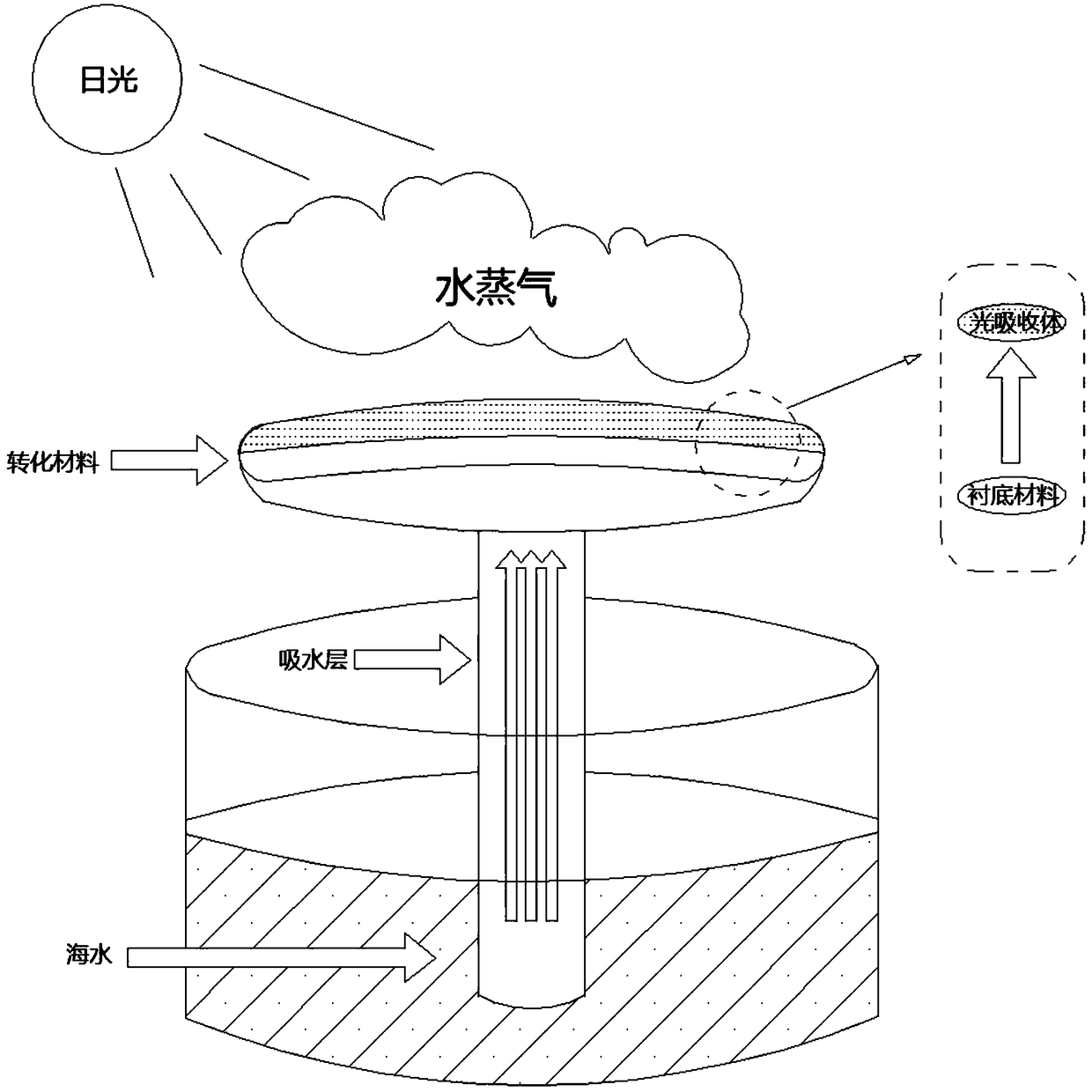

Light-heat-steam conversion material and preparation method thereof

A light-to-heat conversion and steam technology, applied in chemical instruments and methods, general water supply conservation, water/sludge/sewage treatment, etc., can solve problems such as difficult large-scale preparation, high cost, and obstacles to popularization and use, and achieve stability The effect of operation, low cost and high cost performance advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

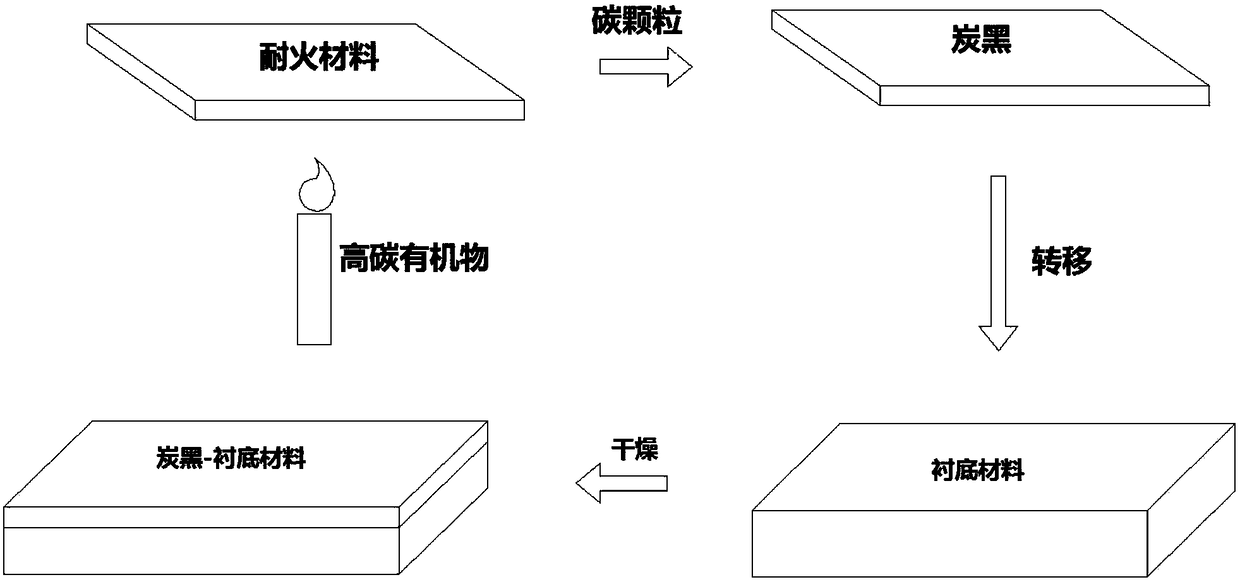

[0043] The preparation method of this embodiment is as figure 2 As shown in the diagram, there are two steps in the illustration, namely the fabrication of carbon black transfer plate and the coupling of carbon black and substrate material PVA. The physical picture of the dry sample before and after coupling is as follows Figure 5 , magnified 2500 times the microstructure such as image 3 , Figure 4 . This embodiment 1 will describe the method of using this invention to prepare high-efficiency solar-driven water evaporation.

[0044] Present embodiment is as substrate material with PVA, and candle provides carbon black particle as high-carbon organic matter combustion, and glass sheet comprises five steps as refractory material: (1) cleaning of substrate material PVA; (2) carbon black transfer plate Production; (3) transfer of carbon black powder; (4) drying; (5) water evaporation test.

[0045] The detailed process of each step is as follows:

[0046] (1) Cleaning of...

Embodiment 2

[0062] The preparation method of this embodiment is as figure 2 As shown in the diagram, there are two steps in the illustration, namely the fabrication of carbon black transfer plate and the coupling of carbon black and substrate material PVA. This embodiment 1 will describe the method of using this invention to prepare high-efficiency solar-driven water evaporation.

[0063] Present embodiment is as substrate material with PVA, and benzene provides carbon black particle as high-carbon organic matter combustion, and glass sheet comprises four steps as refractory material: (1) cleaning of substrate material PVA; (2) carbon black transfer plate Production; (3) transfer of carbon black particles; (4) drying; (5) water evaporation experiment.

[0064] (1) Cleaning of substrate material PVA

[0065] Same as Example 1, since organic impurities usually remain in industrially produced PVA materials, cleaning is required, and the cleaning steps are the same as Example 1.

[0066] ...

Embodiment 3

[0074] Present embodiment uses sponge as substrate material, and ethylene provides carbon black particle as high-carbon organic matter combustion, and ceramic sheet is as refractory material, comprises four steps: (1) cleaning of substrate material sponge; (2) carbon black transfer plate Production; (3) transfer of carbon black particles; (4) drying.

[0075] (1) Cleaning of substrate material sponge

[0076] Sponge is divided into synthetic sponge and natural sponge. If it is synthetic sponge, it is the same as Example 1, because there are usually residual organic impurities in the synthetic sponge material produced in industry; There will be debris such as fine dust remaining; so it needs to be cleaned, and the cleaning steps are the same as in Example 1.

[0077] (2) Fabrication of carbon black transfer plate

[0078] The source of carbon black in this embodiment is the carbon black particles produced when ethylene is incompletely burned. Since ethylene is a gas under no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com