A kind of environment-friendly acrylate sealant and its preparation method and application

An acrylate and sealant technology, applied in the field of sealants, can solve problems such as human injury, environmental persistent pollution, and limited use range, and achieve the effects of low production cost, reduced production cost, and reduced long-term pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

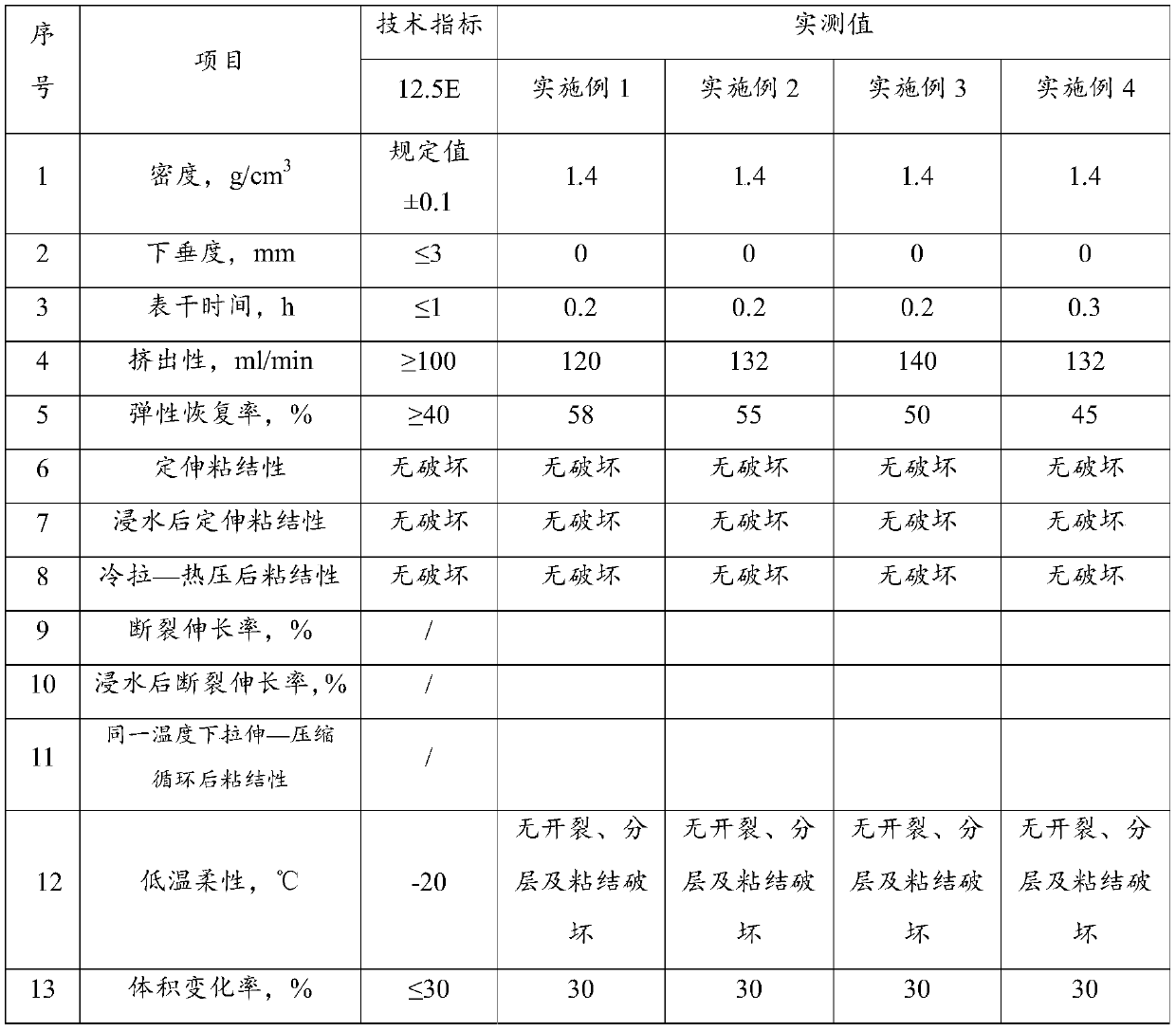

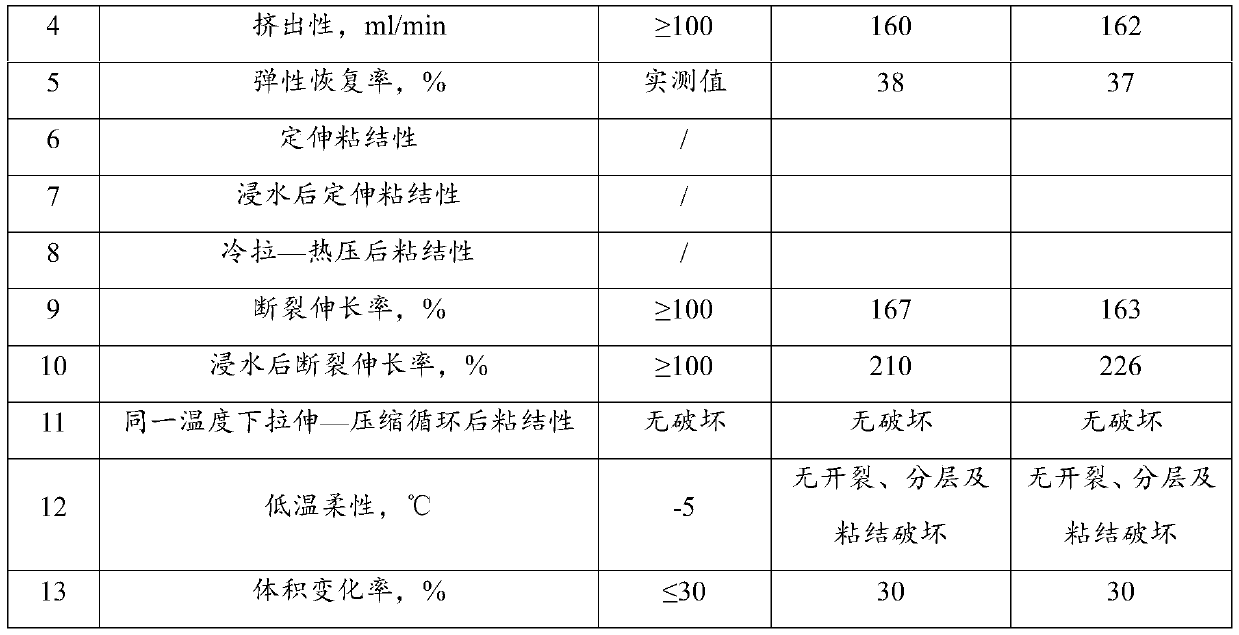

Examples

preparation example Construction

[0037] In addition, the embodiment of the present invention also provides a preparation method of the above-mentioned environment-friendly acrylate sealant, which includes the following steps: mixing elastic acrylate emulsion, wetting agent, dispersant, enhancer, odor-cleaning film-forming aid, Silane coupling agent, ground calcium carbonate and plasticizer.

[0038] Preferably, during the mixing process, it can be mixed in batches. For details, refer to the following operation: mix the dispersant, wetting agent and elastic acrylate emulsion to obtain a dispersion, and add the multifunctional additive Amp-95. Then it is mixed with enhancer and then mixed with odor-cleaning coalescent, plasticizer, silane coupling agent and ground calcium carbonate. According to this mixing sequence, the compatibility of each substance can be improved from the source, and the precipitation or floc can be avoided to affect the product quality. Among them, the multifunctional additive Amp-95 is ...

Embodiment 1

[0043] Add 100 parts by weight of elastic acrylate emulsion with a solid content of 59 wt% into the stirring tank, add 1.25 parts by weight of sodium tripolyphosphate, 1.25 parts by weight of NP-10 and 1.25 parts by weight of DA-02 during stirring , adjust the pH value to 7.5 with the multifunctional additive Amp-95. After stirring evenly, add 3 parts by weight of the specific surface area of 200m 2 / g of fumed silica, continue to stir for 5 minutes, then add 3 parts by weight of polybutene with a molecular weight of 2400, 10 parts by weight of chlorinated fatty acid methyl ester and 1.25 parts by weight of net taste film, and then slowly add 1.5 parts by weight After stirring for 10 minutes, add 100 parts by weight of 1250 mesh heavy calcium carbonate powder, stir evenly to remove air bubbles, and obtain an environmentally friendly acrylate sealant.

Embodiment 2

[0045] Add 100 parts by weight of elastic acrylate emulsion with a solid content of 61wt% into the stirring tank, add 1.25 parts by weight of sodium tripolyphosphate, 1.25 parts by weight of NP-10 and 1.25 parts by weight of DA-02 , adjust the pH value to 8 with the multifunctional additive Amp-95. After stirring evenly, add 3 parts by weight of the specific surface area of 200m 2 / g of fumed silica, continue to stir for 5min and then add 3 parts by weight of polybutene with a molecular weight of 1300, 7 parts by weight of chlorinated fatty acid methyl ester, 3.5 parts by weight of long-chain chlorinated wax and 1.25 parts by weight of Clean the odor and form a film, then slowly add 1.5 parts by weight of silane coupling agent, stir for 10 minutes, then add 100 parts by weight of 1250 mesh heavy calcium carbonate powder, stir evenly to remove air bubbles, and get an environmentally friendly acrylate sealant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com