Protective tool for end tooth blasting prohibited area and shot blasting method thereof

A technology for protecting tooling and end teeth, which is applied in the field of surface treatment of parts, can solve the problems of shortening the processing cycle and low protection accuracy of the no-spray area, and achieve the effect of shortening the processing cycle, meeting the needs of large-scale production and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

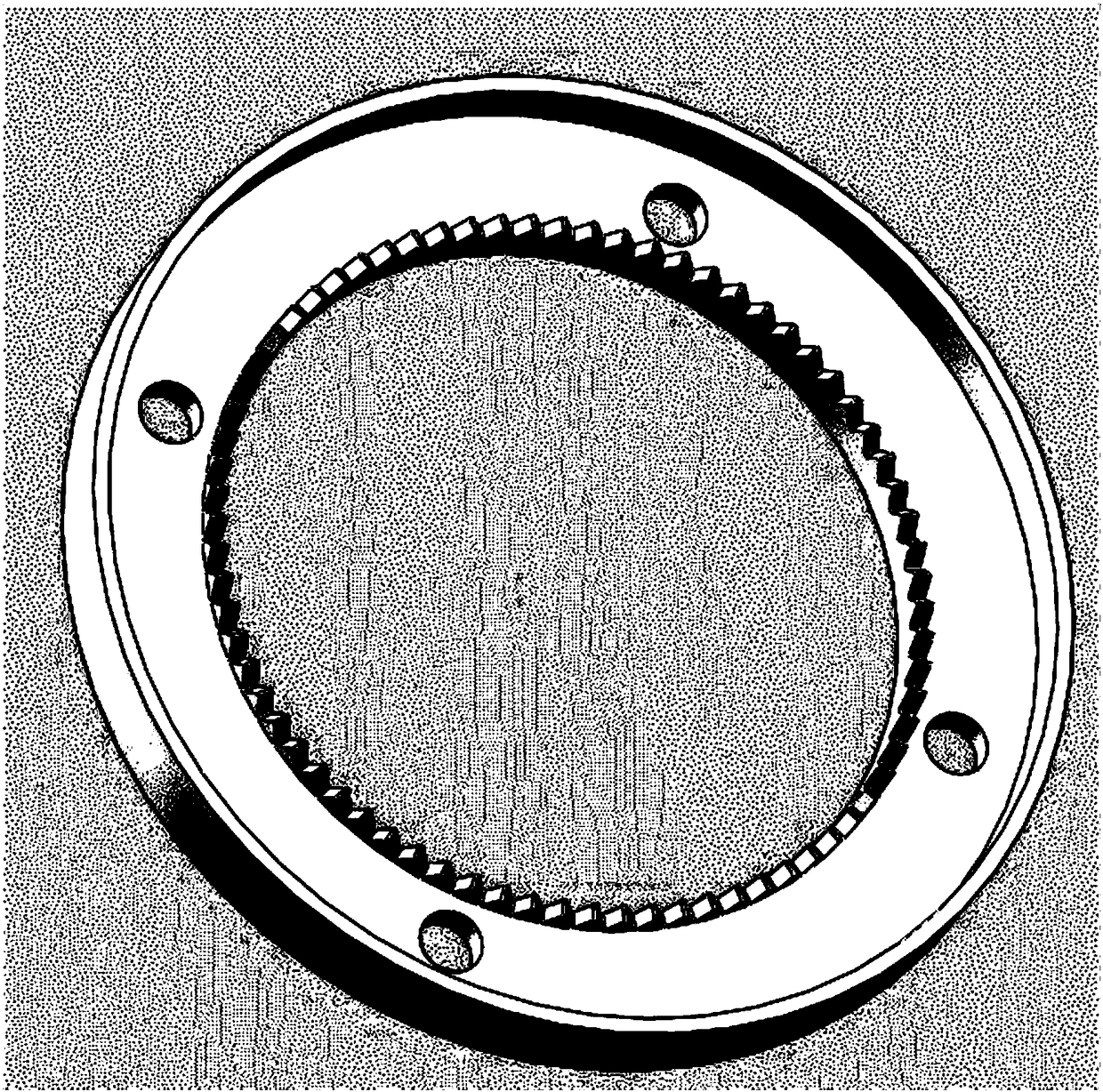

[0016] The protected end teeth are arranged radially, forming a ring shape, and there is a phenomenon of structural interference. The protective tooling of the prepared dentate no-spray area is as follows: figure 1 As shown, the tooling is made of polytetrafluoroethylene and is in the shape of a ring. The inner diameter of the ring is 50cm, which is consistent with the inner diameter of the protected end tooth; the outer diameter of the ring is 100cm, which is larger than the outer diameter of the protected end tooth. 5%, the thickness of the ring is 10cm, which is 30% larger than the height of the protected end teeth; the upper end of the ring is flat, and the inner side of the lower end of the ring is densely covered with end teeth. The number of end teeth is 73, which is the same as the protected end teeth. The shape and quantity of the end teeth are consistent, and the length of the end teeth is 1 / 2 of the length of the protected end teeth; there is an annular boss on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com