Ultrafast laser micropore machining method and device based on optical coherence tomographic scanning

A technology of optical coherence tomography and microhole processing, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complex process debugging, long cycle, and damage to the opposite wall, and achieve simple processing and short cycle , The effect of uniform shape of the bottom of the hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

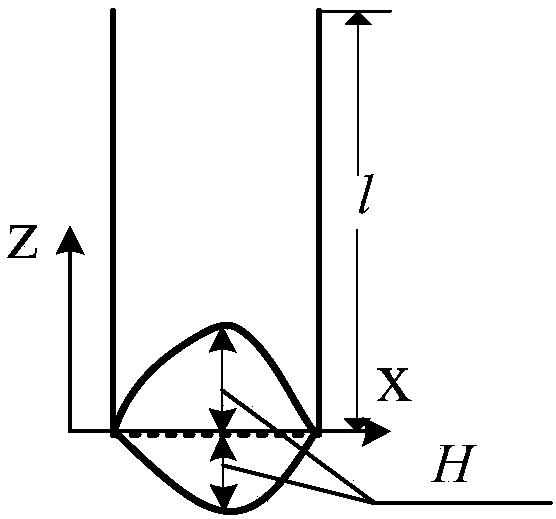

[0046]The present invention adopts optical coherence tomography to coaxially monitor the micropore morphology in the process of processing and real-time control the processing parameters to realize ultra-fast laser microhole processing, which can realize one-stage high-precision microhole processing; firstly, it needs to process the holes according to the workpiece Parameters, determine the initial processing parameters and multiple sets of modified processing parameters; divide the hole-making area into different concentric circles along the radial section of the micro-hole; then start laser scanning to process the micro-hole according to the determined initial processing parameters; In the process of processing, the coaxial monitoring method of optical coherence tomography is used to real-time image the cross-section and depth dimension of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com