Safety type lithium battery and preparation method thereof

A lithium battery and safety technology, applied in the field of safety lithium battery and its preparation, can solve the problems of safety threats, poor pressure relief control accuracy, easy corrosion of explosion-proof devices, etc., and achieve the effect of ensuring normal operation and preventing flatulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

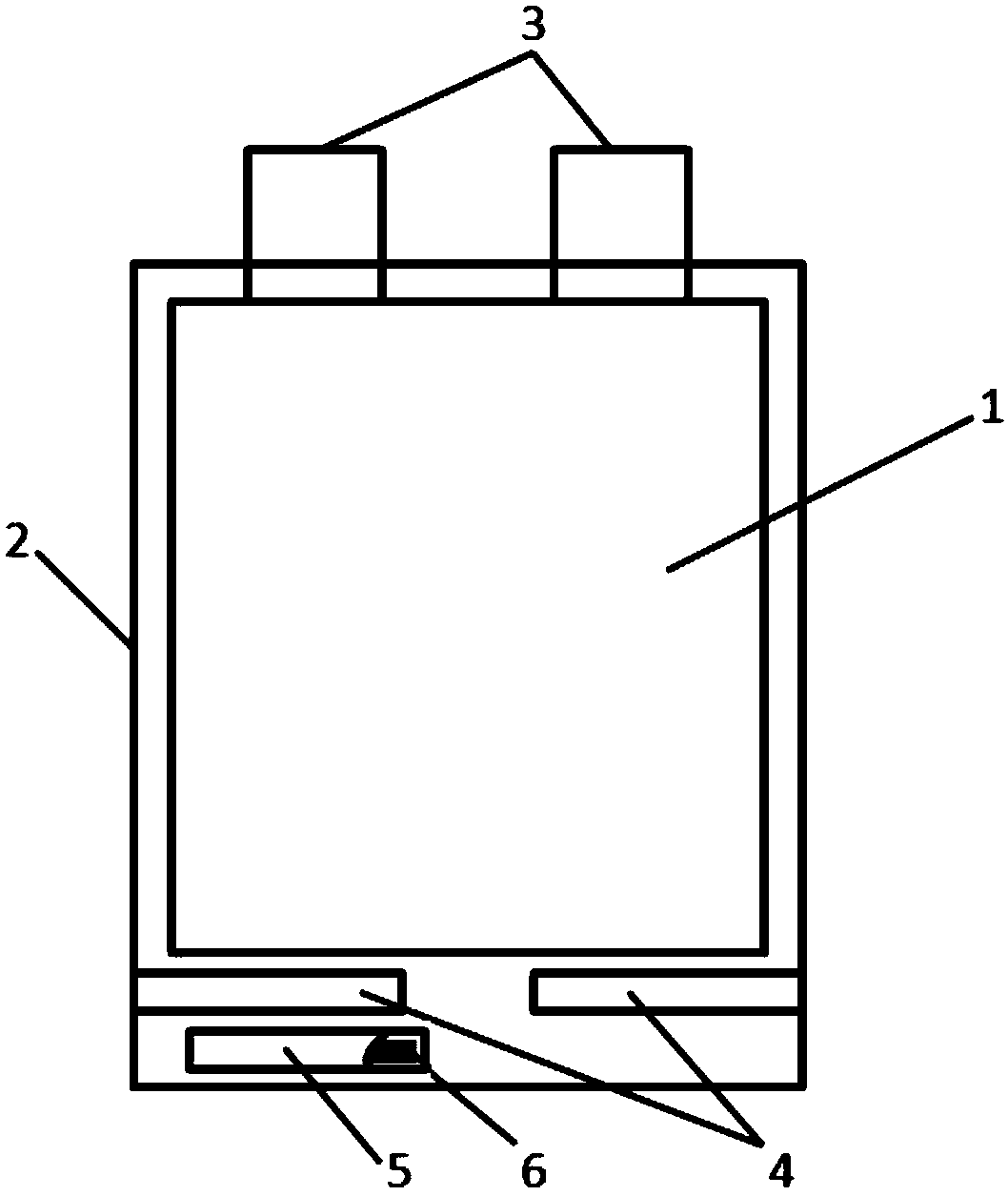

[0024] Take 22 sheets of positive electrodes and 23 sheets of negative electrodes coated with separators, stack them in sequence according to the negative electrode, positive electrode, and negative electrode to prepare the battery cell 1, and weld the positive and negative electrode lugs 3. Afterwards, the aluminum-plastic film 2 is used to package the battery cell, such as figure 1 , encapsulate the upper side (side of the pole ear), the left side of the battery, and reserve part of the space at the bottom of the battery cell. This space communicates with the cell area, and then put the material bag 5 with the gas adsorbent 6 into the reserved space inside the battery. The pore size of the material bag is 100nm, and the gas adsorption body is activated carbon with a mass of 10g. The battery can be completely packaged after the battery cell is vacuum baked. After the battery is prepared, 100g of electrolyte is injected, and it is left for 24 hours before pre-charging. Final...

Embodiment 2

[0026] Take 22 sheets of positive electrodes and 23 sheets of negative electrodes coated with separators, stack them in sequence according to the negative electrode, positive electrode, and negative electrode to prepare the battery cell 1, and weld the positive and negative electrode lugs 3. Afterwards, the aluminum-plastic film 2 is used to package the battery cell, such as figure 1 , encapsulate the upper side (side of the pole ear), the left side of the battery, and reserve part of the space at the bottom of the battery cell. This space communicates with the cell area, and then put the material bag 5 with the gas adsorbent 6 into the reserved space inside the battery. The pore size of the material bag is 600nm, and the gas adsorption body is activated carbon with a mass of 2g. The battery can be completely packaged after the battery cell is vacuum baked. After the battery is prepared, 100g of electrolyte is injected, and it is left for 24 hours before pre-charging. Finall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com