A sandwich metal sheet

A metal sheet and sandwich technology, applied in the field of composite materials, can solve the problems of not pointing out the formation of through air passages, uneven heating, and no heating, so as to improve the brazing efficiency, the welding effect and the brazing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

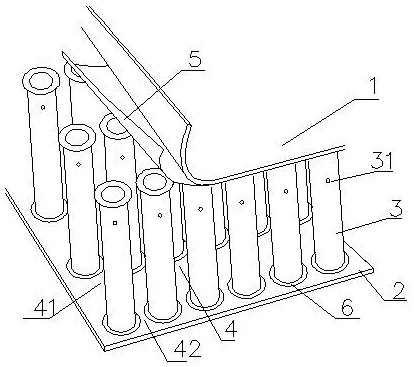

[0031] Such as figure 1Shown: a sandwich metal sheet, including an upper panel 1, a lower panel 2, and several core tubes 3 between the upper panel 1 and the lower panel 2; a plurality of core tubes 3 are provided with through air passages 4, Between the core tube 3 and the upper panel 1 and the lower panel 2, high-temperature gas is used to flow back and forth and left and right through the air channel 4 to realize brazing.

[0032] Specifically, the core tube 3 is a round tube, and the number of core tubes can be selected according to needs. Adjacent core tubes 3 are arranged at intervals to form transverse air passages 41 and longitudinal air passages 42, wherein the row spacing between the core tubes 3 is 40 mm, and the column spacing is 70 mm. The high-temperature gas enters the inner cavity of the sandwich metal plate through the transverse air channel 41 and the longitudinal air channel 42 . Wherein, the core tube 3, the upper panel 1, and the lower panel 2 are brazed...

Embodiment 2

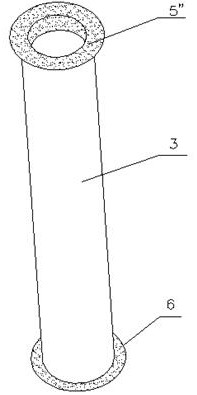

[0037] Such as figure 2 Shown: the difference with embodiment 1 is that the upper and lower ends of the core tube 3 are punched and flanged 6; The material is copper solder 5", and the copper solder 5" is set between the flange 6 of the core tube 3 and the upper and lower panels in the form of a foil sleeve, that is, the copper solder 5" wraps the flange of the core tube 3 6, and extend into the core tube 3, so that the core tube 3 is covered, so that the core tube 3 can be firmly positioned between the panels.

[0038] Others are with embodiment 1.

Embodiment 3

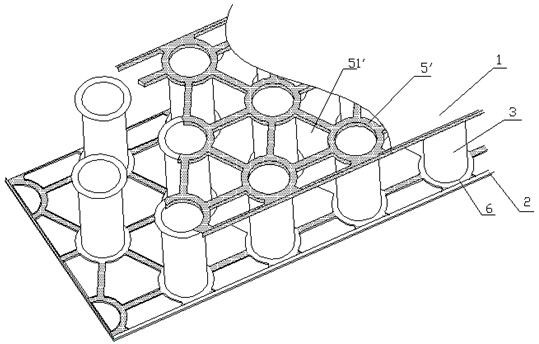

[0040] Such as image 3 Shown: The difference from Example 2 is that the copper solder 5' is arranged between the flange 6 of the core tube 3 and the upper panel 1 and the lower panel 2 in the form of a foil sleeve, and the copper solder 5' is not covered The position of the core tube is provided with a hollow 51 ′, such as a triangular hollow, which can prevent excess copper solder 5 ′ from accumulating during the brazing process and greatly improve the brazing quality.

[0041] Others are with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com