Thick coal seam wide-roadway tunneling and gangue paste body filling roadway forming method

A paste filling and thick coal seam technology, which is applied in the direction of filling, earth square drilling, ground mining, etc., can solve the problems of large gangue output, human living conditions and environmental hazards, and reduce the cost of excavation and ensure stability and high efficiency. Efficiency performance, the effect of reducing roof hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention proposes a gangue paste filling system for thick coal seam and wide roadway excavation. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

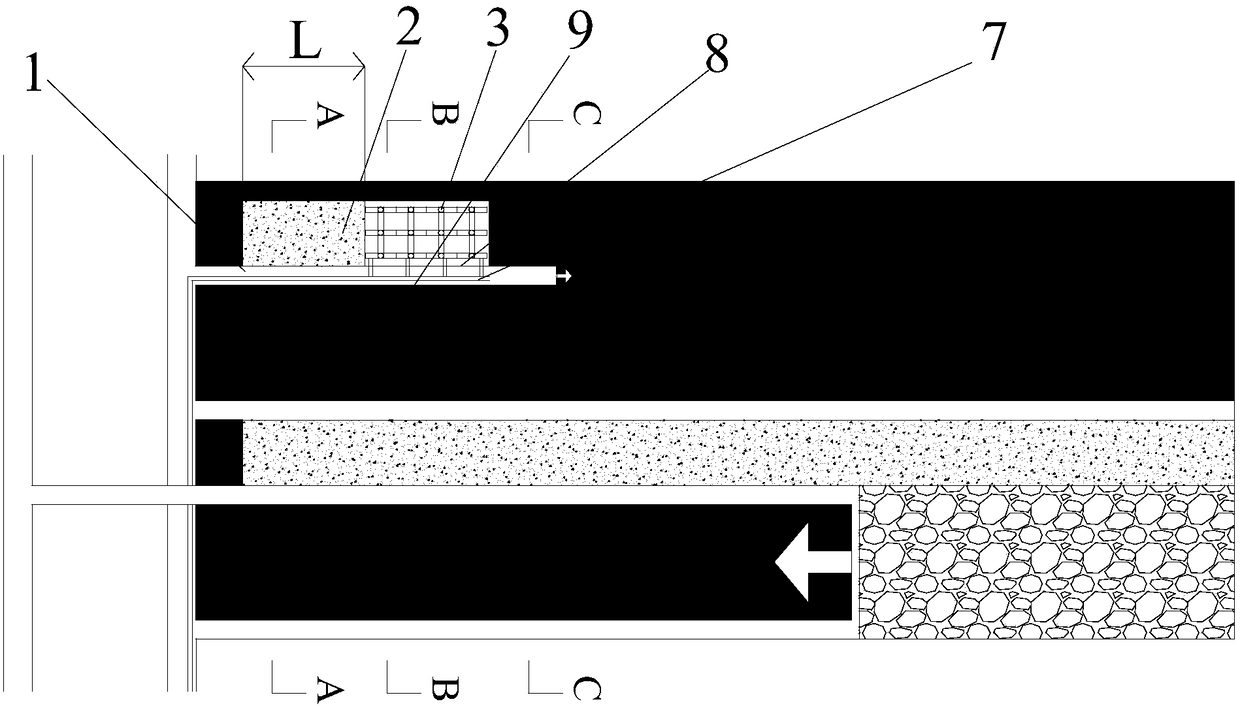

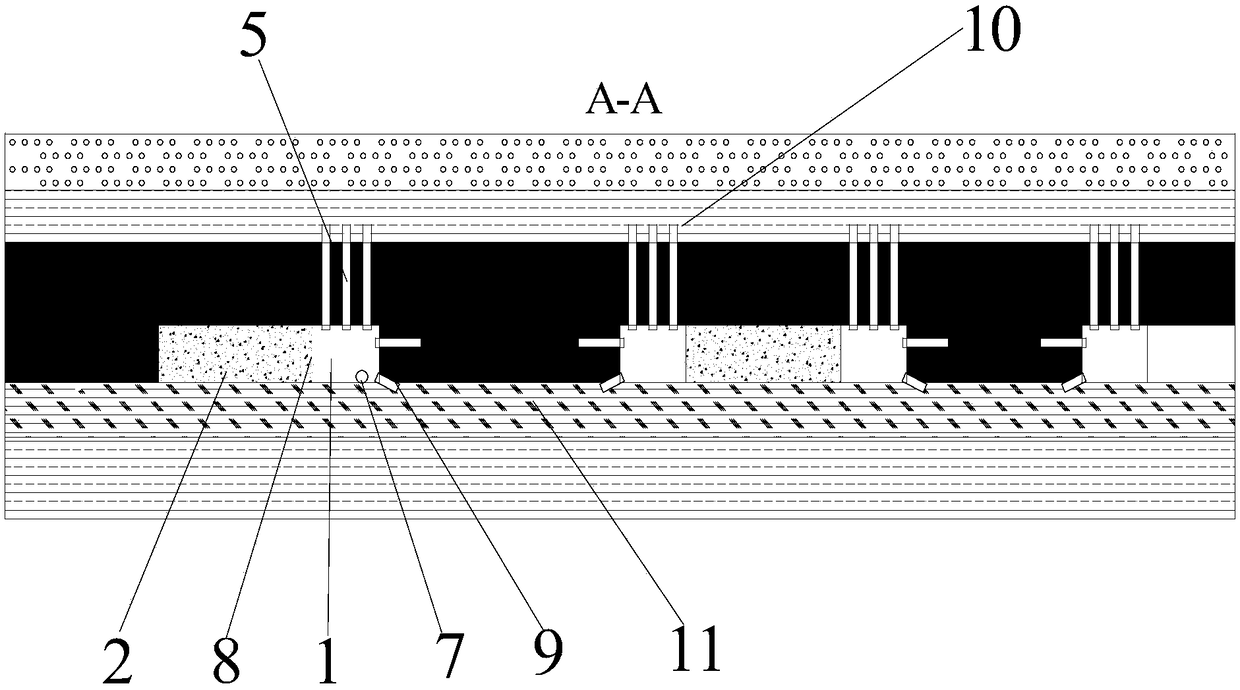

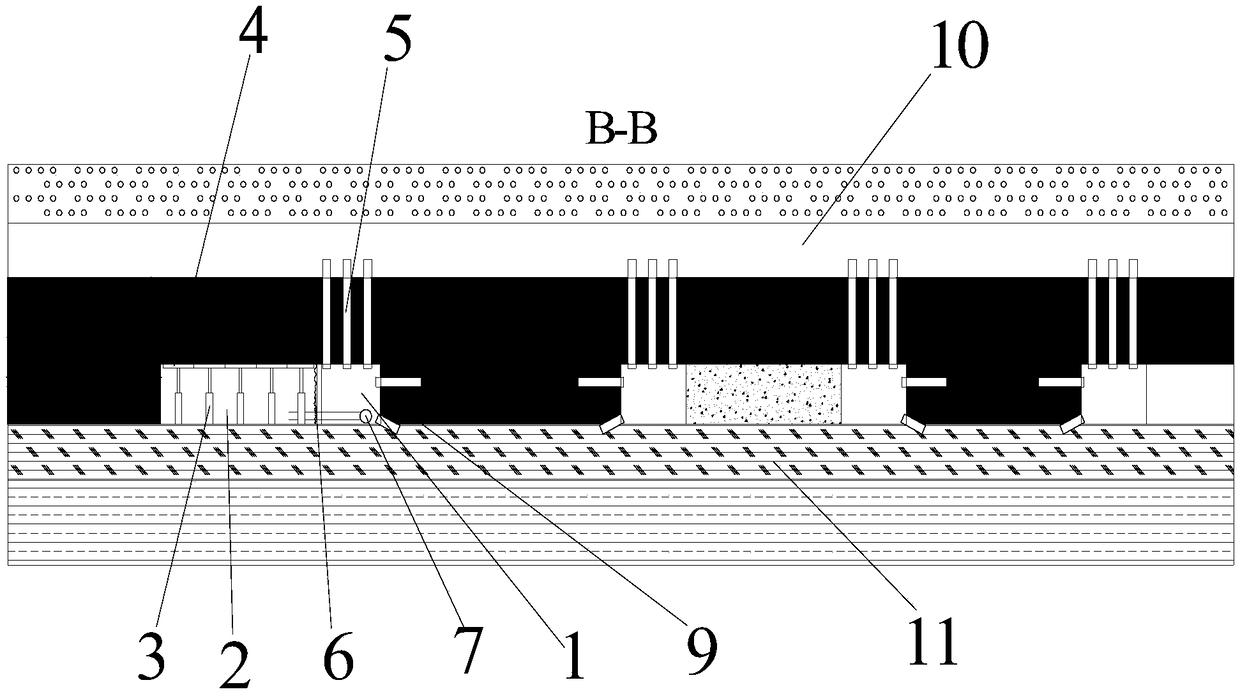

[0034] combine Figure 1 to Figure 4 Shown:

[0035] In the first step, according to the geological conditions of the coal seam, the width of the filling zone 2 is determined to be 9m and the width of the newly excavated roadway 1 is 4m.

[0036] In the second step, combined with the existing technical conditions of mine excavation, the cycle filling step L is determined to be 14m. When the newly dug roadway 1 is excavated in the coal seam, the section size of the roadway is 4m wide and 3m high. Roadway top plate 10, base plate 11, and roadway inner side 9 play strong anchor rods and anchor cables, and hang diamond-shaped metal mesh at the end of the anchor rods to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com