A multi-stage air-cooled heat dissipation device

A heat dissipation device and multi-stage wind technology, which is applied in cooling/ventilation/heating transformation, semiconductor/solid-state device parts, semiconductor devices, etc., can solve the problem of single heat dissipation effect, increase enterprise income, improve product yield, The effect of extending the service life cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

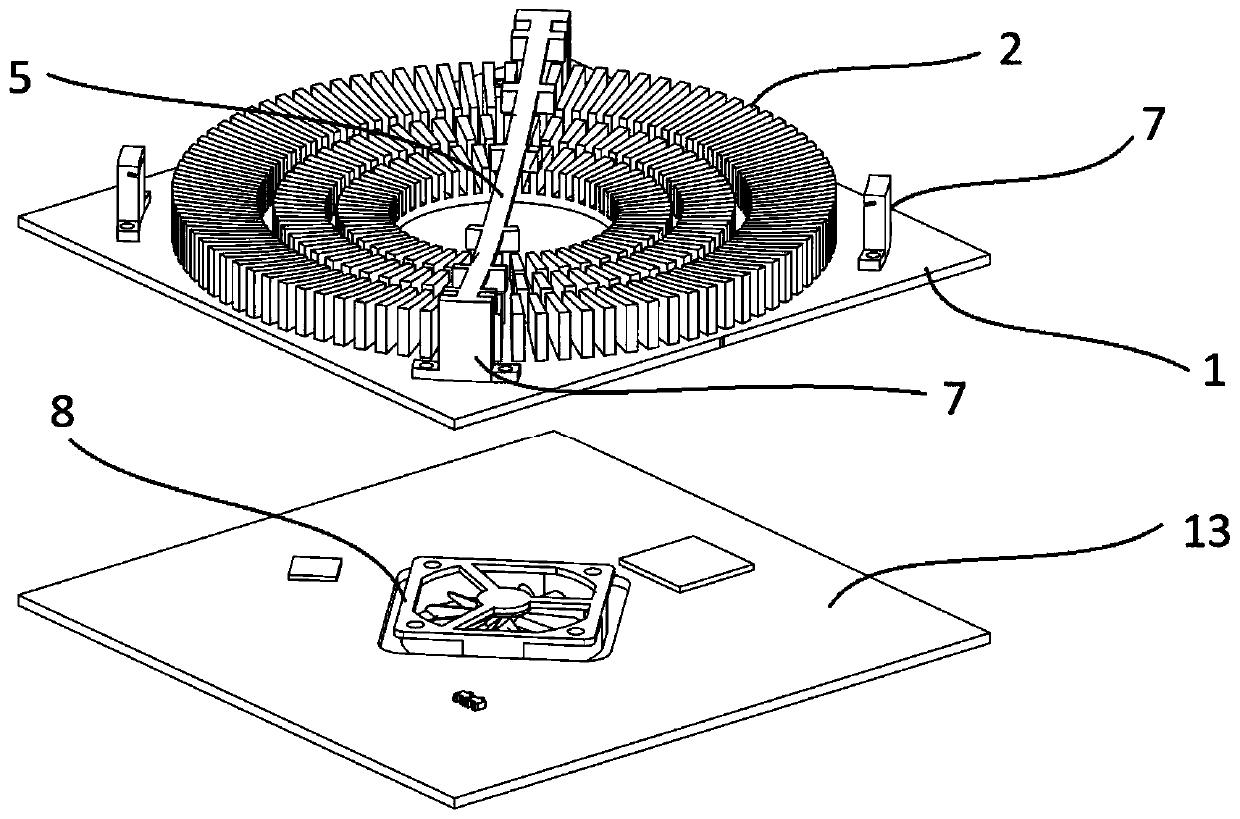

[0045] A multi-stage air-cooled heat sink, such as Figure 1-4 As shown, it is used for the heat dissipation of the PCB board. Specifically, a heat sink 1 is arranged on the PCB board, and the PCB board mainly performs heat dissipation through the heat sink 1. The present invention achieves the heat dissipation of the PCB board by controlling the heat dissipation of the heat sink 1. control.

[0046] Regarding the key components of the present invention, namely the heat sink 1 and other components loaded on the heat sink 1 .

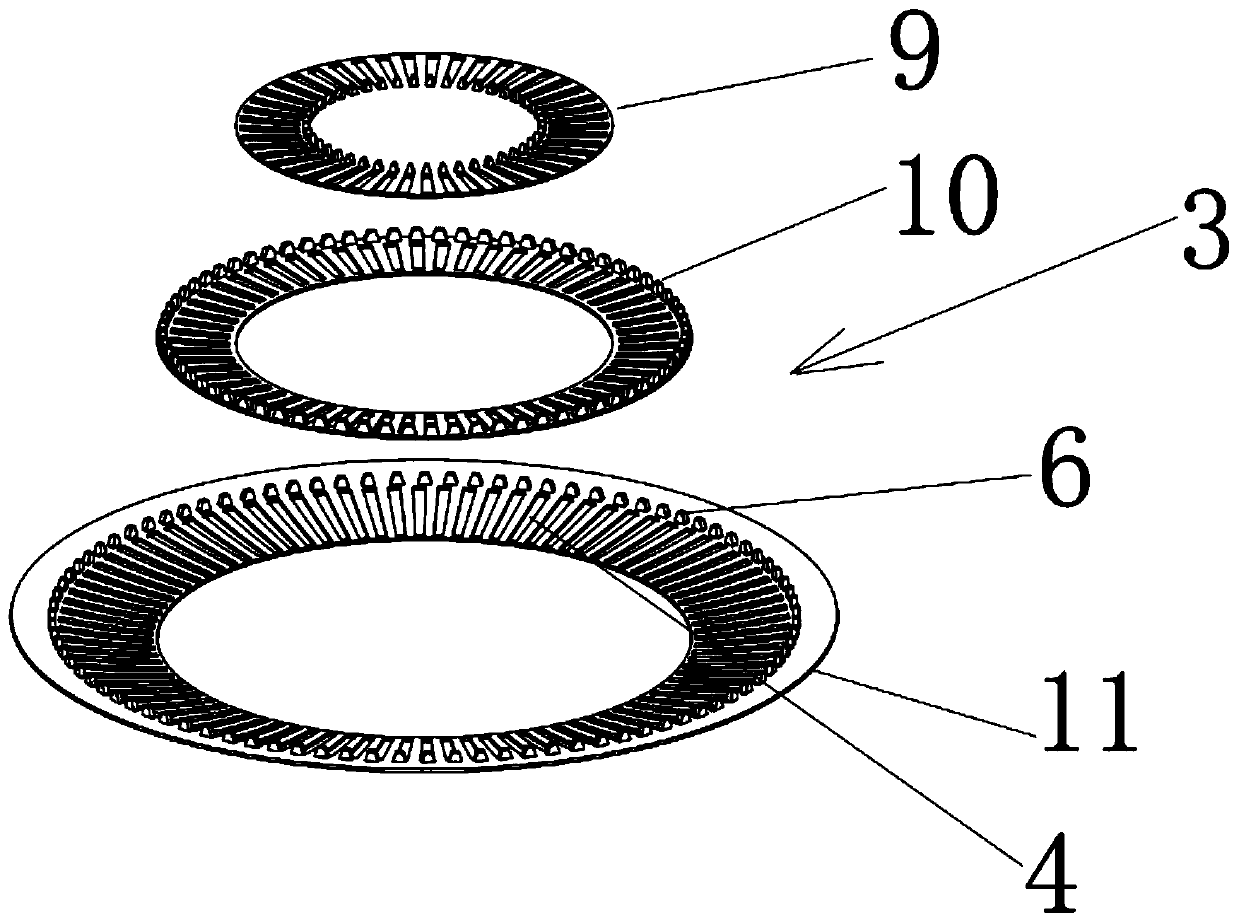

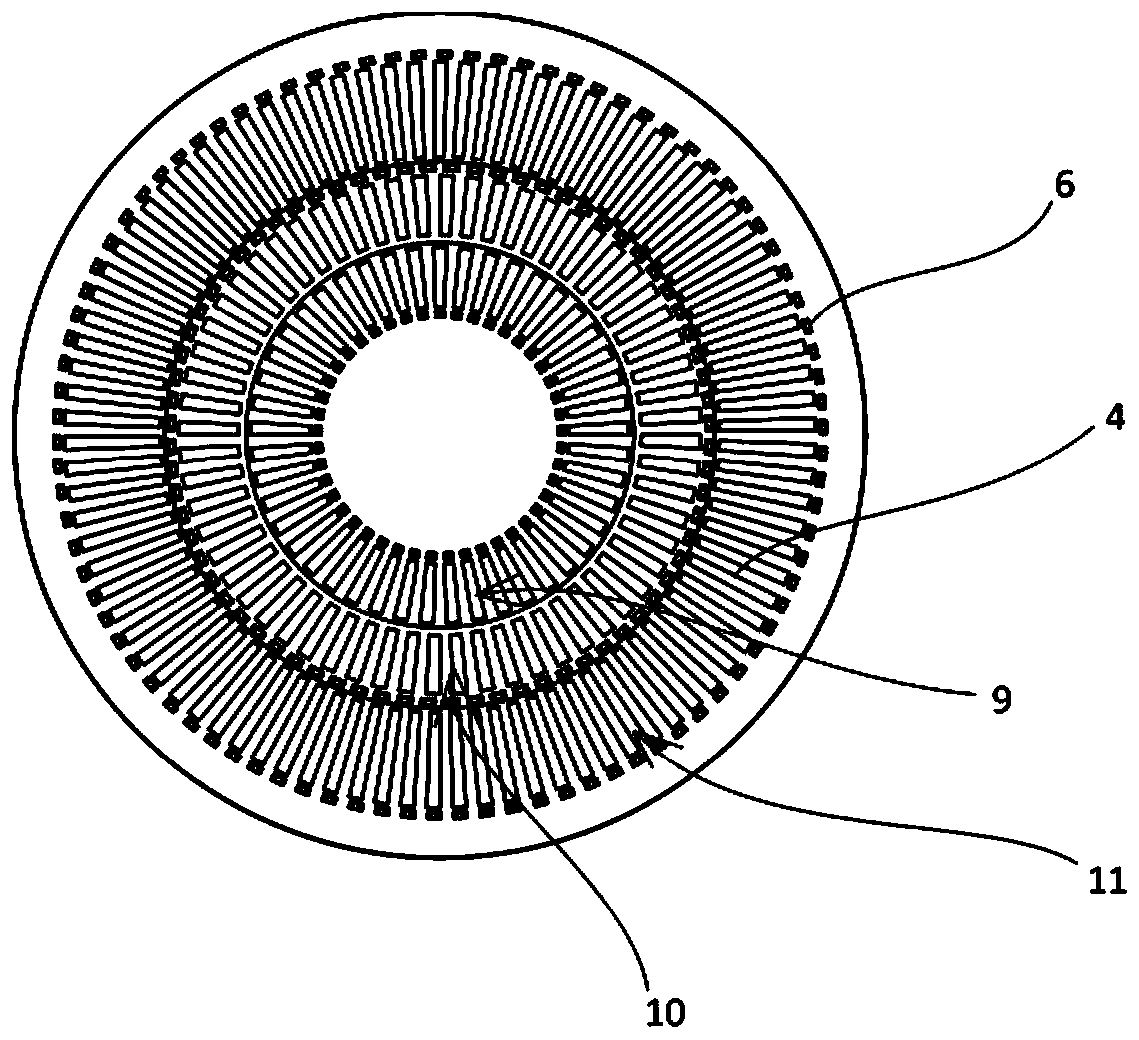

[0047] Specifically, it includes a number of fins 2 arranged on the heat sink 1, and the fins 2 are arranged according to a certain rule. The inner diameters of the arrangement groups formed by the fins 2 are different, forming a multi-layer structure from the inside to the outside.

[0048] The fins 2 arranged in multiple layers form multiple regions to a certain extent, and the boundaries of the regions are formed between layers, and then different hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com