Non-autoclaved aerated concrete containing bauxite tailings and preparation method thereof

An air-entrained concrete and bauxite technology, applied in the field of building materials, can solve the problems of low silica content, high alumina content, and the inability to use air-entrained concrete, etc., achieving high strength, good thermal insulation performance, and far-reaching environmental protection significance and the effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

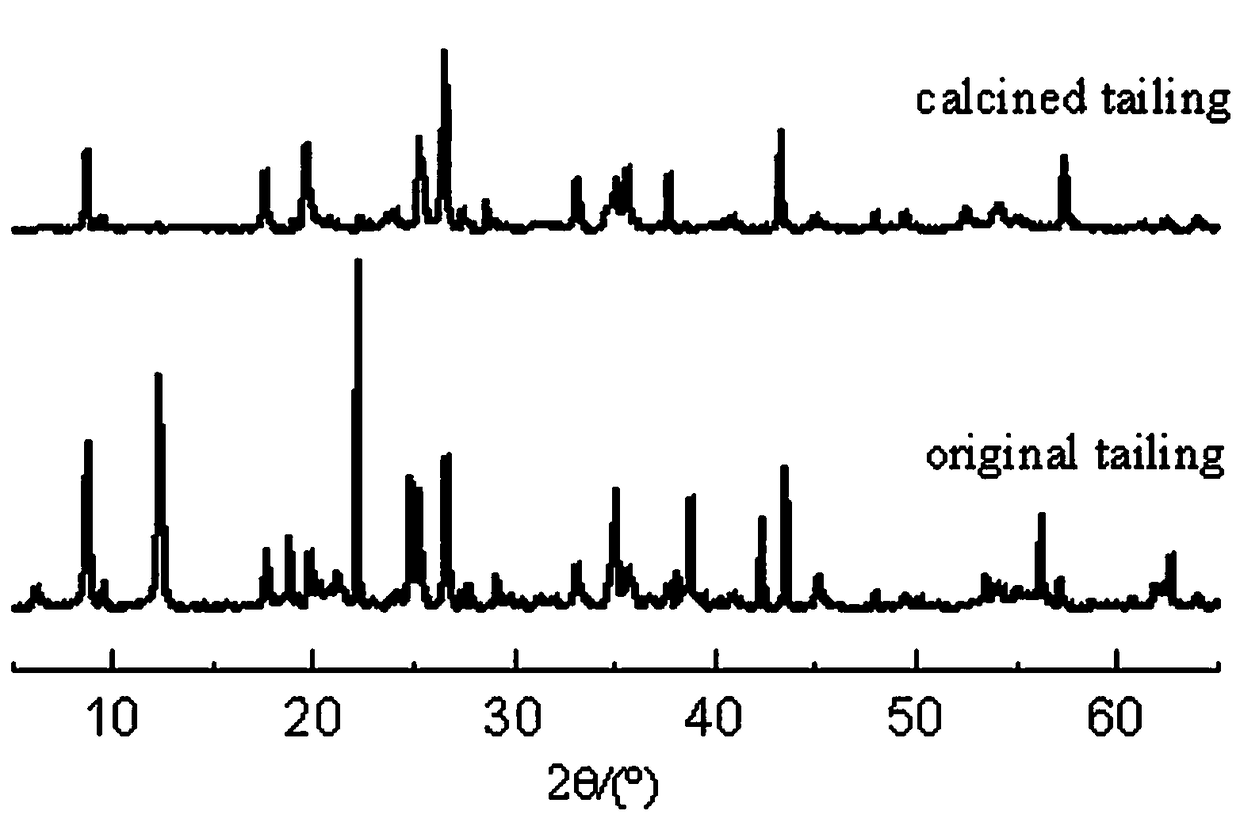

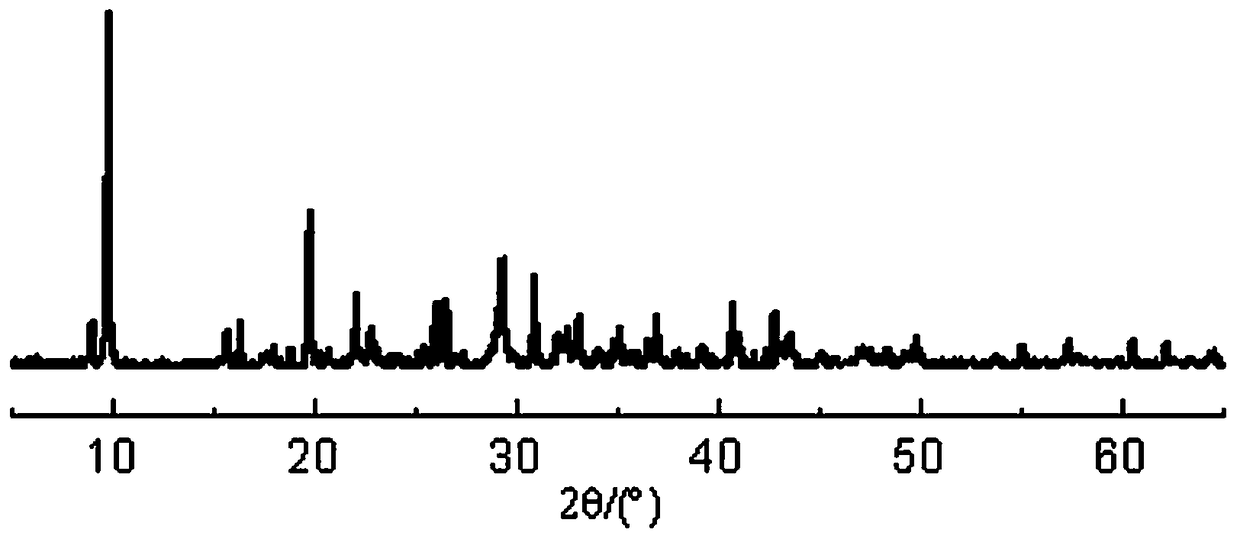

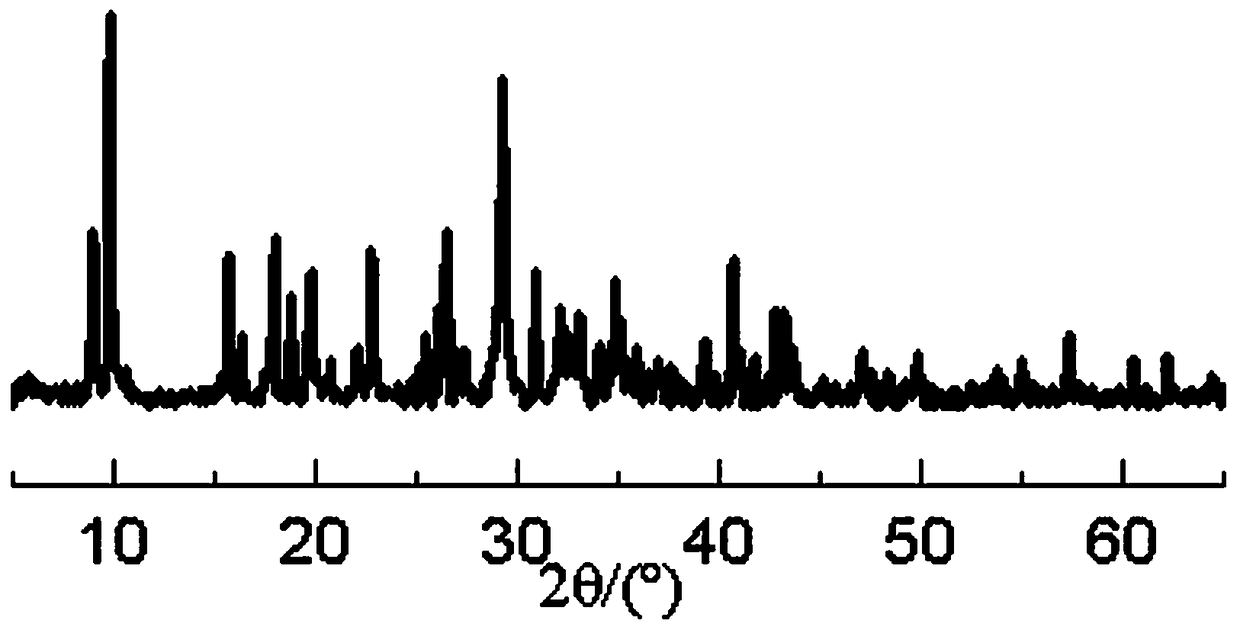

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, the non-autoclaved aerated concrete containing bauxite tailings consists of the following raw materials in parts by weight:

[0033] 10 parts of bauxite tailings powder, 50 parts of fly ash, 16 parts of lime, 8 parts of gypsum, 16 parts of cement, 63 parts of water, 0.1 part of aluminum powder paste, and 0 part of admixture.

[0034] The preparation method is as follows: firstly, stirring bauxite tailings powder, fly ash, lime, gypsum, cement and water in a container for 5 minutes; secondly, adding aluminum powder paste to the obtained slurry and continuing stirring for 3 minutes; Again, pour the evenly stirred slurry into the mold, and pre-cure for 3 hours at 65°C and a relative humidity of 100%; finally, after the pre-curing, demould, cut, and steam-cure the sample Room, under the condition of 100 ℃ steam for 20 hours, after cooling.

[0035] The specific strength of the non-autoclaved air-entrained concrete obtained in this example is 5.9×10 3 ...

Embodiment 2

[0038] In this embodiment, the non-autoclaved aerated concrete containing bauxite tailings consists of the following raw materials in parts by weight:

[0039] 20 parts of bauxite tailings powder, 30 parts of fly ash, 18 parts of lime, 12 parts of gypsum, 20 parts of cement, 65 parts of water, 0.12 parts of aluminum powder paste, 1 part of admixture, the admixture is 1 part of water glass, It is made by mixing 1 part of naphthalene-based water reducer.

[0040] The preparation method is as follows: first, stir bauxite tailings, fly ash, lime, gypsum, cement, and water in a container for 3 minutes; secondly, add aluminum powder paste and admixture to the slurry and continue stirring for 2 minutes ; Again, pour the evenly stirred slurry into the mold, and pre-cure for 4 hours at 60 ° C and a relative humidity of 100%; finally, after the pre-curing is completed, demould the sample, cut it, and put it in a steamer. In the growing room, it is steamed for 22 hours under the conditi...

Embodiment 3

[0044] In this embodiment, the non-autoclaved aerated concrete containing bauxite tailings consists of the following raw materials in parts by weight:

[0045]30 parts of bauxite tailings, 30 parts of fly ash, 22 parts of lime, 8 parts of gypsum, 10 parts of cement, 60 parts of water, 0.14 parts of aluminum powder paste, 2 parts of admixture, the admixture is 1 part of liquid caustic soda, naphthalene It is made by mixing 1 part of superplasticizer.

[0046] The preparation method is as follows: firstly, stir raw materials such as bauxite tailings, fly ash, lime, gypsum, cement and water in a container for 5 minutes; secondly, add aluminum powder paste and admixture to the slurry and continue stirring 3 minutes; again, pour the evenly stirred slurry into the mold, and perform pre-curing for 4 hours at 50°C and a relative humidity of 95%; finally, after the pre-curing, demould and cut the sample, Put it into a steaming room, steam it for 24 hours under the condition of 80°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific strength | aaaaa | aaaaa |

| Specific strength | aaaaa | aaaaa |

| Specific strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com