Energy-saving methane chloride production system and method

A monochloromethane and production method technology, applied in the field of monochloromethane energy-saving production system, can solve the problems of consumption of external cooling capacity and unreasonable use of reaction heat, etc., to reduce recovery costs, save cooling capacity and production and operation costs, The effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

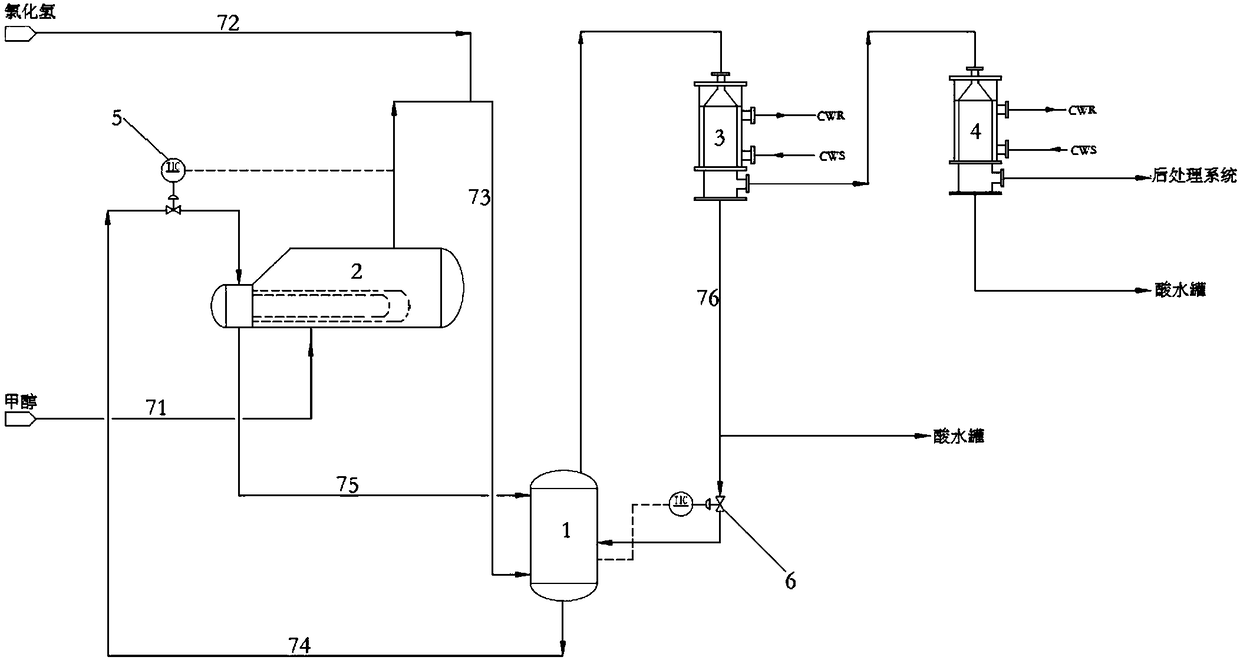

[0041] Such as figure 1 As shown, an energy-saving production system for methyl chloride includes a reactor 1, a methanol vaporizer 2, and a condenser. The methanol vaporizer 2 is used for heating raw methanol, and is connected to the reactor 1 through a pipeline. The system condenser includes a first condenser 3 and a second condenser 4 connected in series for condensing unreacted raw materials in the separated product.

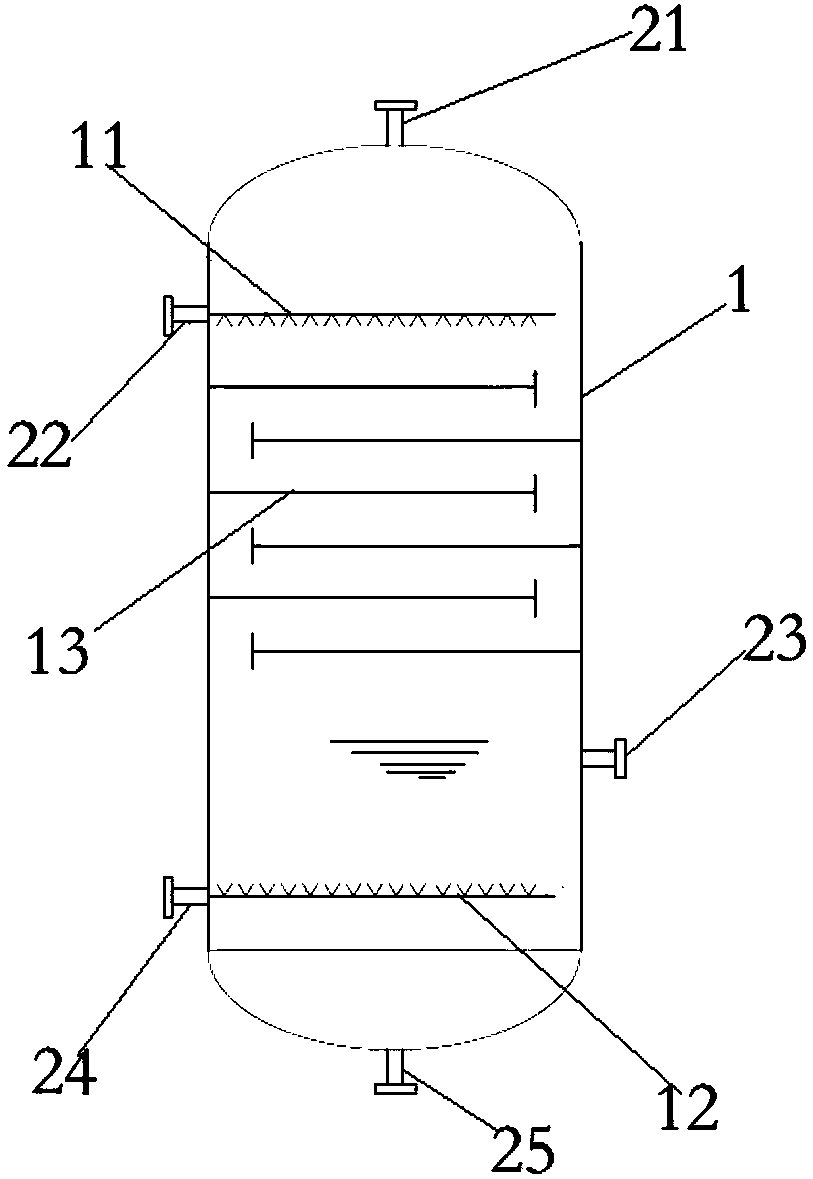

[0042] Such as figure 2 As shown, the top of the reactor 1 is provided with a gas phase outlet 21, the wall of the reactor is sequentially provided with a liquid phase inlet 22, a reflux port 23, and a gas phase inlet 24 from top to bottom, and a liquid phase outlet 25 is provided at the bottom of the pot. The reactor 1 is equipped with a liquid phase distributor 11, a tray gas distributor 12, and a tray 13. The installation position of the liquid phase distributor 11 corresponds to the liquid phase inlet 22, and the position of the gas distributor 12 correspon...

Embodiment 2

[0046] In this embodiment, on the basis of the above-mentioned embodiment, a first temperature regulating valve 5 is installed on the first circulation line 74, and a second temperature regulating valve 6 is installed on the return line 76. The first temperature regulating valve 5 controls the discharge temperature of the methanol vaporizer 2 by adjusting the flow rate of the produced liquid at the bottom of the reactor 1. The second temperature regulating valve 6 controls the reaction temperature in the reactor 1 by adjusting the reflux flow rate of the condensate in the first condenser 3. The temperature automatic control valve can effectively ensure the stability of the process parameters and the stable operation of the reaction.

Embodiment 3

[0048] In this implementation, on the basis of the foregoing embodiment, the number of the trays 13 is 1 to 10, and the design selection is made according to the reaction parameters. The form of the tray 13 may be any of sieve trays, bubble cap trays or valve trays. And the material of the tray 13 can be selected from anti-corrosion materials such as 1Cr18Ni9Ti, 00Cr17Ni 14Mo2, 00Cr18Ni5Mo3Si2, Hastelloy, NI+Q345R, TA+Q345R, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com