A method for precise control of billet moving speed

A technology of moving speed and precise control, applied in manufacturing tools, metal processing equipment, measuring/indicating equipment, etc., can solve the problem of inaccurate measurement of the moving speed of the casting billet, and achieve a simple and effective structure, reasonable matching, and convenient realization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Attached below Figure 1-2 The present invention is further described with embodiment:

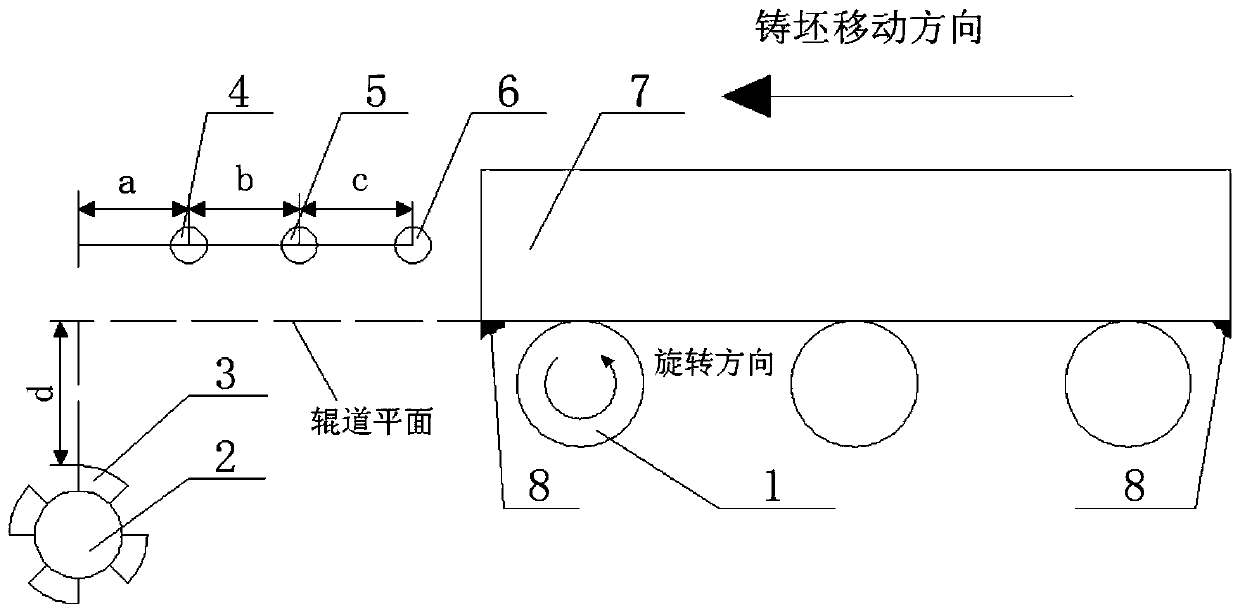

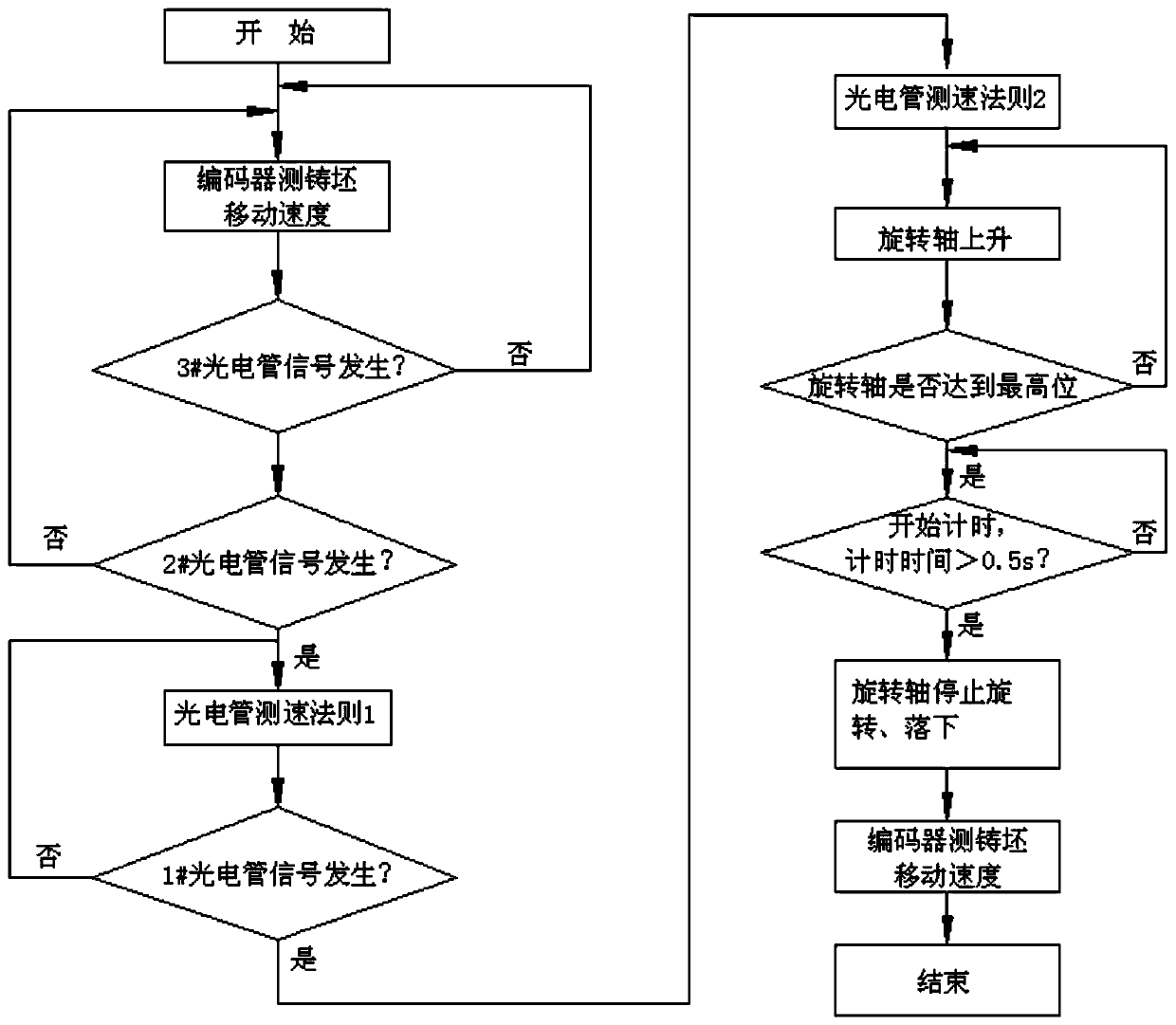

[0026] as attached figure 1 , figure 2 Shown: the deburring machine equipment based on the precise control method of casting slab moving speed according to the present invention includes at least a roller table 1, a rotating shaft 2, a blade 3, a first photoelectric cell 4, a second photoelectric cell 5, a third photoelectric cell Tube 6. The casting slab 7 passes through the roller table 1, and there is a burr 8 under the casting slab 7 that needs to be removed. Each roller table 1 is equipped with a photoelectric encoder for speed measurement.

[0027] The equipment composition and working process of the deburring machine are as follows: the roller table 1 mainly pushes the cast slab 7 to move forward along the roller table plane above the roller table 1 through its own rotation; the rotating shaft 2 is set at a set distance in front of the frontmost roller table 1 , the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com