Directional feeding device for different-polarity foot capacitor

An orientation device, capacitor technology, applied in capacitors, capacitor manufacturing, transportation and packaging, etc., can solve the problems of inconvenience, lead wire judgment but container polarity, explosion, etc., and achieve the effect of consistent polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

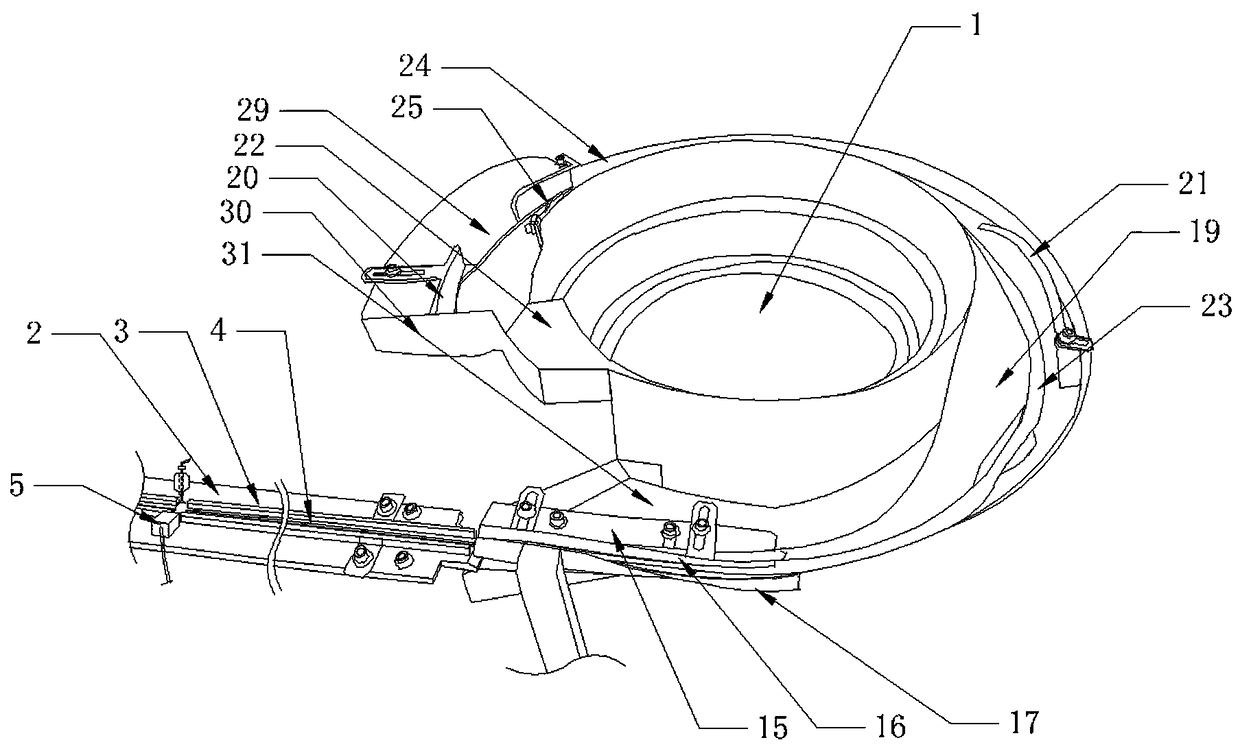

[0032] Such as figure 1 The directional feeding device for heterosexual capacitors shown includes a vibrating plate 1, an alignment device, a positioning device and an orienting device arranged in sequence. Such as Figure 5 As shown, the orientation device includes a base 2 and two first limiting strips 3, and the first limiting strips 3 are relatively fixedly arranged on the base 2 to form the first conveying groove of the capacitor, between the two first limiting strips 3 The base 2 is provided with a first orientation strip 4, and the distance between the two first limiting strips 3 and the first orientation strip 4 is equal; the end of the first limiting strip 3 is provided with a first orientation The neutral gear 32 of bar 4 is fixedly provided with CCD5 on the first spacer bar 3 on this neutral gear 32 side, and the detection head of CCD5 is facing the first conveying groove; A rotating assembly is arranged above the conveying trough, and the intercepting assembly is...

Embodiment 2

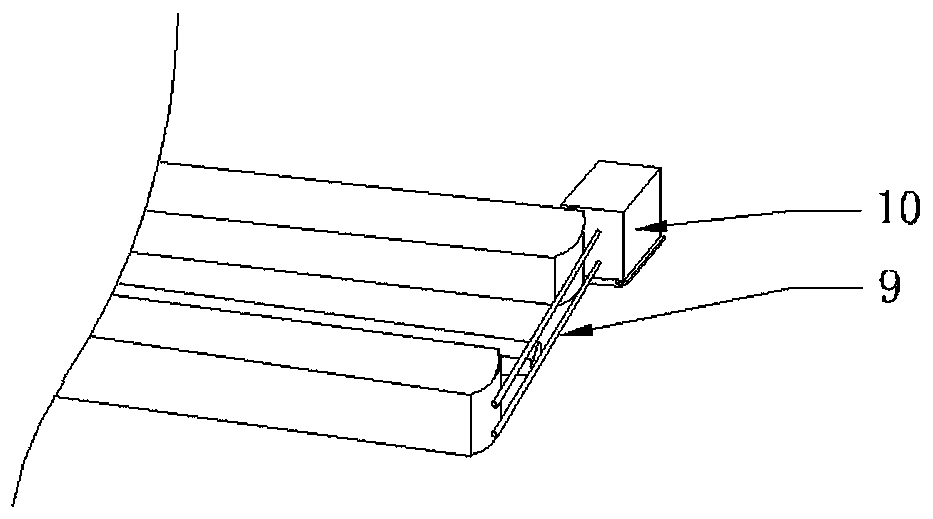

[0042] In this embodiment, the rotating hollow shaft 7 is connected to the transfer manipulator 14 . In this embodiment, for the situation that the horizontal portion of the capacitor lead extends out of the capacitor case, the intercepting device is provided with two intercepting rods 9 on the same horizontal plane, and the distance between the two intercepting rods 9 is greater than the width of the horizontal part of the lead wire. When the capacitor is rotating, the manipulator 14 drives the suction cup 6 to suck up the capacitor (there is a negative pressure in the suction cup at this time), so that the capacitor comes out from the gap between the two intercepting rods 9, and then the rotating assembly rotates 180 degrees and rotates 180 degrees The rear manipulator can directly transport the capacitor to the next process; the manipulator 14 can also put the capacitor back between the two first limiting bars 3 through the suction cup. Under the situation that the manipula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com