High-strength high-toughness antimicrobial polyvinyl alcohol hydrogel and preparation method thereof

A polyvinyl alcohol, high toughness technology, applied in the field of polyvinyl alcohol hydrogel and its preparation, to achieve the effects of high tensile strength, good antibacterial properties, and enhanced action force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

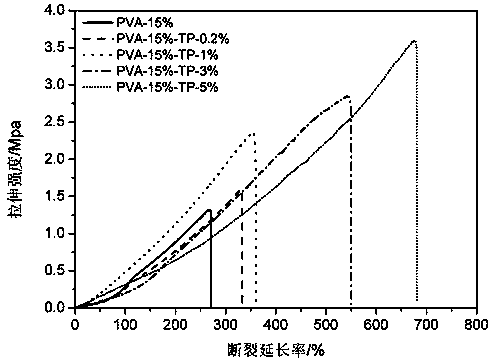

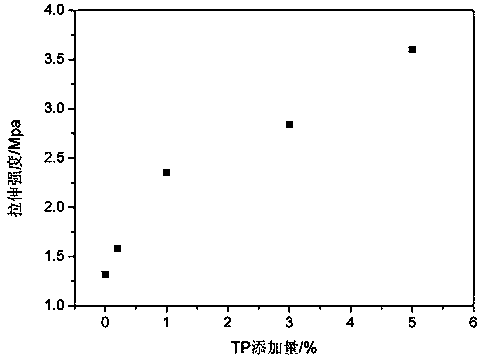

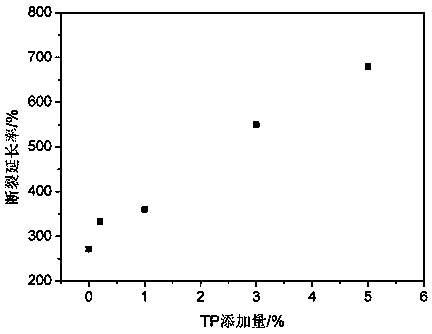

[0031] A high-strength and high-toughness antibacterial polyvinyl alcohol hydrogel is prepared from polyvinyl alcohol and tea polyphenols, and the mass ratio of polyvinyl alcohol to tea polyphenols is 15:5.

[0032] The preparation method of the above-mentioned high-strength and high-toughness antibacterial polyvinyl alcohol hydrogel comprises the steps of:

[0033] (1) Disperse 20.0 g of polyvinyl alcohol (PVA) in 80.0 g of deionized water, heat to 95°C and stir for 2 hours to prepare a high-viscosity, homogeneous 20% polyvinyl alcohol aqueous solution;

[0034] (2) Add 6.7 g tea polyphenols (TP) and 26.3 g deionized water to the above polyvinyl alcohol aqueous solution, and stir at 90°C for 30 minutes, then let it stand for 10 minutes to remove air bubbles, and prepare tea polyphenols / polyvinyl alcohol mixed liquid, the massfraction of polyvinyl alcohol in the mixed liquor is 15%, and the massfraction of tea polyphenols is 5%;

[0035] (3) Transfer the above mixture to a pa...

Embodiment 2

[0037] A high-strength and high-toughness antibacterial polyvinyl alcohol hydrogel is prepared from polyvinyl alcohol and tea polyphenols, and the mass ratio of polyvinyl alcohol to tea polyphenols is 15:3.

[0038] The preparation method of the above-mentioned high-strength and high-toughness antibacterial polyvinyl alcohol hydrogel comprises the steps of:

[0039] (1) Referring to Example 1, 100.0 g of polyvinyl alcohol aqueous solution with a mass fraction of 20% was prepared;

[0040] (2) Add 4.0g tea polyphenols and 29.0g deionized water to the above aqueous solution, and stir at 90°C for 30 minutes, then let it stand for 10 minutes to remove air bubbles, and prepare a tea polyphenol / polyvinyl alcohol mixed solution. The mass fraction of vinyl alcohol is 15%, and the mass fraction of tea polyphenols is 3%;

[0041] (3) Transfer the above mixture to a parallel glass plate mold, let it stand at room temperature for 2 hours, transfer it to -18°C and freeze it for 12 hours, ...

Embodiment 3

[0043] A high-strength and high-toughness antibacterial polyvinyl alcohol hydrogel is prepared from polyvinyl alcohol and tea polyphenols, and the mass ratio of polyvinyl alcohol to tea polyphenols is 15:1.

[0044] The preparation method of the above-mentioned high-strength and high-toughness antibacterial polyvinyl alcohol hydrogel comprises the steps of:

[0045] (1) Referring to Example 1, 100.0 g of polyvinyl alcohol aqueous solution with a mass fraction of 20% was prepared;

[0046] (2) Add 1.3g tea polyphenols and 32.0g deionized water to the above aqueous solution, stir at 90°C for 30min, then let it stand for 10min to remove air bubbles, and prepare tea polyphenol / polyvinyl alcohol mixed solution, polyvinyl alcohol mixed solution in the mixed solution The mass fraction of vinyl alcohol is 15%, and the mass fraction of tea polyphenols is 1%;

[0047](3) Transfer the above mixture to a parallel glass plate mold, let it stand at room temperature for 2 hours, transfer it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com