Automatic slag removal biomass combustion device as well as combustion engine and combustion method

A combustion device and automatic slag removal technology, applied in the direction of combustion method, combustion air/fuel supply, combustion equipment, etc., can solve the problems of unfavorable popularization and application, burnout of boilers, investment of labor and time, etc., so as to reduce the use and promotion Low cost, extended service life, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

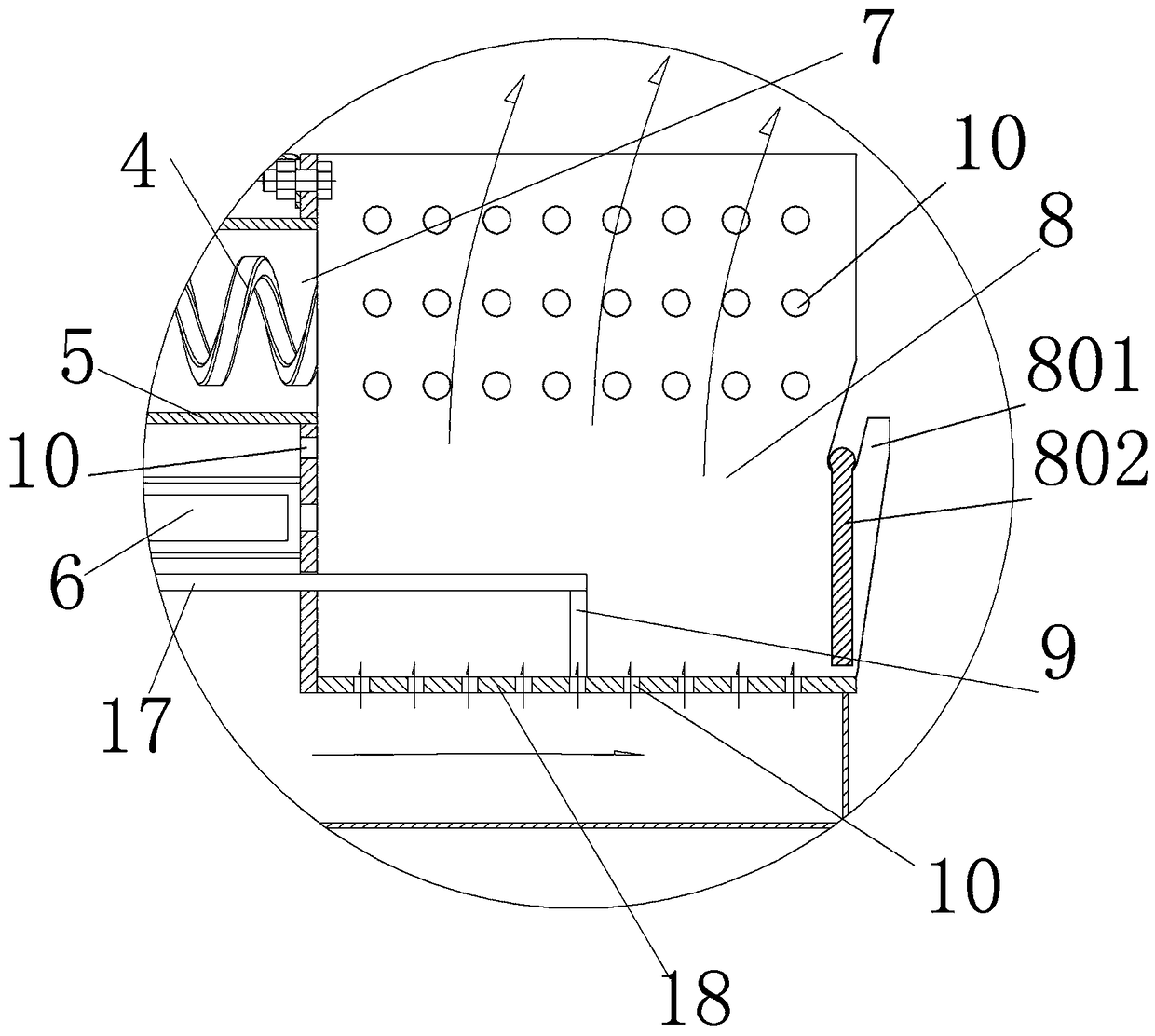

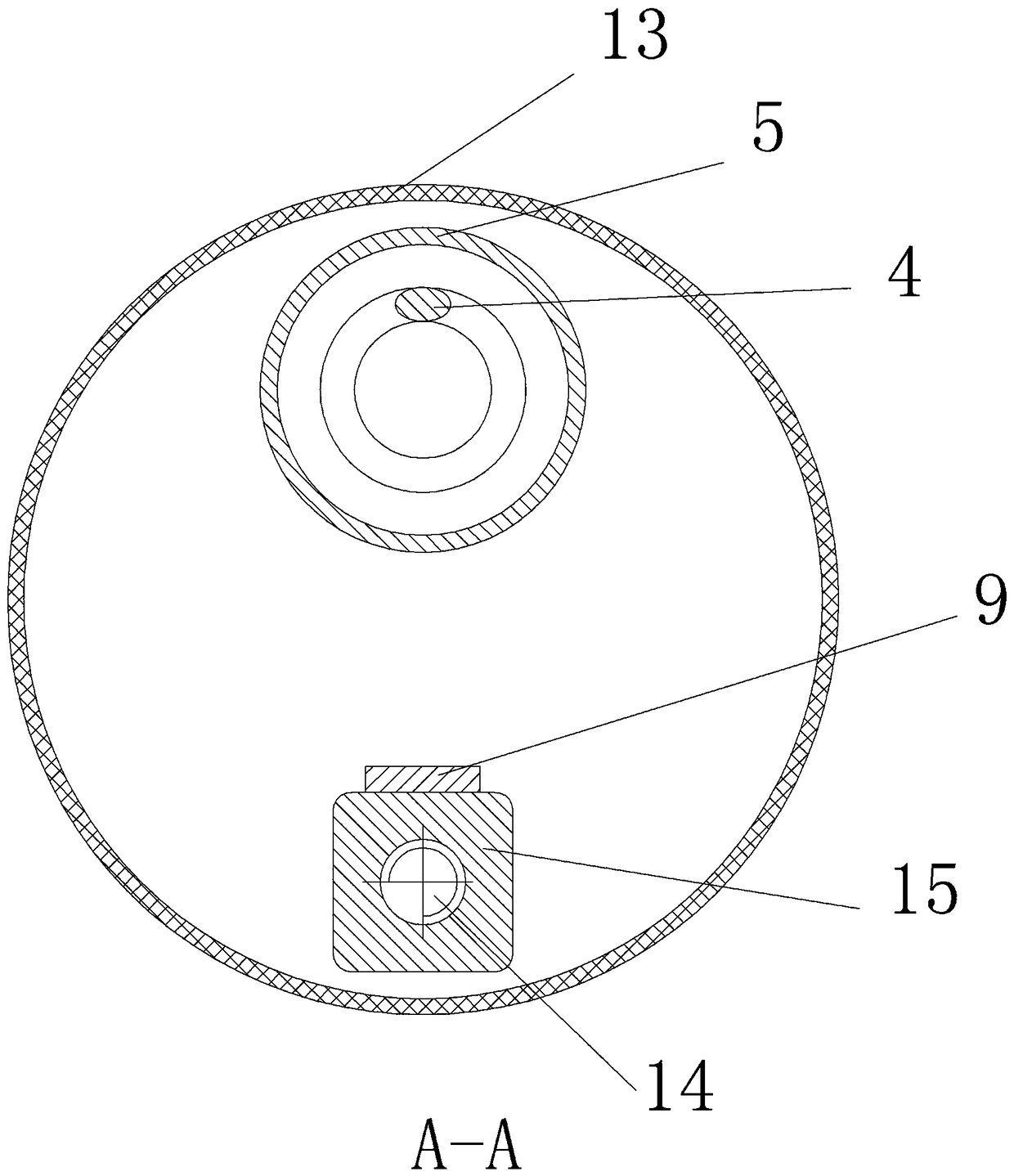

[0035] Embodiment one: see Figure 1-3 , an automatic slag removal biomass combustion device in the figure, the device includes a blower device, a feeding device, a combustion chamber, and a slag removal device,

[0036] The blowing device includes a fan and an air duct; the air duct is a horizontal closed channel, one end is connected to the fan, and the other end is connected to the combustion chamber.

[0037] The combustion chamber includes a material combustion chamber and an air distribution chamber with an L-shaped cross section. The air distribution chamber is located between the material combustion chamber and the air duct. The outer and upper sides of the material combustion chamber are open, and a number of There are several air distribution holes evenly distributed on the rear panel of the combustion chamber and the upper part of the side panels of the combustion chamber, and the air distribution holes are connected to the air distribution chamber and the material ...

Embodiment 2

[0041] Embodiment two, see Figure 1-4 In the figure, a biomass burner comprising the automatic deslagging biomass combustion device described in Embodiment 1, the burner also includes a funnel-shaped silo and a silo frame, and the feeding pipe of the combustion device passes through the fastener and the silo The frame is fixedly connected, the feed bin is located at the upper half of the bin frame, and the lower outlet of the feed bin is connected to the feed port of the feed pipe of the combustion device. In this way, the biomass fuel in the silo can directly enter the feed pipe, and the side of the silo is equipped with a transparent observation hole, which is used to penetrate the amount of biomass fuel in the silo, so that it can be replenished in time; There are universal wheels, which are used as walking wheels when transporting the burner; the feeding pipe of the combustion device is fixed on the warehouse frame through the fixing plate, which is used to install the co...

Embodiment 3

[0043] Embodiment three, see Figure 1-4 In the figure, a method for using the automatic decoking biomass burner described in Embodiment 2 includes the following steps:

[0044] ①. Feeding

[0045] Put the granular biofuel into the silo, and judge whether the fuel is flame-resistant. If it is flame-resistant, hang the baffle at the front of the combustion chamber;

[0046] ②.Feeding and air supply

[0047] Turn on the feeding motor and fan, on the one hand, the biomass fuel is sent to the material combustion bin, and at the same time, the fan disperses the combustion-supporting air into the material combustion bin through the air duct, the air distribution chamber, and the air distribution holes on the lower part and side of the material combustion bin;

[0048] ③. Ignition

[0049] The material falling into the combustion chamber is ignited by the ignition device and starts to burn, and the ignition device goes out when the temperature rises to the set value; the burner bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com