Filter felt for dedusting and purification of flue gas and preparation method

A filter felt and flue gas technology, which is applied in the field of flue gas purification, can solve the problems of high hazard, ineffective catalyst catalytic reduction, and inability to realize the integration of dust removal and denitrification, etc., and achieve the effect of prolonging the working life and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

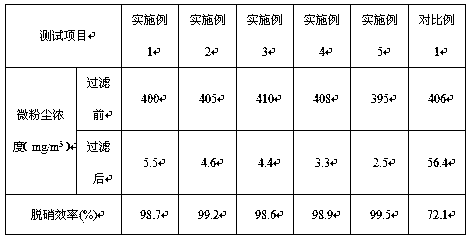

Examples

Embodiment 1

[0032] a. Mix carbon nanotubes with ammonium metavanadate, titanium dioxide, and oxalic acid solution, and heat to prepare a catalytically active solution;

[0033] b. Immerse the silica airgel felt in the catalytically active solution of step a, take it out after 25 minutes and pre-burn it to obtain a pre-fired felt;

[0034] c. Mix and grind hydrotalcite, silicon dioxide, aluminum oxide, indium oxide, zeolite, natural clay and water, and add binder and foaming agent to make slurry;

[0035] d. Coating the slurry in step c on the surface of the calcined felt in step b, and further calcining to prepare a filter felt for flue gas dust removal and purification.

[0036] In the step b, the average thickness of the silica airgel felt is 2mm; in the step c, the adhesive is an epoxy resin adhesive; in the step c, the foaming agent is potassium bicarbonate;

[0037] In step a, the heating temperature is 45°C, and the holding time is 15 minutes; in step b, the pre-calcination tempera...

Embodiment 2

[0040] a. Mix carbon nanotubes with ammonium metavanadate, titanium dioxide, and oxalic acid solution, and heat to prepare a catalytically active solution;

[0041] b. Immerse the silica airgel felt in the catalytically active solution of step a, take it out after 20 minutes and pre-burn it to obtain a pre-fired felt;

[0042]c. Mix and grind hydrotalcite, silicon dioxide, aluminum oxide, indium oxide, zeolite, natural clay and water, and add binder and foaming agent to make slurry;

[0043] d. Coating the slurry in step c on the surface of the calcined felt in step b, and further calcining to prepare a filter felt for flue gas dust removal and purification.

[0044] In step b, the average thickness of the silica airgel felt is 3 mm; in step c, the adhesive is a phenolic resin adhesive; in step c, the foaming agent is sodium bicarbonate;

[0045] In step a, the heating temperature is 50°C, and the holding time is 10 minutes; in step b, the pre-calcination temperature is 300°C...

Embodiment 3

[0048] a. Mix carbon nanotubes with ammonium metavanadate, titanium dioxide, and oxalic acid solution, and heat to prepare a catalytically active solution;

[0049] b. Immerse the silica airgel felt in the catalytically active solution of step a, take it out after 30 minutes and pre-burn it to obtain a pre-fired felt;

[0050] c. Mix and grind hydrotalcite, silicon dioxide, aluminum oxide, indium oxide, zeolite, natural clay and water, and add binder and foaming agent to make slurry;

[0051] d. Coating the slurry in step c on the surface of the calcined felt in step b, and further calcining to prepare a filter felt for flue gas dust removal and purification.

[0052] In the step b, the average thickness of the silica airgel felt is 2mm; in the step c, the adhesive is an epoxy resin adhesive; in the step c, the foaming agent is calcium bicarbonate;

[0053] In step a, the heating temperature is 40°C, and the holding time is 20min; in step b, the pre-calcination temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com