High-pressure-resistant self-sealing main throttle valve

A main valve, self-sealing technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of reducing the efficiency and safety of the unit, waste of resources, etc., to improve the efficiency and operation safety, reduce the main steam The effect of door steam leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

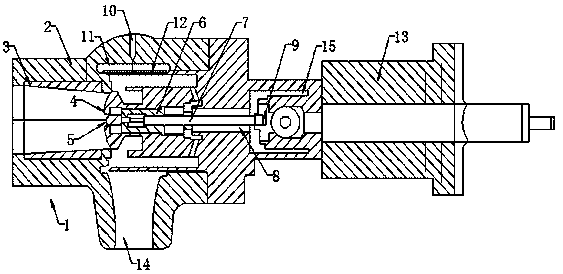

[0015] like figure 1 As shown, the present invention provides a technical solution: a high-pressure self-sealing main valve, comprising a main valve body 1, a valve housing 2 is provided on the main valve body 1, and one side of the valve housing 2 is There is a main valve seat 3 inside, a main valve disc 4 is installed in the main valve seat 3, a pilot valve 5 is installed in the middle of one end of the main valve disc 4, and a pilot valve bushing 6 is installed on the outer side of one end of the pilot valve 5 A main valve stem 7 is installed inside the other end of the pilot valve bushing 6 , a valve core 9 and a pilot valve disc 15 are installed at one end of the main valve stem 7 , and the valve core 9 is located inside the pilot valve disc 15 , a sealing ring 8 is installed on the outer side of one end of the main valve stem 7 through a chuck, one end of the sealing ring 8 is connected with the side end of the pilot valve disc 15, and the oil motor 13 is connected on on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com