Soilless culture substrate and preparation method thereof

The technology of soilless culture substrate and expanded perlite is applied in the directions of planting substrate, botanical equipment and method, culture medium, etc., can solve the problems of small odor, single nutrient composition, limited source of raw materials, etc., and achieves low production cost, low preparation Simple method, nutrient-rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

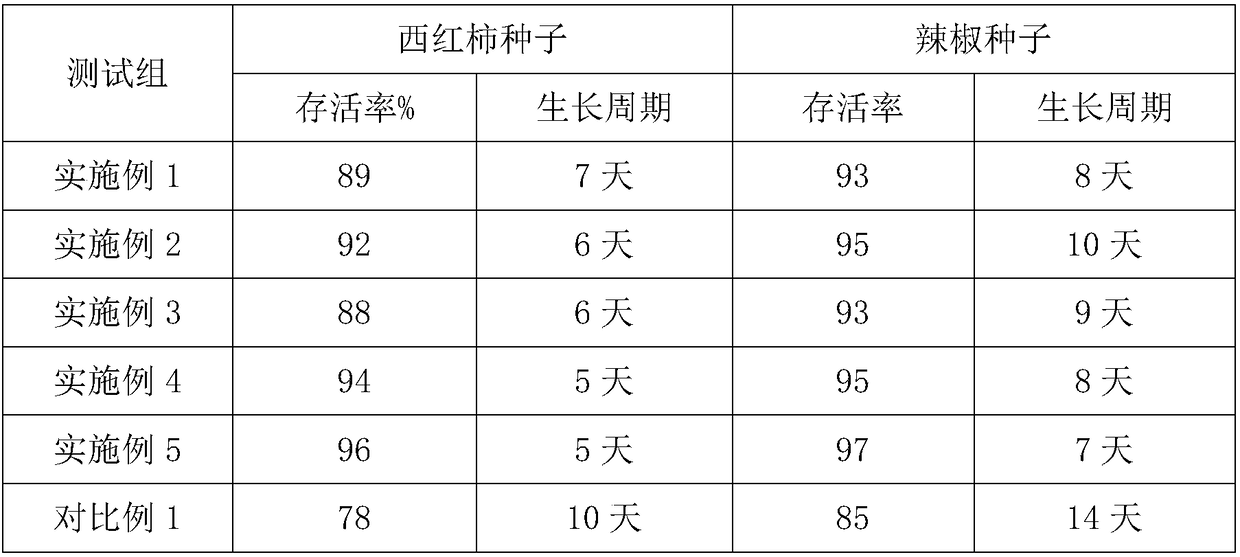

Examples

Embodiment 1

[0034] A soilless culture substrate, comprising the following raw materials by weight:

[0035] 30 parts of peat, 10 parts of coated expanded perlite, 6 parts of montmorillonite powder, 10 parts of plant ash, 10 parts of eggshell powder, 4 parts of waste asbestos powder, 10 parts of straw, 4 parts of bean dregs, 4 parts of potato dregs, rice husk powder 3 parts, 2 parts of cyclodextrin, 1 part of sodium hydroxymethyl cellulose, 3 parts of quicklime and 0.2 parts of trace elements.

[0036] The preparation method of coated expanded perlite is as follows:

[0037] (a) after placing the expanded perlite in a calciner and calcining at 350 degrees Celsius for 4 hours, drop into a ball mill and grind, and pass through a 100-mesh sieve;

[0038] (b) adding the expanded perlite treated in step (a) into a coating machine and heating to 220-230 degrees Celsius, and adding calcium carbonate powder, stirring uniformly to obtain a mixture;

Embodiment 2

[0051] A soilless culture substrate, comprising the following raw materials by weight:

[0052] 30-40 parts of peat, 10-15 parts of coated expanded perlite, 6-12 parts of montmorillonite powder, 10-15 parts of plant ash, 10-15 parts of eggshell powder, 4-9 parts of waste asbestos powder, 10-15 parts of straw parts, 4-9 parts of bean dregs, 4-9 parts of potato dregs, 3-7 parts of rice husk powder, 2-5 parts of cyclodextrin, 1-3 parts of sodium hydroxymethyl cellulose, 3-7 parts of quicklime and trace elements 0.2-0.8 servings.

[0053] Preferably, it includes the following raw materials in parts by weight: 32-38 parts of peat, 11-14 parts of coated expanded perlite, 8-10 parts of montmorillonite powder, 12-14 parts of plant ash, 11-14 parts of eggshell powder, discarded 5-8 parts of asbestos powder, 11-14 parts of straw, 5-8 parts of bean dregs, 5-8 parts of potato dregs, 4-6 parts of rice husk powder, 3-4 parts of cyclodextrin, 1.5 parts of sodium hydroxymethyl cellulose 2.5...

Embodiment 3

[0070] A soilless culture substrate, comprising the following raw materials by weight:

[0071] 30-40 parts of peat, 10-15 parts of coated expanded perlite, 6-12 parts of montmorillonite powder, 10-15 parts of plant ash, 10-15 parts of eggshell powder, 4-9 parts of waste asbestos powder, 10-15 parts of straw parts, 4-9 parts of bean dregs, 4-9 parts of potato dregs, 3-7 parts of rice husk powder, 2-5 parts of cyclodextrin, 1-3 parts of sodium hydroxymethyl cellulose, 3-7 parts of quicklime and trace elements 0.2-0.8 servings.

[0072] Preferably, it includes the following raw materials in parts by weight: 32-38 parts of peat, 11-14 parts of coated expanded perlite, 8-10 parts of montmorillonite powder, 12-14 parts of plant ash, 11-14 parts of eggshell powder, discarded 5-8 parts of asbestos powder, 11-14 parts of straw, 5-8 parts of bean dregs, 5-8 parts of potato dregs, 4-6 parts of rice husk powder, 3-4 parts of cyclodextrin, 1.5 parts of sodium hydroxymethyl cellulose 2.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com