Locking self-sealing dry quick joint

A dry and fast technology, used in mechanical equipment, couplings, etc., can solve the problems of increasing the number of equipment and equipment costs, unfavorable environmental protection and saving, increasing the amount of medium leakage, etc., to avoid accidental medium leakage, save time and Cost, effect of reducing internal friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

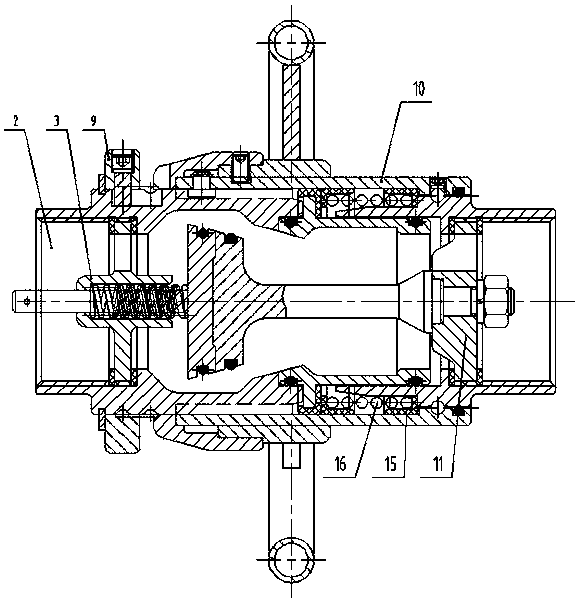

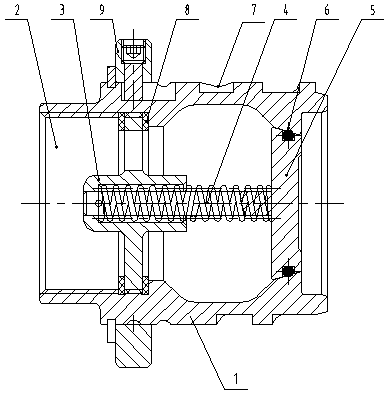

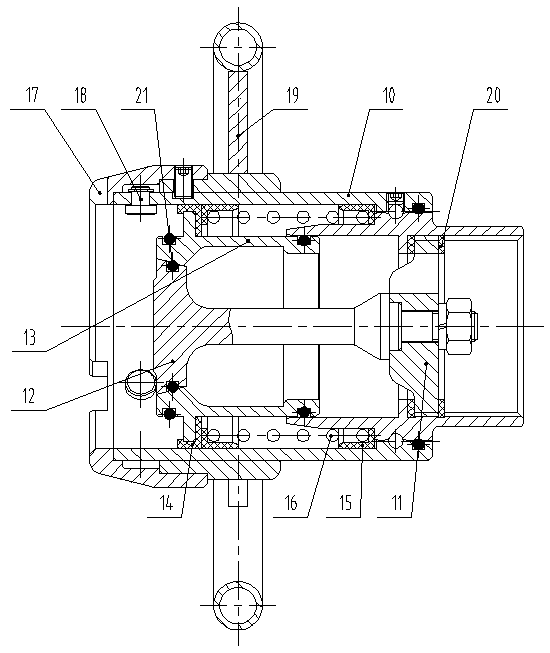

[0024] Such as figure 1 , figure 2 and image 3 As shown, a locking type self-sealing dry quick connector includes a dry quick male connector and a dry quick female connector; the dry quick male connector includes a male connector housing 1, a male connector valve seat 2, a guide spring lining Sleeve 3, spring 4, sliding valve core 5, first O-ring 6, spiral guide groove 7 and first sealing gasket 8; one end of the male connector housing 1 is provided with a male connector valve seat 2, and the male connector housing 1 and the male joint valve seat 2 is provided with a first gasket 8, the male joint valve seat 2 is provided with a guide spring bush 3, the guide spring bush 3 is fixedly connected with one end of the spring 4, and the other end of the spring 4 It is fixedly connected with the sliding valve core 5, and the first O-ring 6 is arranged between the sliding valve core 5 and the male joint housing 1; the outer surface of the other end of the male joint housing 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com