Catalyst composition for FT (Fischer-Tropsch) reaction of hydrocarbon and application thereof

A technology for catalyst, torrefaction synthesis, which is used in catalyst activation/preparation, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc., and can solve the problems of inability to adapt to the reaction, low yield of gasoline fractions, and reduced yield of gasoline, etc. Achieve uniform distribution of active components, improve bonding energy and prolong life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Preparation of composite carrier 10g: Add deionized water into the reaction kettle, stir and add attapulgite, stir and mix evenly, and prepare slurry A; use magnesium nitrate and aluminum nitrate as precursors, and use citric acid or ethylene glycol as complex agent, made into a solution and mixed and stirred evenly, then the water evaporated, the solution changed from a transparent sol to a viscous gel, and finally dried at 100-150°C for 1-12 hours, and baked at 200-400°C for 1-4 hours. After roasting, the magnesium aluminum spinel metal oxide MgAl2O4 is obtained; the magnesium aluminum spinel oxide is added to the slurry A, the temperature is controlled, the stirring is continued and the mixing is uniform, and the slurry B is obtained by ultrasonic treatment; the slurry B The attapulgite and spinel oxide composite carrier of the catalyst is obtained by roasting after spray drying and shaping;

[0063] Use equal-volume impregnation method, impregnate and dissolve 0....

Embodiment 2

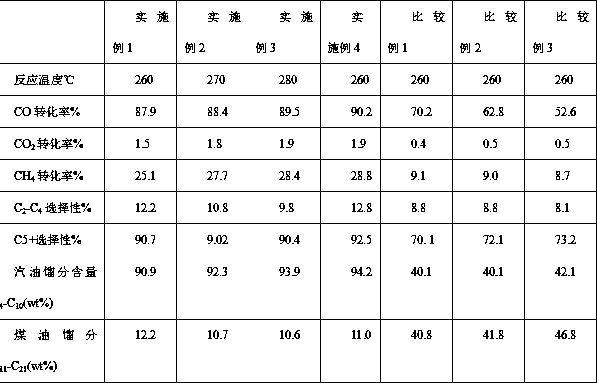

[0069] Active component precursor becomes 0.3g ruthenium chloride and 0.4g cobalt nitrate solution, other conditions are identical with embodiment 1, use catalyst a2, implement under reaction temperature 270 ℃, except that, use the same as embodiment 1 method to react. Table 1 shows the reaction results and the composition analysis results of the products obtained at this time.

Embodiment 3

[0071] The active component precursor becomes ruthenium chloride, cobalt nitrate and ferric chloride solution, using catalyst a3, the Ru:Co:Fe mass ratio of the active metal in catalyst a3 is 1:1-4:1-3, at the reaction temperature The reaction was carried out in the same manner as in Example 1 except that it was implemented at 280°C. Table 1 shows the reaction results and the composition analysis results of the products obtained at this time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com