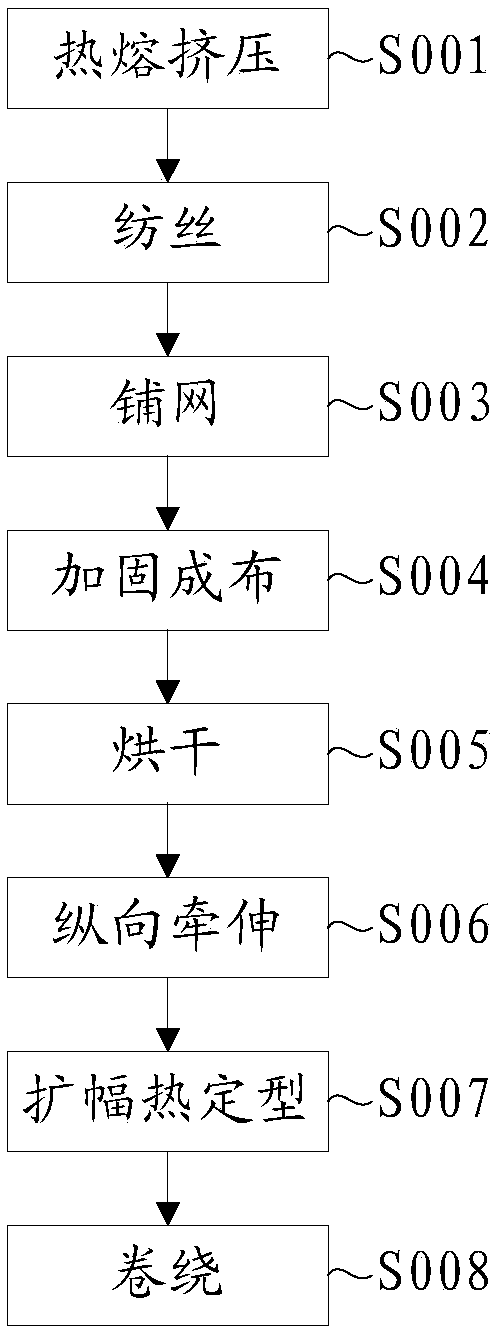

[0033] Such as figure 1 As shown, the spunbonded fabric of the present embodiment passes through screw extruder 1, spinning machine 2, web laying machine 3, jet spunlace spunlace machine 4, dryer 5, drafting machine 6, heat-setting by expansion Machine 7 and winding machine 8 are prepared. This example takes the preparation of spunbonded polypropylene spunlace fabric as an example. This preparation method can also prepare spunbonded polypropylene needle-punched fabric, spunbonded polyester spunlace non-woven fabric, spunbonded polyester needle-punched non-woven fabric, or other fiber spunbond nonwovens.

[0034] S...

Embodiment 2

[0055] This embodiment provides a kind of spunbond cloth, this spunbond cloth is prepared by the preparation method of the spunbond cloth of embodiment 1, so this spunbond cloth has the characteristics of high strength and low elongation deformation, thus this spunbond cloth Cloth can be applied to furniture, sofas, seats and other industries, with a wider range of applications and a longer service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com