Efficient molten iron desulphurization spray gun

A high-efficiency technology for desulfurization of molten iron, which is applied to the field of desulfurization outside the furnace by injecting granular magnesium, and the field of high-efficiency molten iron desulfurization spray guns. Contact time, the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

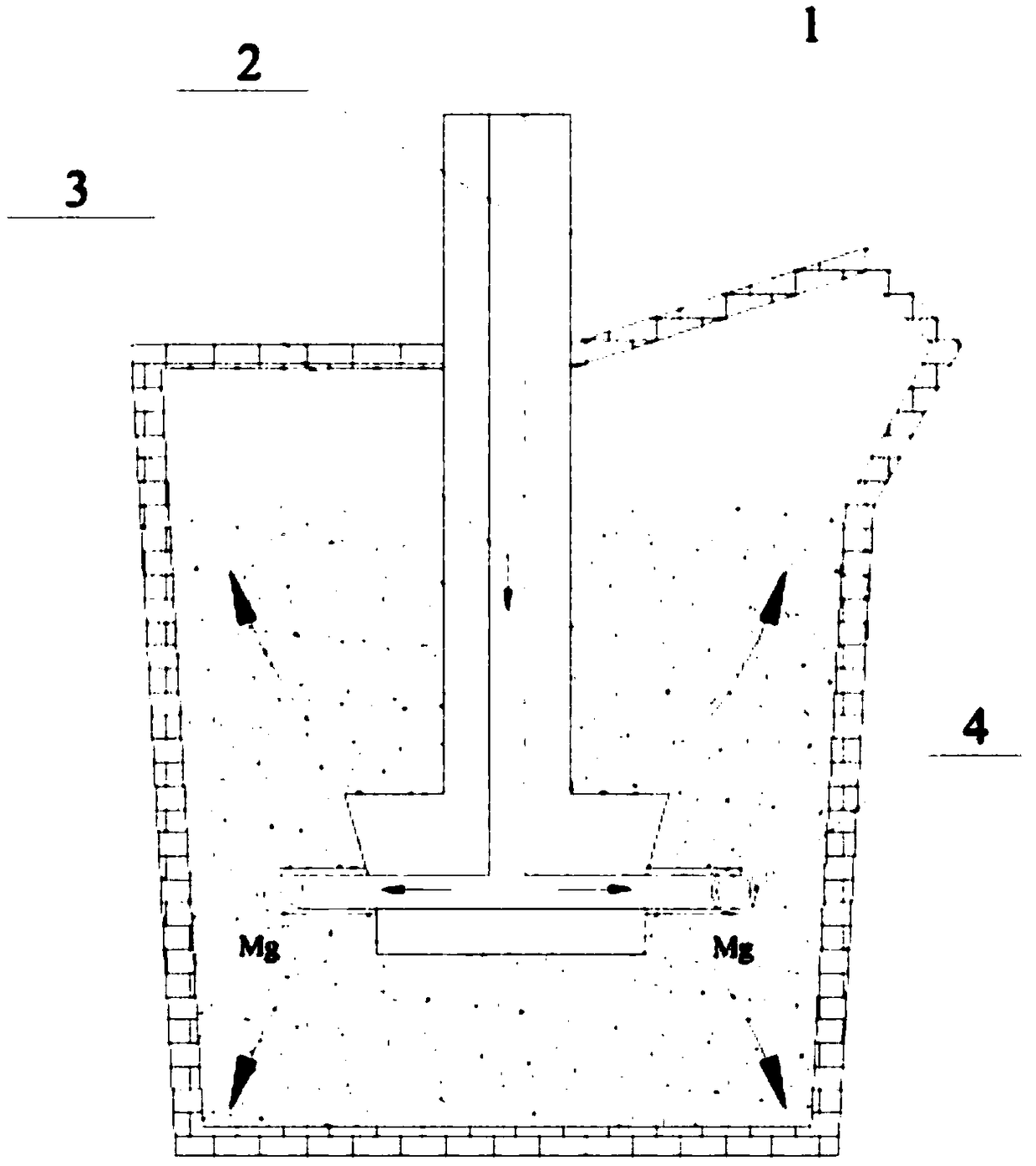

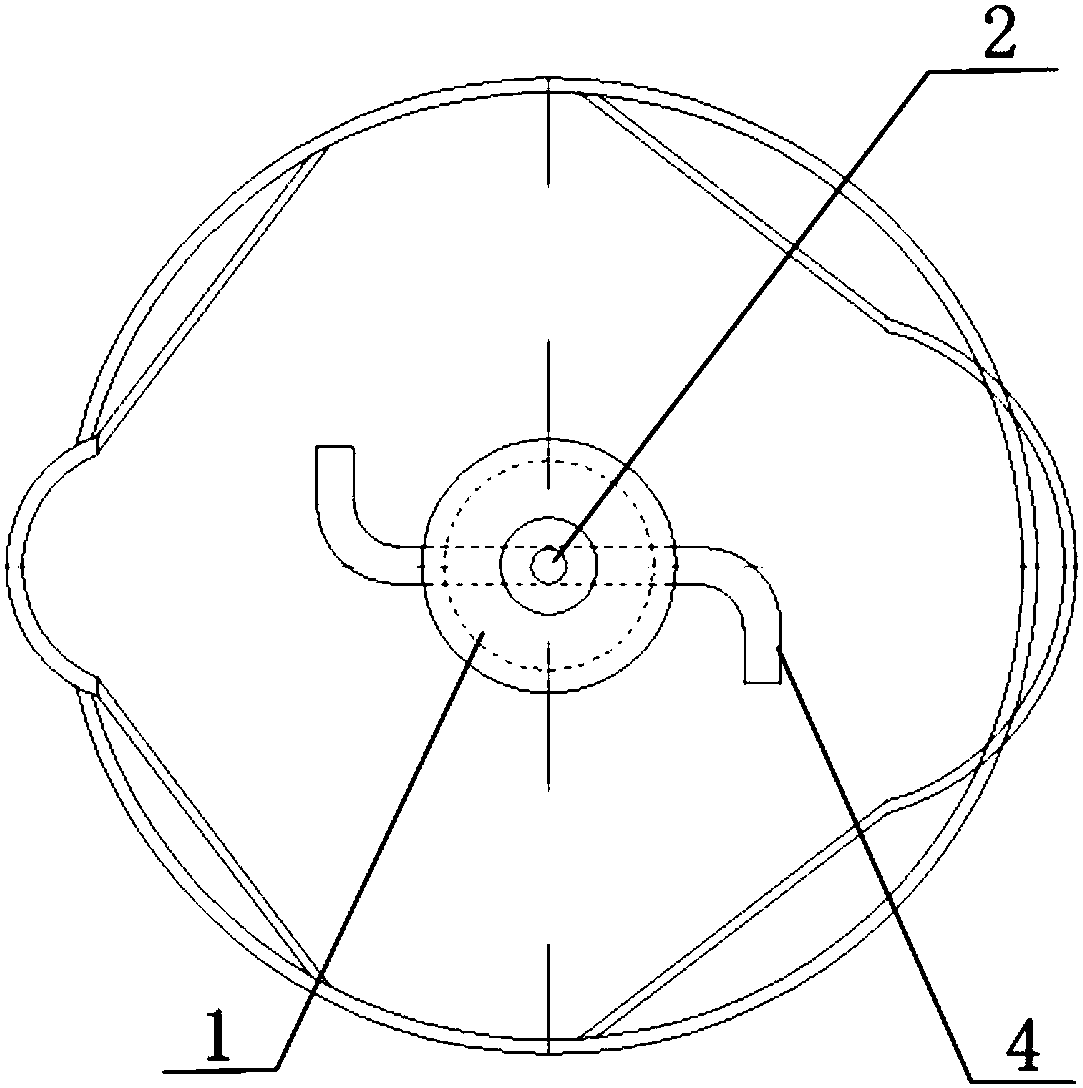

[0041] As another preferred embodiment of the present invention, the high-efficiency molten iron desulfurization spray gun includes a pipe 2 and a number of nozzles 4, wherein the pipe 2 is a straight pipe (that is, only one outlet) set upright, and the immersion end or outlet passes through a multi-way connector They are respectively connected with a plurality of nozzles 4, and the nozzles 4 are arc-shaped tubes arranged horizontally.

[0042] Preferably, the nozzle 4 is an arc-shaped tube, and 2-4 nozzles 4 are used. In order to effectively diffuse the magnesium vapor into the molten iron, more preferably, the vertical distance between the outlet end of the nozzle 4 and the center line of the duct 2 is molten iron The bag cross-sectional radius is 1 / 3-1 / 2, and the central angle is 15°-20° (such as 16°, 17°, 18°, 19°).

[0043] In the preferred embodiment of the present invention, the nozzle 4 is a circular arc tube, preferably three nozzles 4 are used, the vertical distance betwe...

Embodiment 1

[0051] The high-efficiency molten iron desulfurization spray gun used in a factory includes a pipe 2 and a nozzle 4. The shape of the pipe 2 is a double-hole inverted T-shape, and the two outlets of the immersion end are respectively connected with two nozzles 4, see figure 2 , The nozzle 4 is a circular arc tube, the center line of the nozzle 4 is 2 / 3 of the ladle cross-sectional radius from the inner wall of the molten iron ladle, the central angle is 18°, the inner diameter of the nozzle 4 is 7mm, and the inner diameter of the conduit 2 is 16mm.

[0052] When working, insert the high-efficiency molten iron desulfurization spray gun to the designated 2.7m below the molten iron level, the distance between the nozzle 4 and the bottom surface of the desulfurization molten iron ladle is 0.25m, and start spraying. The spraying process parameters are as follows:

[0053] The nitrogen flow rate of the spray gun submerged into the molten iron is 120~140Nm 3 / h, pressure 0.75~0.86Mpa;

[00...

Embodiment 2

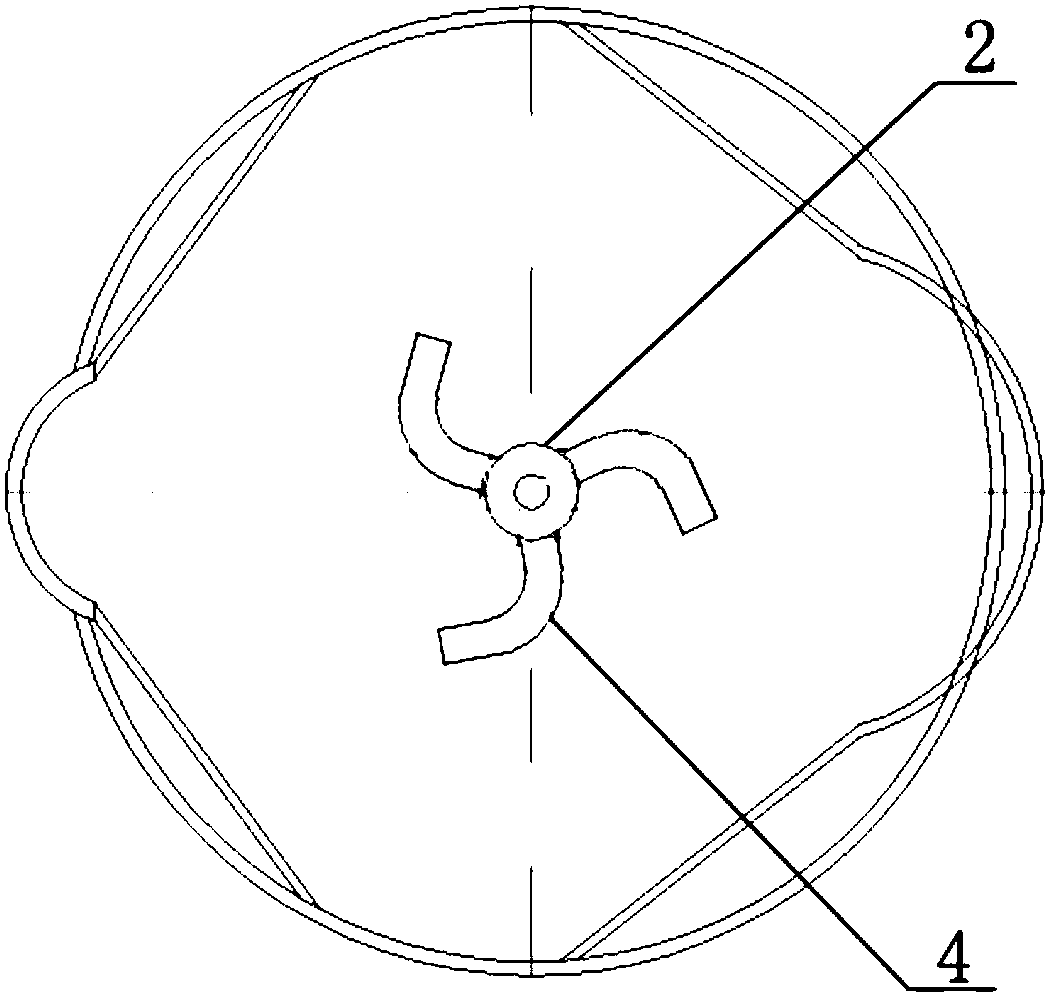

[0060] Except adopt image 3 Except for the spray gun of the structure shown, other injection process parameters are the same as in Example 1. The desulfurization effect of this embodiment is as follows: [S] in the molten iron is removed from 0.030% to 0.050% to less than 0.005%, and even reaches 0.001 to 0.002 %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com