Non-machine-room elevator speed limiter

A machine room-less elevator and speed limiter technology, which is applied in elevators, transportation and packaging, etc., can solve the problems of potential safety hazards, the inability to remotely realize manual trigger braking, manual reset braking and manual remote reset of electrical switches, etc., to increase safety Sex, the effect of reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

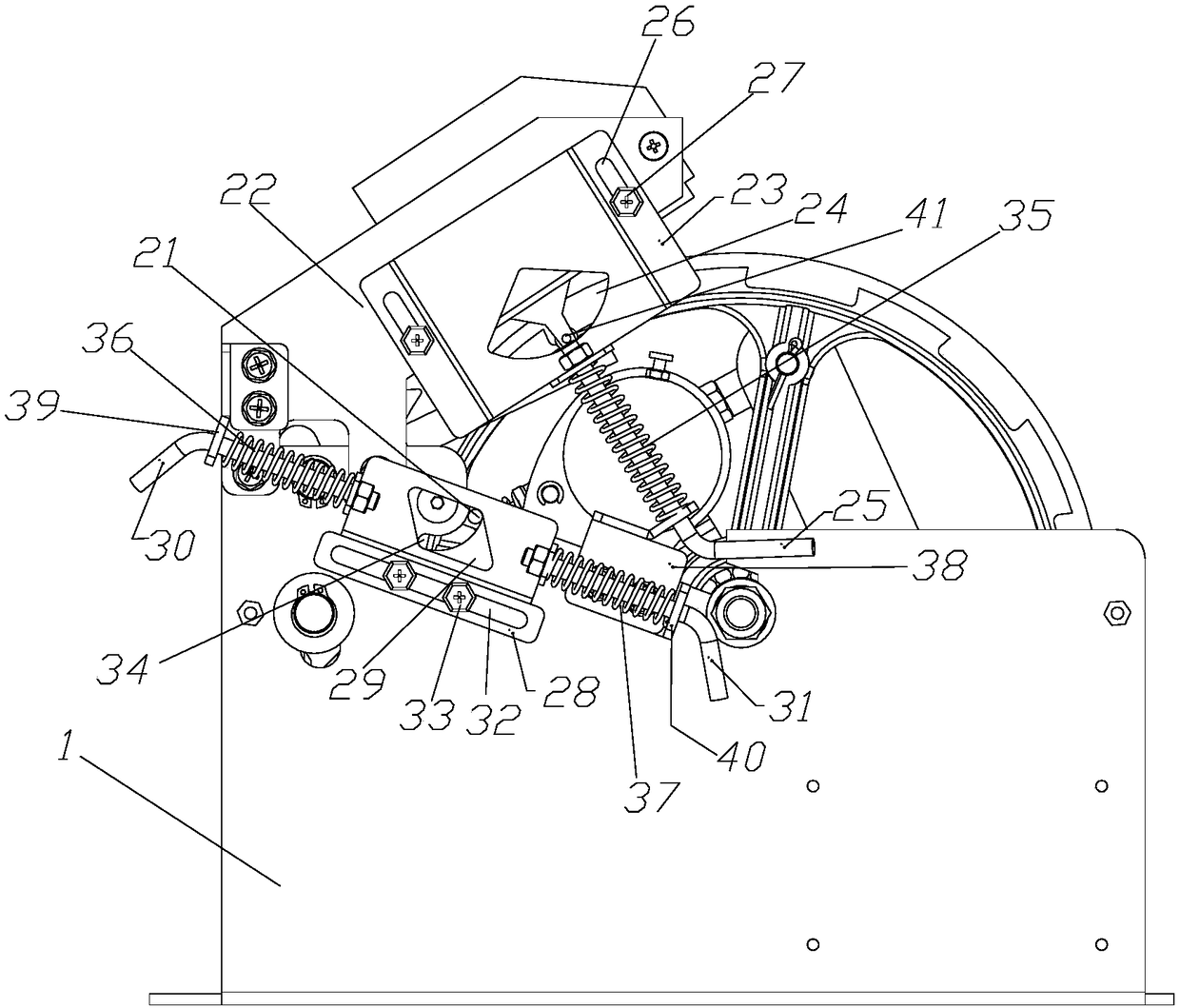

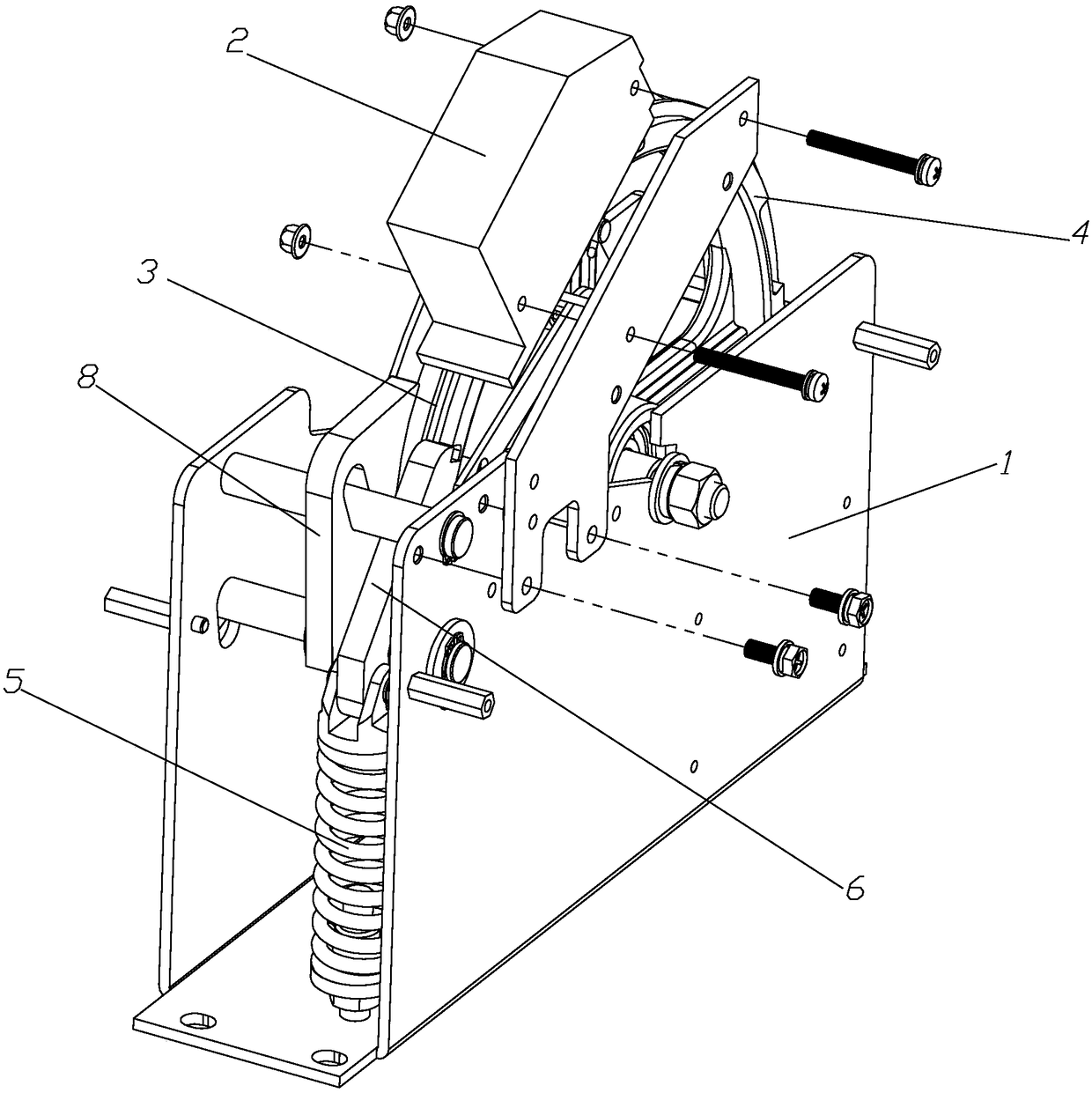

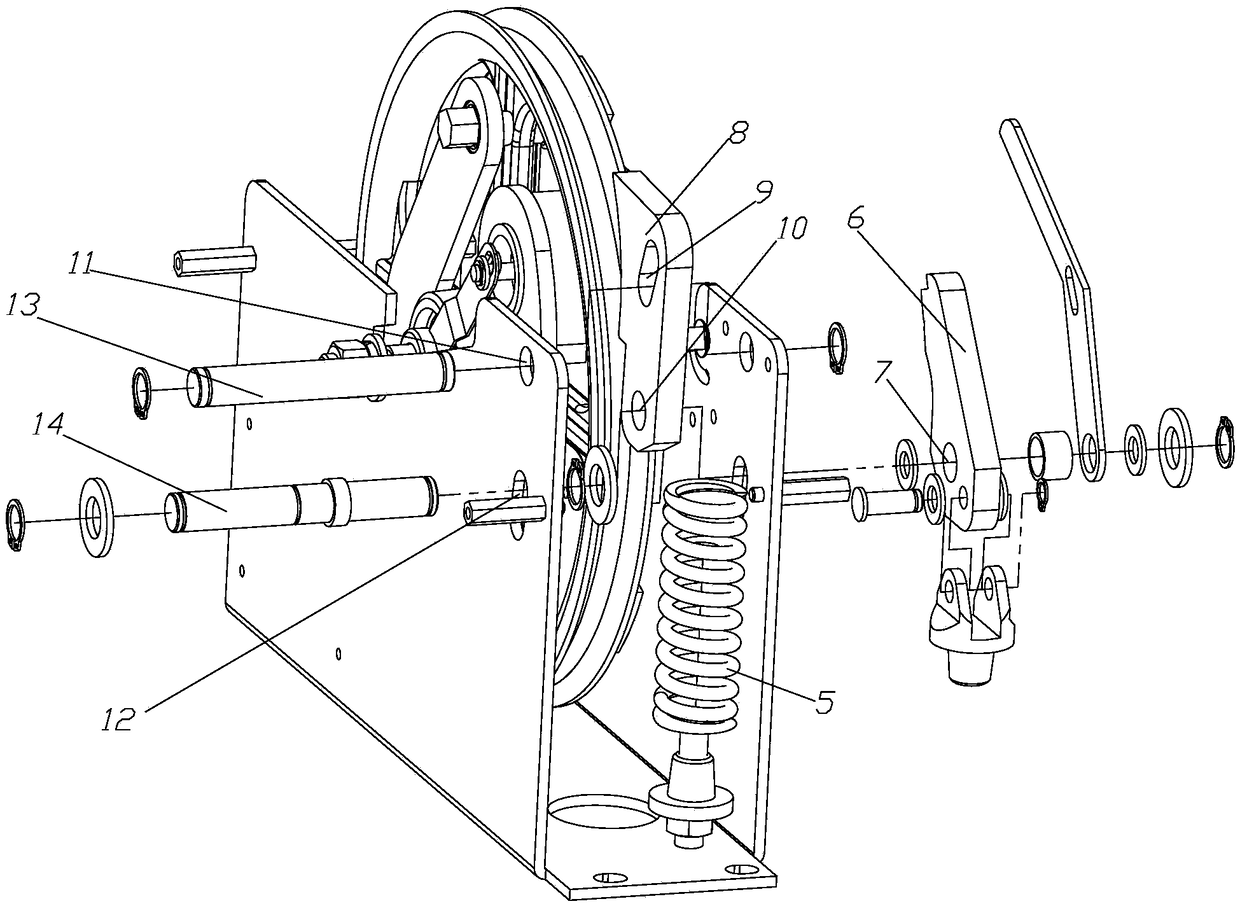

[0028] Such as Figure 1 to Figure 3 The machine-room-less elevator speed limiter shown includes a bracket 1, and a speed limiter switch 2 is installed on the upper part of the bracket 1. The speed limiter switch is provided with a reset screw 41 that drives the speed limiter switch to reset. The support 1 includes a bottom plate and the side wall, the bracket 1 is provided with a sheave assembly, the sheave assembly includes a sheave mechanism 3 and a ratchet mechanism 4 for winding the wire rope, a brake assembly is provided on one side of the sheave assembly, and includes The block assembly 15 hinged on the side wall is used to trigger the brake assembly to work. The sheave mechanism 3 is also provided with a pituitary assembly that drives the block assembly 15 to rotate. One side of the block assembly is provided with The drive rod 21 prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com