Device for providing deep magnetic path spiral magnetic field to regulate and control movement of magnetic particle groups in ore pulp

A technology of helical magnetic field and magnetic particles, which is applied in the field of regulation and optimization of mineral processing process, can solve the problems of ineffective magnetic catalyst, inability to guarantee the magnetic field strength, and poor leading effect, etc., to avoid inclusions, effectively flocculate, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

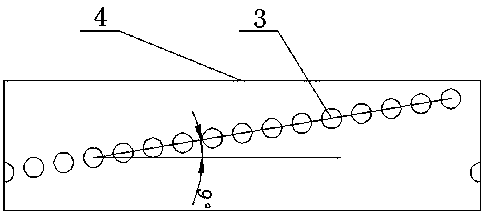

[0027] Such as figure 1 , figure 2 , image 3 As shown, a device of this embodiment that provides a deep magnetic helical magnetic field to regulate the movement of magnetic particle groups in the pulp includes a frame 1, an upper support plate 13 is fixed above the frame 1, and an upper support plate 13 is arranged on the upper support plate. The aluminum swivel 4 above 13, the swivel connecting plate 9, the rotating shaft 6, the inner support rod 7, and the container support ring 8, the inner wall of the aluminum swivel 4 is inlaid with NdFeB spirally distributed from bottom to top Magnetic steel 3, the magnetization method of the NdFeB magnetic steel 3 is radial magnetization, the polarity of two adjacent NdFe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com