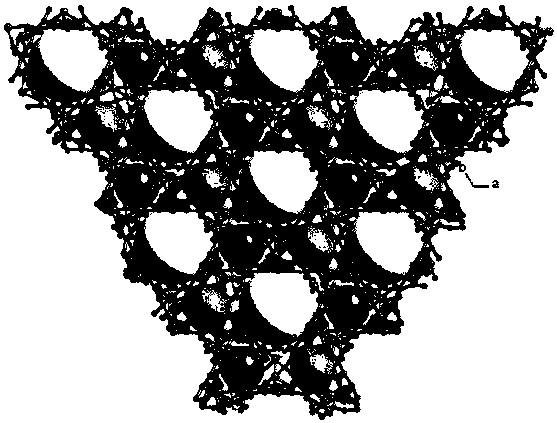

Preparation method and application of copper metal organic framework compound

An organic framework and compound technology, applied in the field of preparation of copper metal organic framework compounds, can solve the problems of high production cost of carbon nanotubes, unsatisfactory adsorption effect, difficult regeneration of activated carbon, etc., and achieves high yield, simple preparation method, high The effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

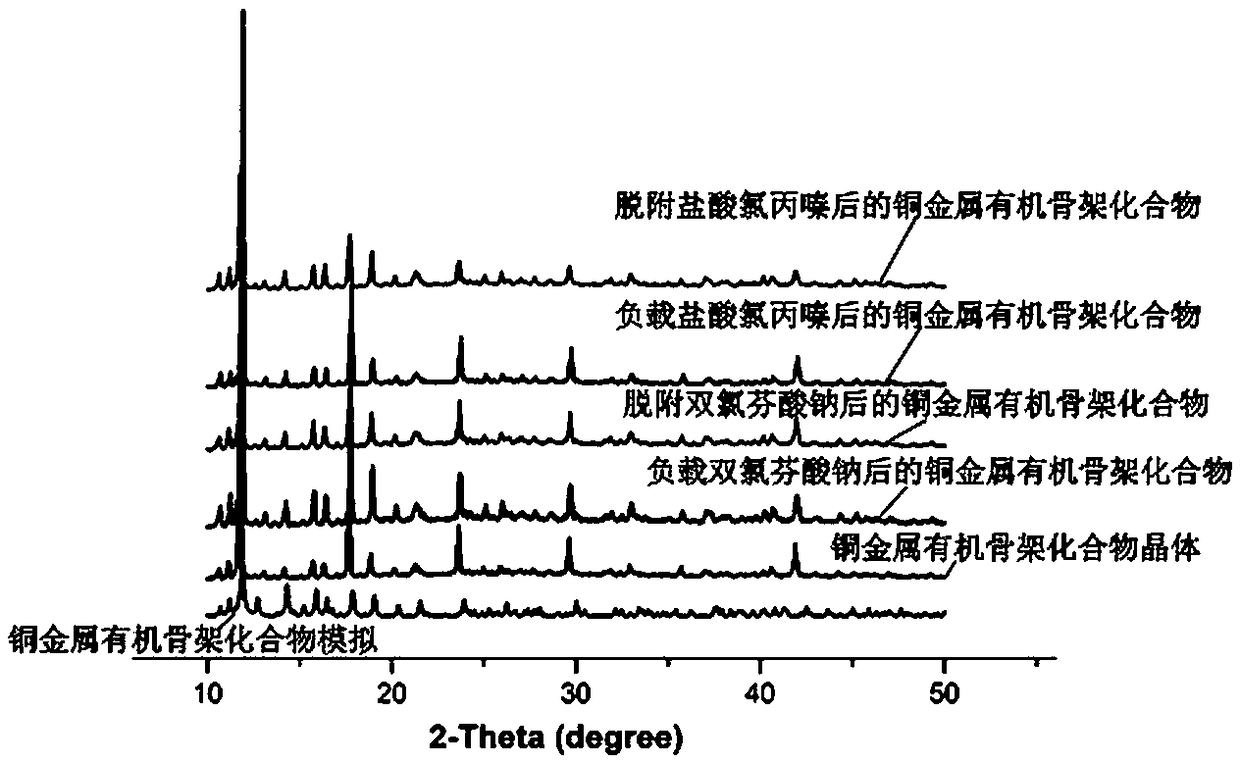

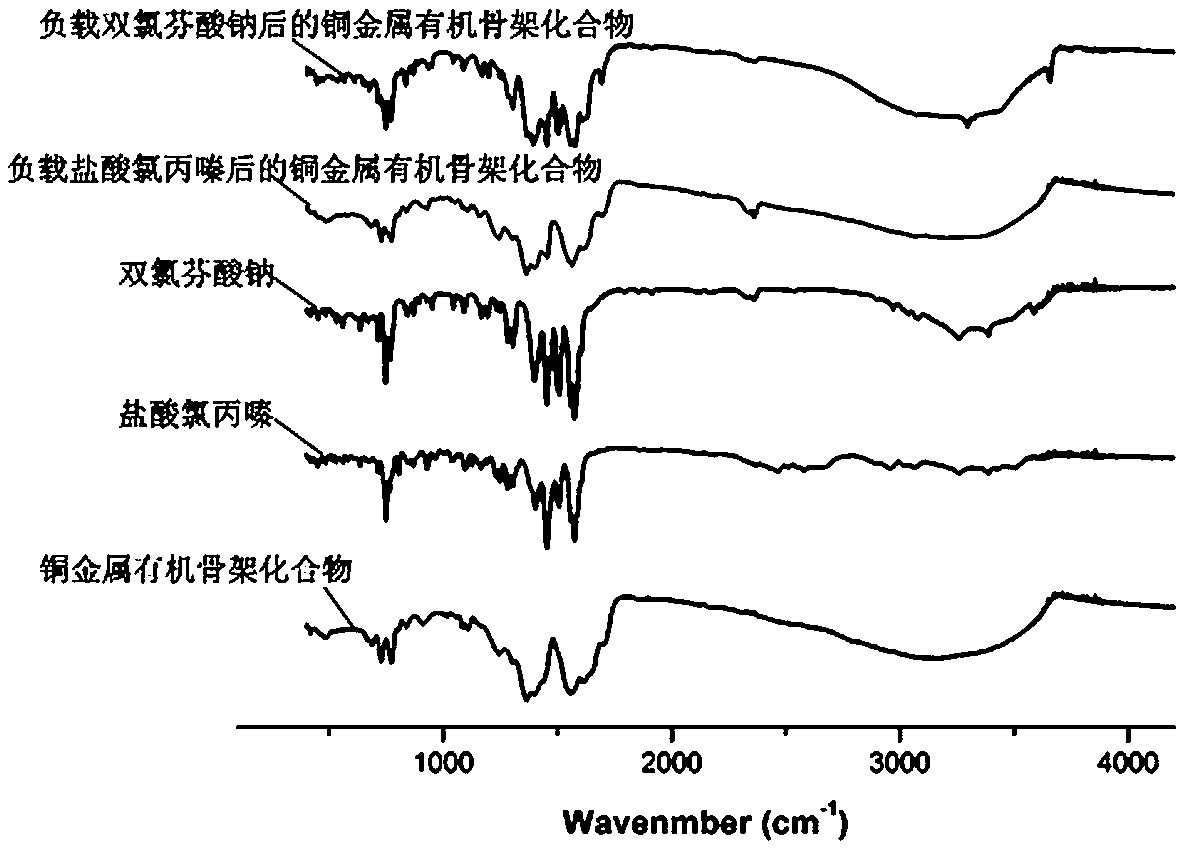

Image

Examples

Embodiment 1

[0032] A preparation method of a copper metal organic framework compound, comprising the following steps:

[0033] 1) Mix 2.7g of copper nitrate and 0.9g of 2,5-bis(3',5'-dicarboxyphenyl)-benzoic acid, add 166mL of water and N,N-dimethylformamide mixed solution and stir 3min, then add 11mL of fluoboric acid and stir for 8min to obtain a mixed solution A, wherein the volume ratio of water and N,N-dimethylformamide is 1:1;

[0034] 2) Place the glass bottle sealed with the mixed solution A obtained in step 1) at a temperature of 85°C for 12 hours to obtain crystal B;

[0035] 3) Wash the crystal B obtained in step 2) with ethanol three times, then place the cleaned crystal B in ethanol for 1 day, and replace the ethanol every 12 hours during this period, and finally place the soaked crystal B Dry in an oven at 90° C. for 12 hours to obtain the copper metal organic framework compound.

Embodiment 2

[0037] A preparation method of a copper metal organic framework compound, comprising the following steps:

[0038] 1) Mix 2.7g of copper nitrate and 0.9g of 2,5-bis(3',5'-dicarboxyphenyl)-benzoic acid, add 186mL of water and N,N-dimethylformamide mixed solution and stir 8min, then add 14.3mL fluoboric acid and stir for 3min to obtain mixed solution A, wherein the volume ratio of water and N,N-dimethylformamide is 1:1;

[0039] 2) Place the glass bottle sealed with the mixed solution A obtained in step 1) at a temperature of 95°C for 8 hours to obtain crystal B;

[0040] 3) Wash the crystal B obtained from step 2) with ethanol three times, then place the cleaned crystal B in ethanol for 3 days, and replace the ethanol every 12 hours during this period, and finally place the soaked crystal B Dry in an oven at a temperature of 110° C. for 8 hours to obtain a copper metal organic framework compound.

Embodiment 3

[0042]A preparation method of a copper metal organic framework compound, comprising the following steps:

[0043] 1) Mix 2.7g of copper nitrate and 0.9g of 2,5-bis(3',5'-dicarboxyphenyl)-benzoic acid, add 180mL of water and N,N-dimethylformamide mixed solution and stir 5min, then add 18mL of fluoboric acid and stir for 5min to obtain a mixed solution A, wherein the volume ratio of water and N,N-dimethylformamide is 1:1;

[0044] 2) Place the glass bottle sealed with the mixed solution A obtained in step 1) at a temperature of 90°C for 10 hours to obtain crystal B;

[0045] 3) Wash the crystal B obtained from step 2) with ethanol three times, then place the cleaned crystal B in ethanol for 2 days, and replace the ethanol every 12 hours during this period, and finally place the soaked crystal B Dry in an oven at 100°C for 10 hours to obtain the copper metal organic framework compound.

[0046] In conclusion, the preparation method of copper metal organic framework compound is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com