Harvester for rotten vegetable leaves in fields

A technology for harvesters and tail vegetables, applied to harvesters, loaders, crop processors, etc., can solve problems such as high water content, poor fermentation effect, and diseased crops in the next stubble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

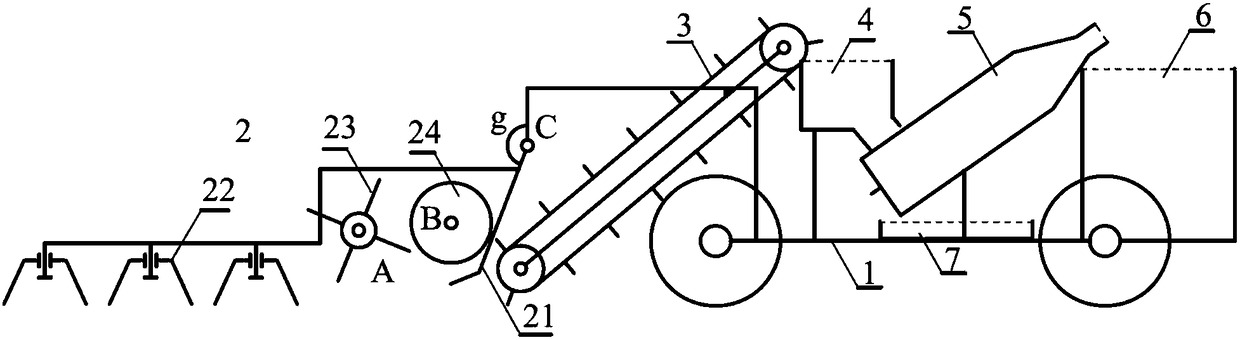

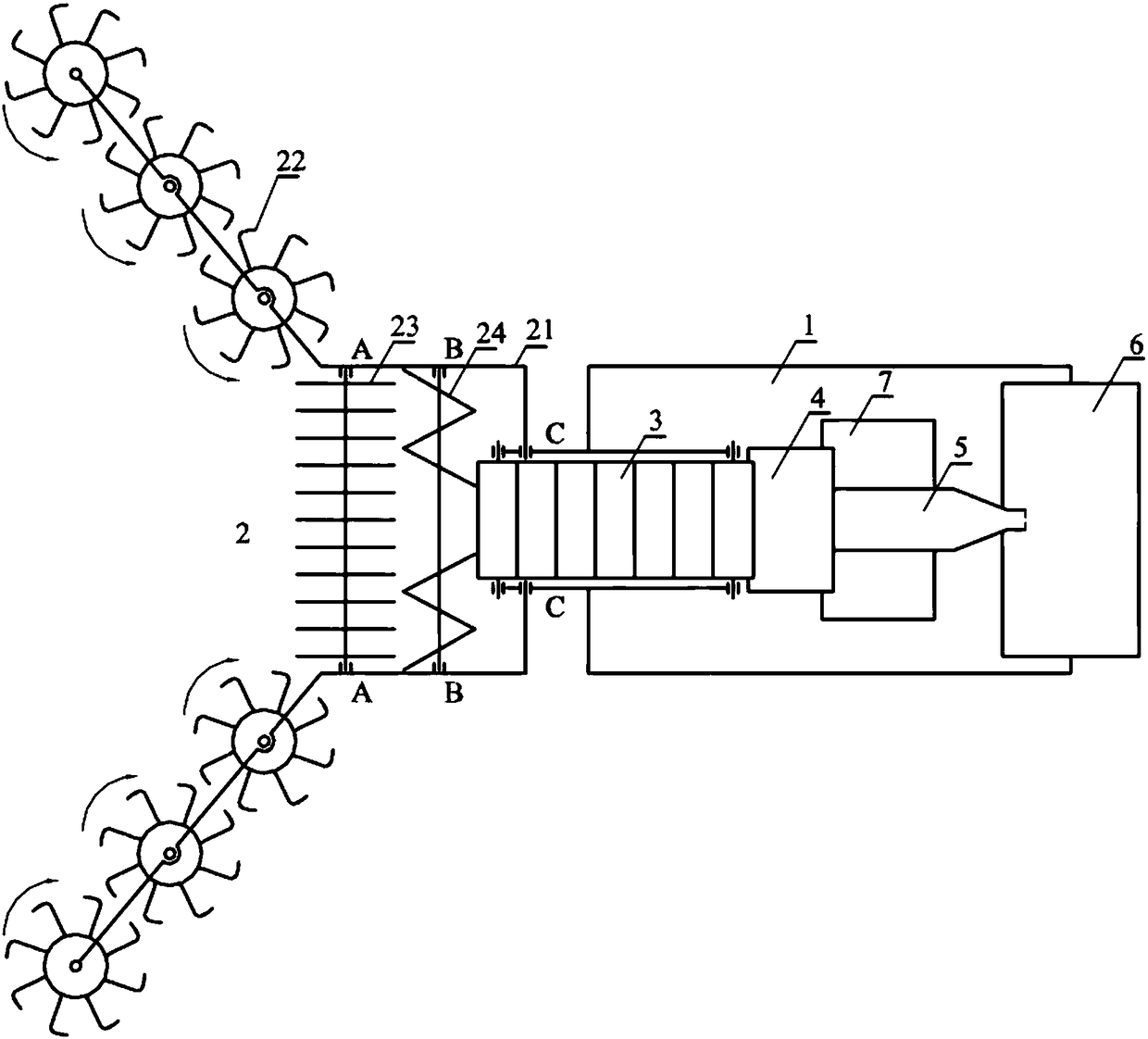

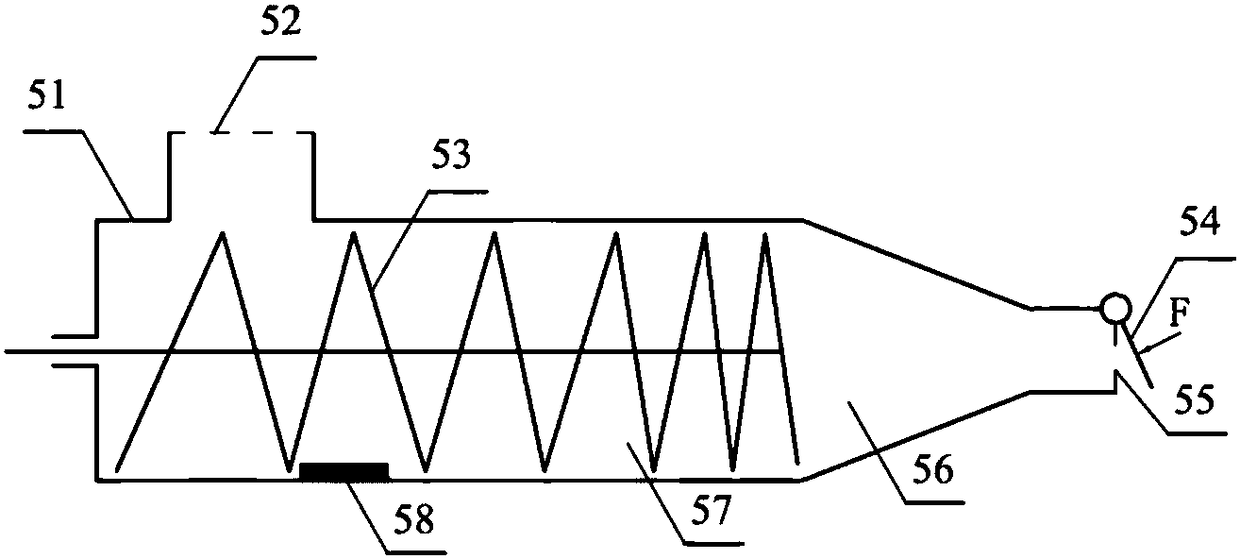

[0020] figure 1 The schematic diagram of the main view of the field vegetable harvester is shown. The field vegetable harvester includes: chassis 1, collection device 2, conveyor belt 3, crusher 4, screw press 5, collection box 6, juice collection box 7, Among them, the collection device 2, the conveyor belt 3, the crusher 4, the screw press 5, the juice collection box 7, and the collection box 6 are sequentially arranged on the body of the chassis 1 from front to back. Device 2, the collecting device 2 and the body of the chassis 1 are rotationally connected at point C in the longitudinal vertical plane, and the rotation axis CC (such as figure 2 shown), the posture of the collection device 2 is controlled and locked by the included angle g, one end of the conveyor belt 3 receives the tail vegetables f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com