Composite snow melting agent and preparation method thereof

The technology of snow melting agent and compound salt is applied in the field of compound snow melting agent and its preparation, which can solve the problems of ice and snow consolidation, corrosion of metals, and difficulty in removal, and achieve the effect of simple and feasible production process and reduction of metal corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

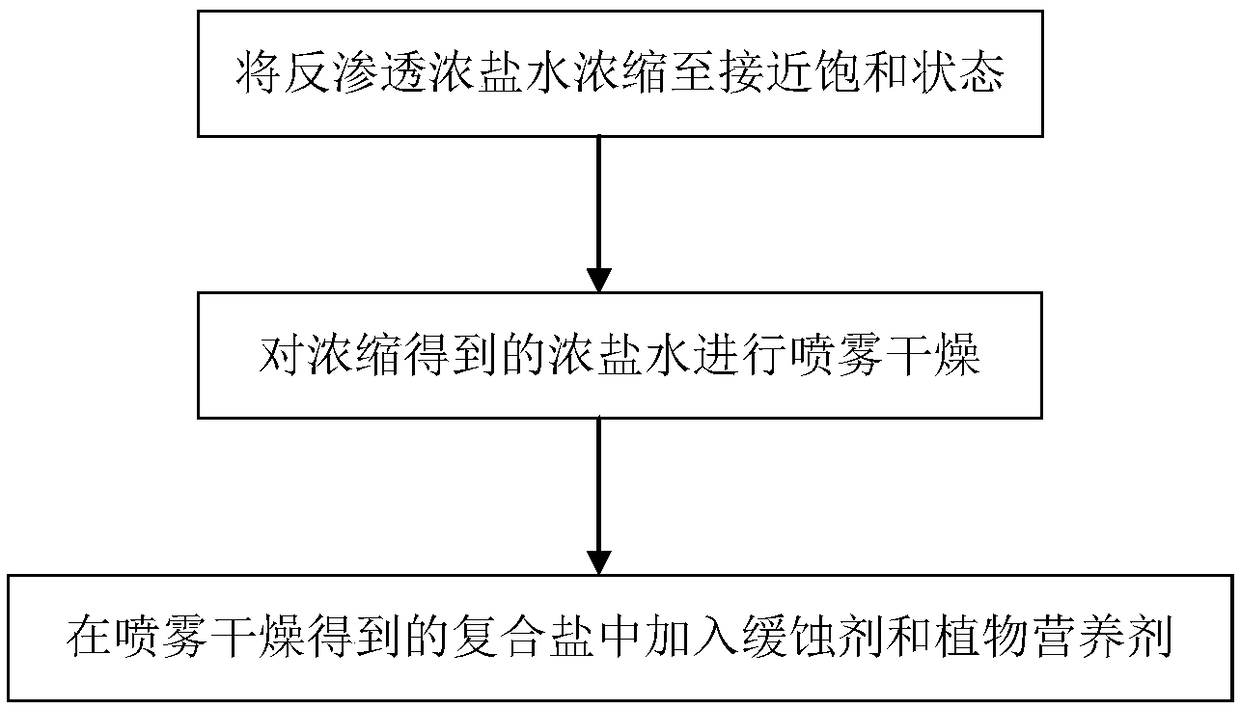

[0020] In the present invention, reverse osmosis concentrated brine is prepared into composite deicing agent, and the preparation method flow chart is as follows figure 1 As shown, the details are as follows:

[0021] 1. Concentrate the concentrated reverse osmosis brine to a state close to saturation

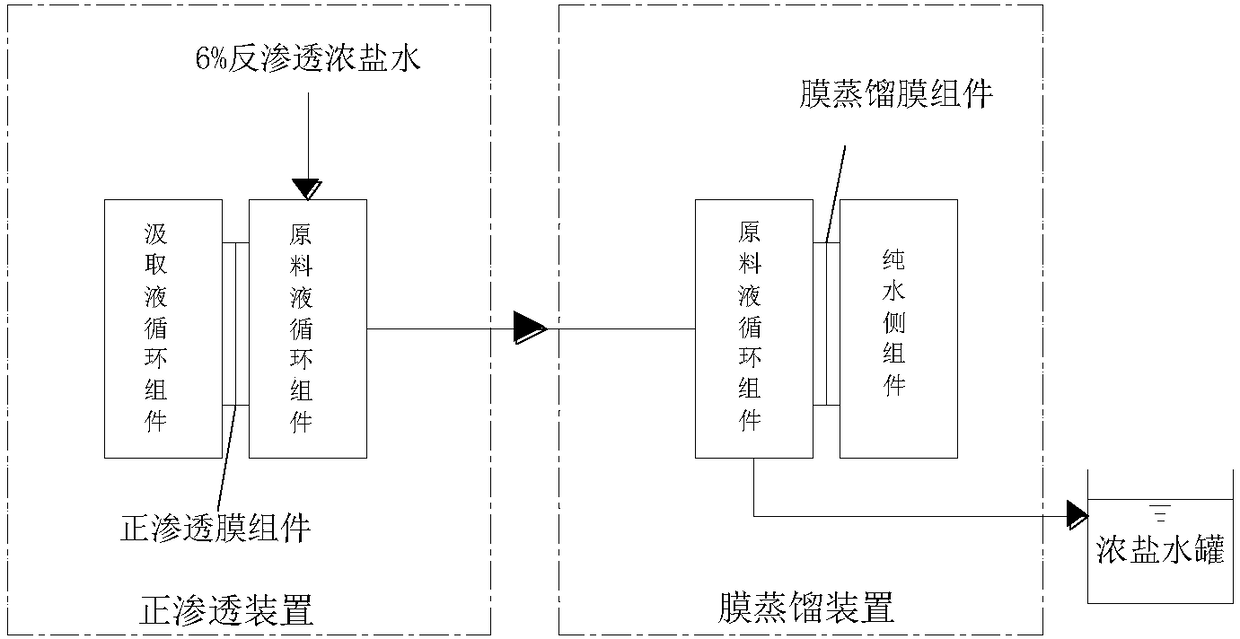

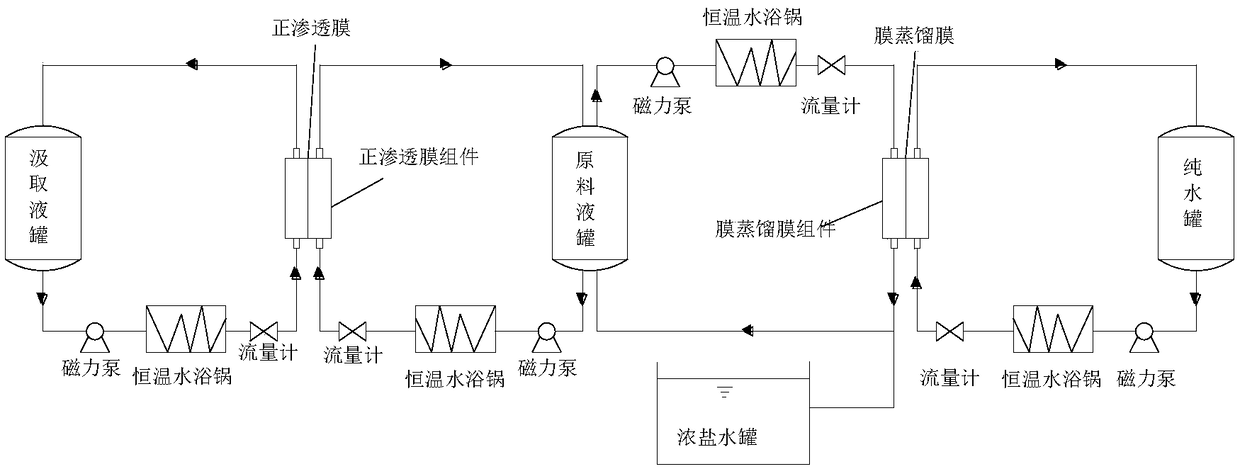

[0022] Reverse osmosis concentrated brine generally has a salt mass percentage concentration of about 6%. If the compound salt is directly extracted by spray drying technology, it will occupy a large area and consume a lot of energy. Considering this problem, it needs to be concentrated to a nearly saturated state ( Salt mass percentage concentration is about 24%), maximally increases salt concentration, reduces water volume, reduces energy consumption. The method of concentration can use the membrane distillation process, but 90% of the energy consumption in the membrane distillation process comes from the heating of the raw material liquid, and there is a phase change on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com