A kind of yellow phosphorescent cu(i) complex luminescent material and preparation method thereof

A technology of luminescent materials and complexes, which is applied to luminescent materials, 1/11 group organic compounds without C-metal bonds, copper organic compounds, etc. Effects of radiation attenuation, increased transition probability, and improved light absorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

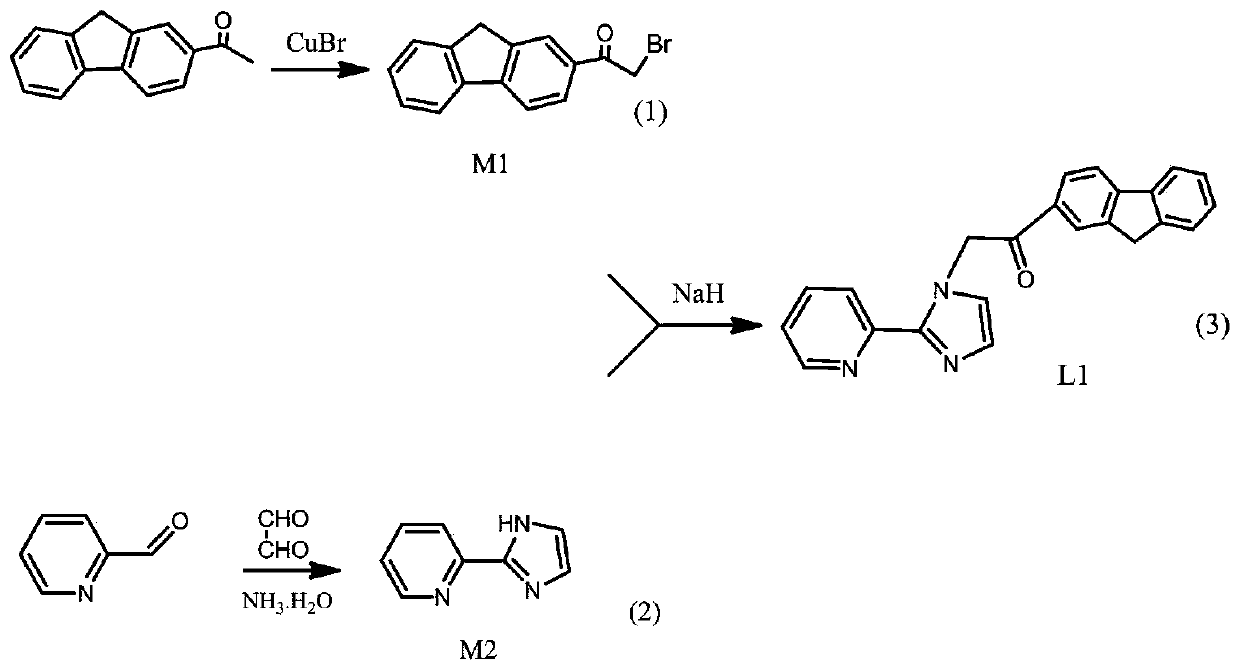

[0026] Synthesis of ligand L1 (2-OFPI).

[0027] As attached figure 1 The synthetic route is shown:

[0028] (1) Synthesis of ligand L1 (2-OFPI) precursor M1 (2-bromo-1-(9H-fluoren-2-yl)ethanone), the structural formula is: (III)

[0029]

[0030] Add copper bromide (2.68g, 12mmol) and 25mL of ethyl acetate into a 50mL round-bottom flask, transfer the above mixture to an oil bath, stir and reflux, and dissolve 2-acetyl fluorene (1.25g, 6mmol) In 13mL of dichloromethane solution, slowly add dropwise to the above solution. The addition is completed within 15 minutes. After stirring and refluxing for 3.5 hours, it is filtered through Celite while it is hot, washed with ethyl acetate several times, and the filtrate is rotated under reduced pressure. The solvent was removed by evaporation to obtain a grayish green solid.

[0031] (2) Synthesis of ligand L1 (2-OFPI) precursor M2 (2-(2-pyridyl) imidazole), the structural formula is: (VI)

[0032]

[0033] (3) Synthetic ligand L1 (2-OFPI):

[...

Embodiment 2

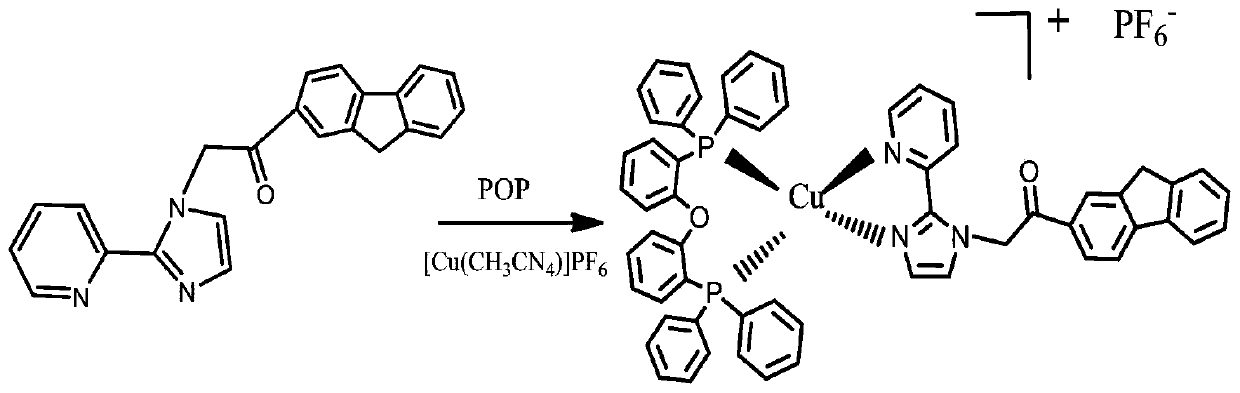

[0036] Phosphorescent complex Cu(2-OFPI)(POP)(PF 6 ) Synthesis: as attached image 3 As shown in the synthetic route, in a 50mL round-bottomed flask, add copper hexafluorophosphate tetraacetonitrile {[Cu(CH 3 CN) 4 ](PF 6 ) (0.062g, 0.2mmol)}, POP (0.108g, 0.2mmol) and dichloromethane solution (10mL), stirred at room temperature under nitrogen protection for 2h, and then 0.2mmol of ligand L1 (2-OFPI) was dissolved in the Inject the degassed dichloromethane solution into the above mixed solution, react at room temperature for 2 hours, filter the reacted solution through diatomaceous earth, and remove the solvent by rotary evaporation of the filtrate under reduced pressure to obtain a solid powder. The methane solution was dissolved, and a small amount of acetonitrile and a large amount of ether were added. A large amount of precipitation was observed. The precipitate was collected by filtration. The precipitate was washed several times with ether and dried to obtain the product. Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com