Method for preparing calcium sulfate whiskers and silica sol from low-grade wollastonite

A calcium sulfate whisker, wollastonite technology, applied in chemical instruments and methods, silicon oxide, silicon dioxide, etc., can solve the problems of low added value, underutilization and development of wollastonite, and achieve convenient Large-scale application, expanding application market, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

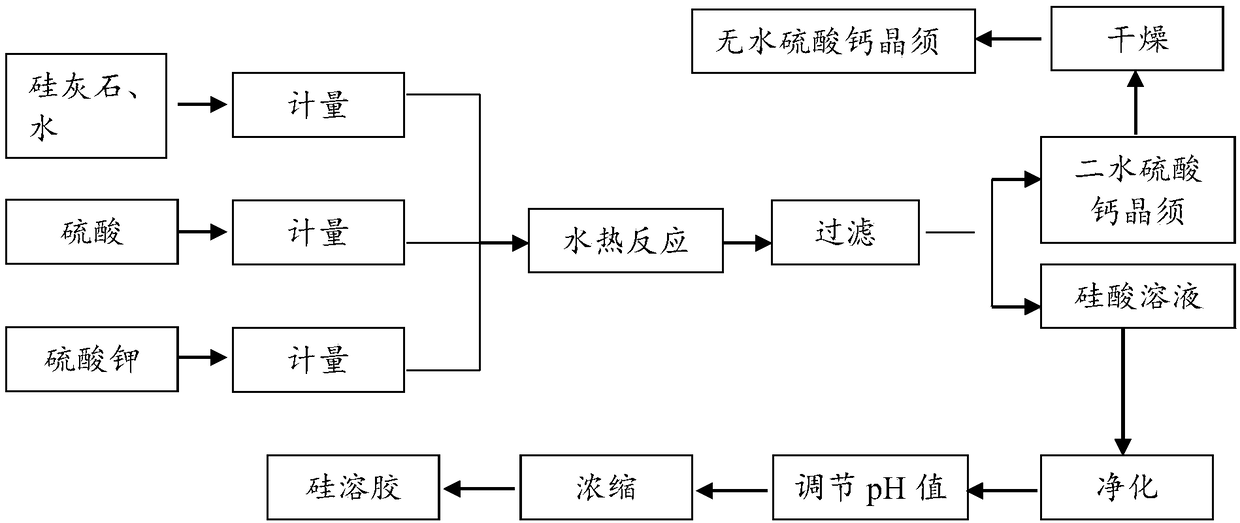

[0021] Example 1, see figure 1 :

[0022] The present invention provides a method for preparing calcium sulfate whiskers and silica sol by using low-grade wollastonite. The Daye wollastonite mine in Hubei with a settlement value of 50 is used. The chemical composition is shown in Table 1. 98wt% industrial sulfuric acid, industrial grade sulfuric acid potassium.

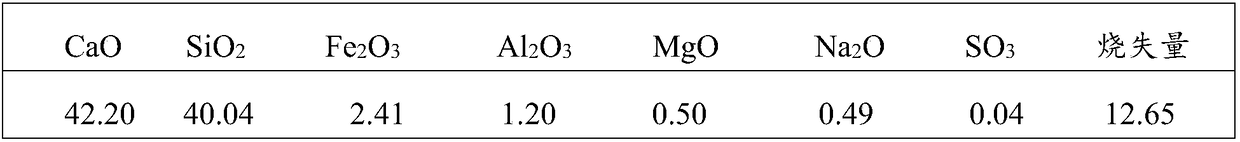

[0023] Table 1 The mass fraction (%) of each component of wollastonite powder in Daye, Hubei

[0024]

[0025] Including the following steps:

[0026] 1) Pulverization: 1 ton of wollastonite ore is crushed into 120 mesh wollastonite powder, and the content of CaO in the wollastonite powder is determined to be 42.2% (corresponding to 0.75 moles);

[0027] 2) Hydrothermal reaction: Add wollastonite powder and 16 tons of water into the reaction kettle, set the reaction temperature to 50°C, turn on the agitator, control the speed at 80 rpm, and add 0.7530 tons of 98wt% industrial Concentrated sulfuric acid, stir ev...

Embodiment 2

[0031] The invention provides a method for preparing calcium sulfate whiskers and silica sol by using low-grade wollastonite, using wollastonite ore produced in Xinjiang with a settlement value of 50 as raw material, wherein the mass percentage of CaO is 46.21%, and the corresponding mole number is calculated is 0.82, including the following steps:

[0032] 1) Pulverization: 1 ton of wollastonite ore is pulverized into 130 mesh wollastonite powder, and the content of CaO in the wollastonite powder is determined to be 46.21%;

[0033] 2) Hydrothermal reaction: Add wollastonite powder and 16 tons of water into the reaction kettle, set the reaction temperature to 50°C, turn on the agitator, control the speed at 80 rpm, and add 0.7530 tons of 98wt% industrial Concentrated sulfuric acid, stir evenly, add 15kg potassium sulfate to react for 75min, stop stirring, adopt centrifugal dehydrator to filter, obtain solid calcium sulfate dihydrate whiskers and liquid silicic acid solution; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com