Cement-based composite anti-crack binding dry mortar and preparation and application methods thereof

A dry powder mortar, cement-based technology, applied in the field of building materials, can solve the problems of limited application of polyethylene polypropylene fiber composite waterproof system, high shrinkage and easy cracking, low adhesive force of adhesive, etc., and achieves good waterproof and impermeability effect, The effect of less pollutants and industrial waste and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of cement-based composite anti-cracking bonded dry powder mortar comprises the following steps:

[0048] (1) Weigh ordinary Portland cement, quartz sand, anti-crack fiber, cellulose ether, latex powder, and fly ash according to the aforementioned mass ratio;

[0049] (2) Put the weighed raw materials into the mixer for mixing, through sufficient mechanical stirring, after mixing evenly, the product is obtained.

[0050] The method for using the cement-based composite anti-cracking bonded dry powder mortar comprises the following steps:

[0051] (1) Accurately weigh the finished anti-cracking adhesive dry powder mortar of the present invention and the corresponding mass fraction of water, water: anti-cracking adhesive dry powder mortar is (100-200): 1000;

[0052] (2) After adding water to the mixer, turn on the mixer, and add the weighed anti-cracking adhesive dry powder mortar into the mixer at a uniform speed, and it can be used after mixing ev...

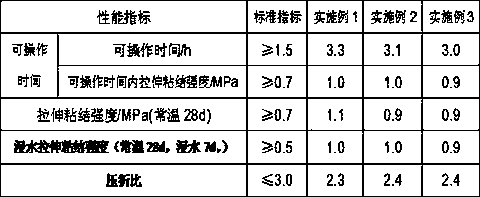

Embodiment 1

[0053] Embodiment 1, a kind of cement-based composite anti-crack bonding dry powder mortar, according to the quality of 42.5 grade ordinary Portland cement 300, quartz sand 642, anti-cracking fiber 0.5, cellulose ether 2.5, latex powder 30, fly ash 25 It is prepared from the ratio, and the amount of water added is 200 parts by mass when used. See Table 1.

Embodiment 2

[0054] Example 2, a cement-based composite anti-cracking bonding dry powder mortar, according to the quality of 42.5 grade ordinary Portland cement 300, quartz sand 649, anti-cracking fiber 0.4, cellulose ether 2.6, latex powder 25, fly ash 23 It is prepared from the ratio, and the amount of water added is 150 parts by mass when used. See Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com