Automobile surface protective film and spraying liquid used thereby

A technology for automobile surface and protective film, applied in the field of spraying liquid, can solve the problems of deformed and damaged passengers and drivers, cars with low impact resistance, poor impact resistance of wax molds, etc., and achieves enhanced bonding performance, high damping coefficient, The effect of reducing the degree of cross-linking with formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

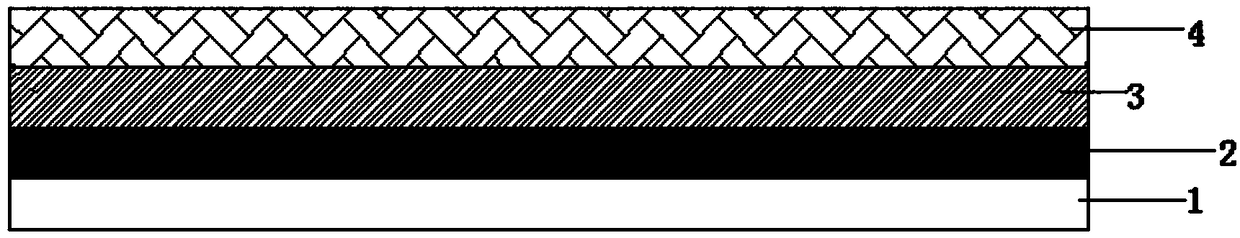

[0035] Automotive surface protective film, such as figure 1 As shown, it includes sequentially coating a base film 1, a sound insulation film 2, a rigid film 3 and a peelable protective film 4 compounded on the surface of the car;

[0036] The specific forming process of the protective film is as follows:

[0037] (1) First coat a layer of base film on the surface of the car, after the base film is formed and dried, compound a layer of sound-insulating colloid on the surface of the base film, and then air-dry at room temperature;

[0038] (2) After the colloid is air-dried, apply a layer of rigid spraying liquid on the surface of the colloid to obtain a rigid film after air-drying, and simultaneously spray a layer of peelable protective coating on the surface of the rigid film, and air-dry at room temperature to obtain a protective film.

[0039] The preparation and coating process of the sound-insulating colloid are:

[0040] (1) Put 7kg of EVA resin and 1.6kg of PVC resin ...

Embodiment 2

[0047] Wherein the preparation process of the spraying liquid that automobile surface protective film uses among the embodiment 1 is:

[0048] (1) Dissolve 1.1kg of catechol in 1.5kg of water, then heat to 70°C, add 0.94kg of hydroxy silicone oil while stirring, stir and react for 30-50min, then add 0.9kg of formaldehyde solution with a mass fraction of 37%, Adjust the pH of the reaction solution to 12.5 and stir at 70°C for 50-80 minutes;

[0049](2) Then add 0.72 kg of hydroxypropyl cellulose and stir to dissolve, then add 8.6 kg of formaldehyde solution to adjust the pH of the solution to 13, and then stir for 1-2 hours;

[0050] (3) Finally, add 0.143 kg of XC-100TJ hydrophilic nano-titanium dioxide, stir and mix evenly, then add 0.23 kg of formaldehyde solution, heat up to 80 ° C for 3-5 hours, and obtain a spraying liquid;

[0051] (4) Then the spray liquid prepared in step 3 is directly sprayed to the surface of the car through a high-pressure spray gun at 80°C, and th...

Embodiment 3

[0053] Automotive surface protective film, such as figure 1 As shown, it includes sequentially coating a base film 1, a sound insulation film 2, a rigid film 3 and a peelable protective film 4 compounded on the surface of the car;

[0054] The specific forming process of the protective film is as follows:

[0055] (1) First coat a layer of base film on the surface of the car, after the base film is formed and dried, compound a layer of sound-insulating colloid on the surface of the base film, and then air-dry at room temperature;

[0056] (2) After the colloid is air-dried, apply a layer of rigid spraying liquid on the surface of the colloid to obtain a rigid film after air-drying, and simultaneously spray a layer of peelable protective coating on the surface of the rigid film, and air-dry at room temperature to obtain a protective film.

[0057] The preparation and coating process of the sound-insulating colloid are:

[0058] (1) Put 8.5kg of EVA resin and 2.1kg of PVC resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com