Double-steel-plate reinforced concrete composite beam

A technology of reinforced concrete and composite beams, which is applied in the field of composite beams, and can solve problems such as easy web sag, difficult fabrication, and weak rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

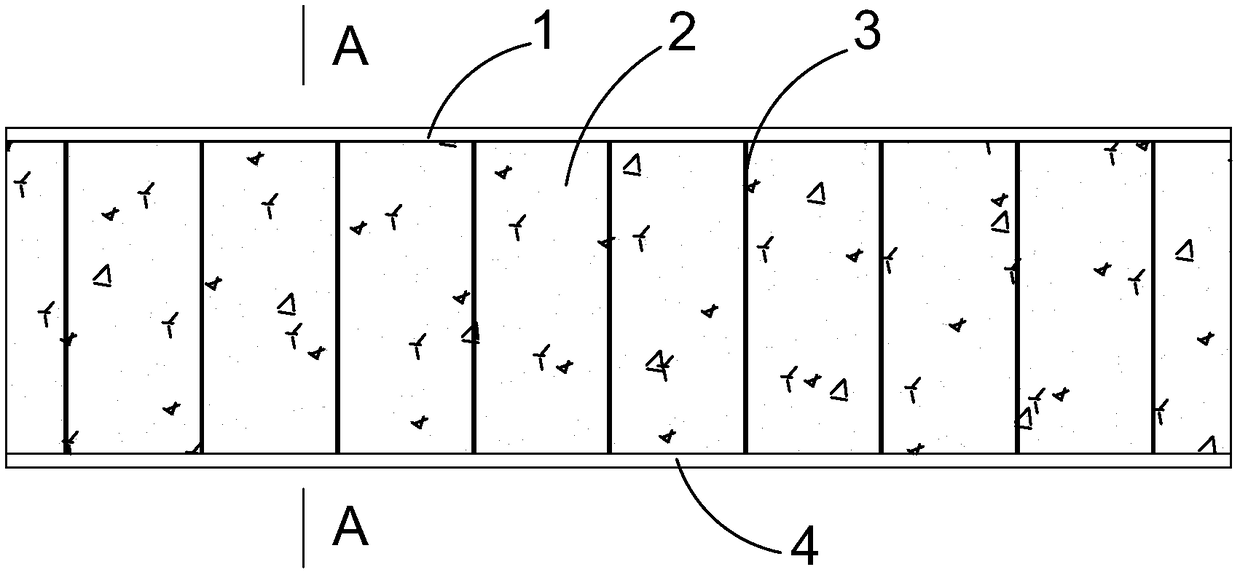

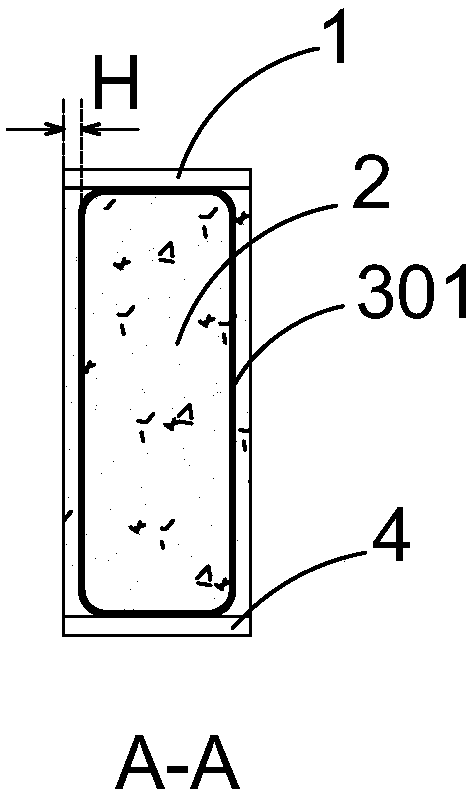

[0012] A double-steel reinforced concrete composite beam, see figure 1 , 2 , be provided with upper steel plate 1 and lower steel plate 4, be welded with stirrup 301 between upper steel plate 1 and lower steel plate 4, the vertical part of stirrup 301 is perpendicular to upper steel plate 1 and lower steel plate 4, the vertical part of stirrup 301 The outer edge is moved inward by a distance H relative to the line between the side edges of the upper steel plate 1 and the lower steel plate 4, the stirrups 301 are evenly spaced along the length direction of the upper and lower steel plates, and concrete 2 is arranged between the upper steel plate 1 and the lower steel plate 4, so that The stirrup 301 is embedded in the concrete 2 .

[0013] Concrete 2 can be poured together with the upper and lower steel plates at the construction site, or can be poured together with the upper and lower steel plates at the factory to form a whole and transported to the construction site.

[00...

example 2

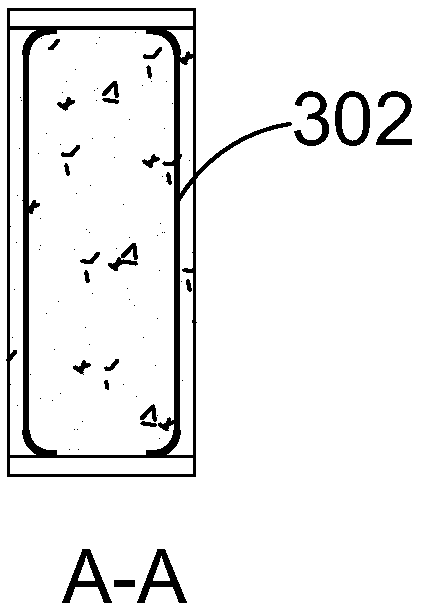

[0022] In this example, double steel plate reinforced concrete composite beam, see figure 1 , 3 , The difference from the above example is that the stirrups 301 are replaced by pairs of symmetrically arranged arcuate ribs 302, and the other structures are the same as the above example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com