A method of converting gently inclined orebody from open-pit to underground mining based on Gebion artificial pillar

A technology of open-pit to underground and artificial pillars, which is applied in open-pit mining, mining equipment, special mining, etc. It can solve problems such as easy safety problems, high cost of artificial pillars, and large loss of ore bodies, and achieve the production process And the effect of simple mining process, improved mechanized operation level, and less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

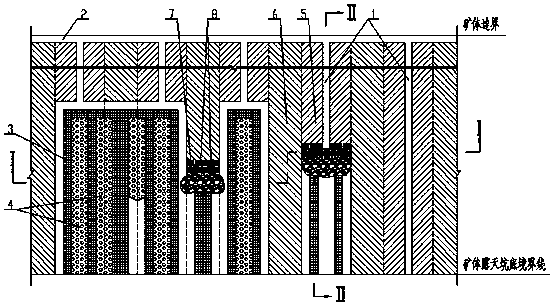

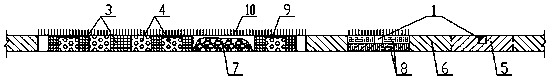

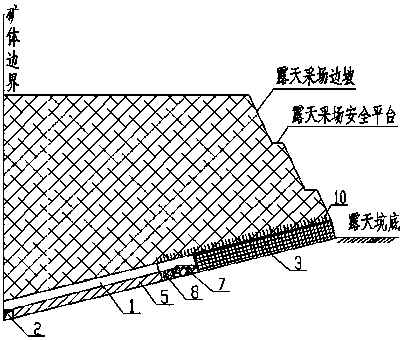

[0030] refer to figure 1 , figure 2 with image 3 , a method of converting gently inclined orebody from open-pit to underground mining based on Gebion artificial pillar, the specific steps are as follows:

[0031] (1) Divide the ore block along the ore body trend 50m wide and 100m long along the ore body inclination, among which the mine house 5 is 30m wide and the ore pillar 6 is 20m wide; in the middle of the mine house 5 axis along the dip angle of the ore body, the quasi-inclined roadway is excavated in the vein 1. It connects with the drainage and air return roadway 2 to form a stope ventilation and drainage channel;

[0032] (2) Mine room 5 and ore pillar 6 are mined alternately, starting from the outcrop of the ore body at the bottom of the open pit, using the free face and the quasi-inclined roadway 1 in the vein as the free face forward min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com