Negative pressure type roller dryer

A drum dryer, negative pressure technology, applied in non-progressive dryers, dryers, grain drying, etc., can solve problems such as excessive moisture and moisture return, reduce humidity and pressure, prevent water absorption and moisture return, and avoid burnt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

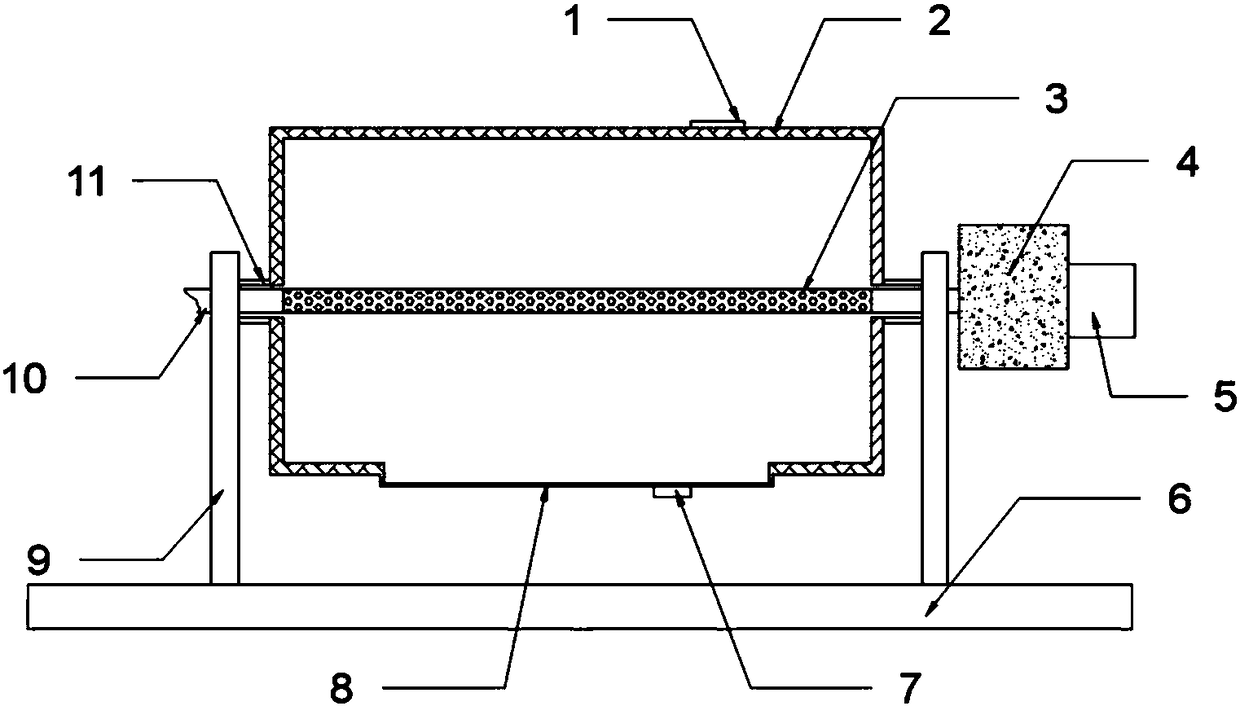

[0026] A negative pressure drum dryer includes a base 6, a bracket 9 mounted on the base, and a drying cylinder 1 that is rotatably matched with the bracket 9 through a shaft 11; the top of the drying cylinder 2 is provided with a feed hole 1, and A discharge port 8 is provided at the bottom; it is characterized in that: the shaft 7 is provided with a shaft hole; a heating layer is integrated in the wall of the drying cylinder 2; a hollow structure is installed in the cylinder cavity of the drying cylinder 2 Ventilation tube 10; the two ends of the ventilation tube 2 extend out of the shaft hole and pass through the bracket; the ventilation tube 3 is located on the tube wall inside the drying cylinder 3 with ventilation holes 3.

Embodiment 2

[0028] Based on Example 1, in order to improve the moisture absorption efficiency of the air flowing through the ventilation pipe, the following improvements are made: a drying device is provided at one end of the ventilation pipe 10; the drying device includes a drying box 4 and an inlet set on the drying box 4 Tuyere 5; The inside of the drying box 4 is filled with desiccant.

[0029] Through the action of the drying device, the humidity of the air flowing through the inside of the ventilation pipe is reduced, and the humidity difference between the inside of the ventilation pipe and the inside of the drying cylinder is enlarged. Driven by the physical action of the humidity difference, the moisture in the drying cylinder can more easily escape into the ventilation pipe through the ventilation holes and be taken out, which further reduces the humidity in the drying cylinder and reduces the moisture regain of grain particles in the subsequent cooling step.

Embodiment 3

[0031] Based on Example 1, in order to reduce the influence of the resistance of the drying box on the speed of air flowing into the ventilation pipe, the following improvement is made: the diameter of the air inlet 5 is larger than the diameter of the ventilation pipe 10.

[0032] Through the design of the air inlet size, the drying box is equipped with the function of a booster device. The colleagues who counteract its resistance can maintain or increase the flow rate of the air after passing through the drying box, thereby ensuring the negative pressure effect generated by the ventilation pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com