Liquid urea for vehicles and preparation method thereof

A technology of urea and products for vehicles, which is applied in the chemical industry, can solve the problems of polluted catalysts and high failure rates, and achieve the effects of simple preparation process, strong chelation ability, and improved miscibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

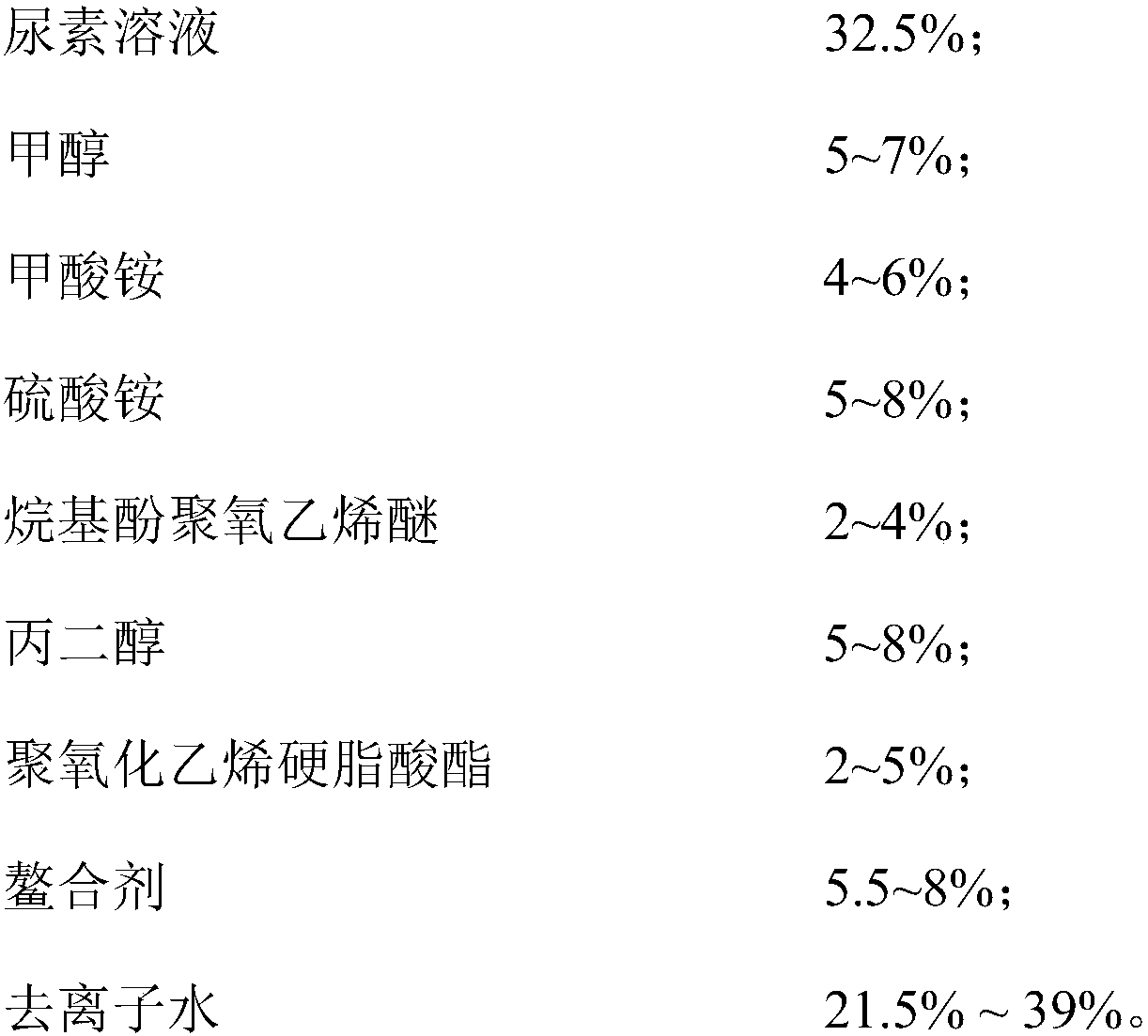

[0022] Embodiment 1: This embodiment provides a kind of urea solution for vehicles, and its components and mass percentages are as follows: 32.5% of urea solution; 5% of methanol; 4% of ammonium formate; 5% of ammonium sulfate; Vinyl ether 2%; Propylene glycol 5%; Polyoxyethylene stearate 2%; Chelating agent 5.5%; Deionized water 39%.

[0023] A kind of preparation method of above-mentioned vehicle urea solution, it comprises the following steps:

[0024] (1) Take deionized water by weight percentage, then pour it into a mixing bucket, and heat it to 70-75°C, and then keep it at a constant temperature;

[0025] (2) Take the urea solution by weight percentage and add it to deionized water, open the stirrer, and stir evenly;

[0026] (3) Take methanol, propylene glycol and polyoxyethylene stearate by weight percentage and add to deionized water, open the stirrer, and stir;

[0027] (4) Take ammonium formate, ammonium sulfate and alkylphenol polyoxyethylene ether by weight perc...

Embodiment 2

[0032] Embodiment 2, a kind of urea solution for vehicles and its preparation method provided by this implementation, it is basically the same as Example 1, the difference is: the components and mass percentages of the urea solution for vehicles are as follows: urea solution 32.5%; methanol 7%; Ammonium formate 6%; Ammonium sulfate 8%; Alkylphenol polyoxyethylene ether 4%; Propylene glycol 8%; Polyoxyethylene stearate 5%; Chelating agent 8%; Deionized water 21.5%.

Embodiment 3

[0033] Example 3, a kind of urea solution for vehicles and its preparation method provided by this implementation, it is basically the same as Example 1, the difference is: 32.5% urea solution; 6% methanol; 5% ammonium formate; 7% ammonium sulfate; 3% phenol polyoxyethylene ether; 6% propylene glycol; 4% polyoxyethylene stearate; 6% chelating agent; 30.5% deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com