Wool processing device

A processing device and wool technology, which are applied in the directions of transportation and packaging, decomposition of fibrous substances, and fiber processing, etc., can solve the problems of the wool not being effectively sorted, the wool straightening function not being realized, and the wool being easily entangled and knotted. The effect of saving physical strength, high degree of automation, avoiding entanglement and knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

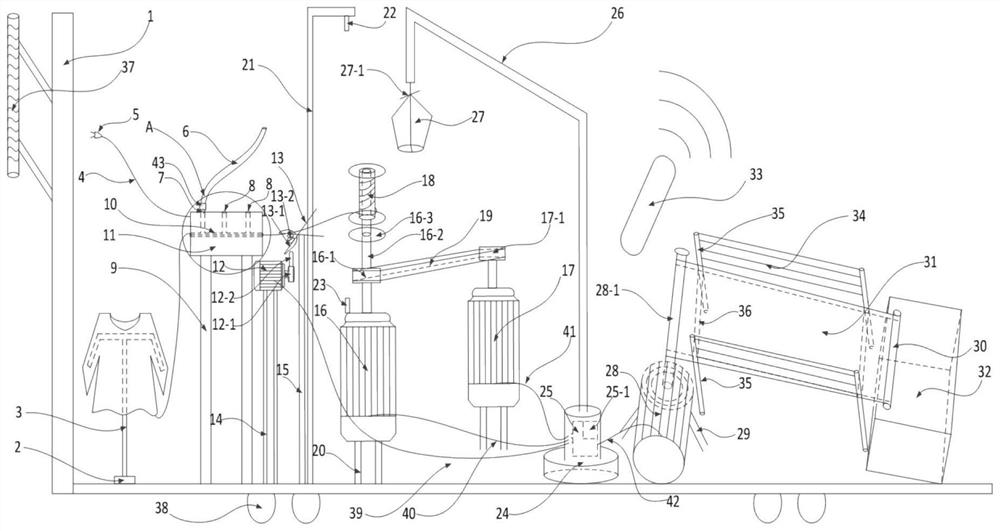

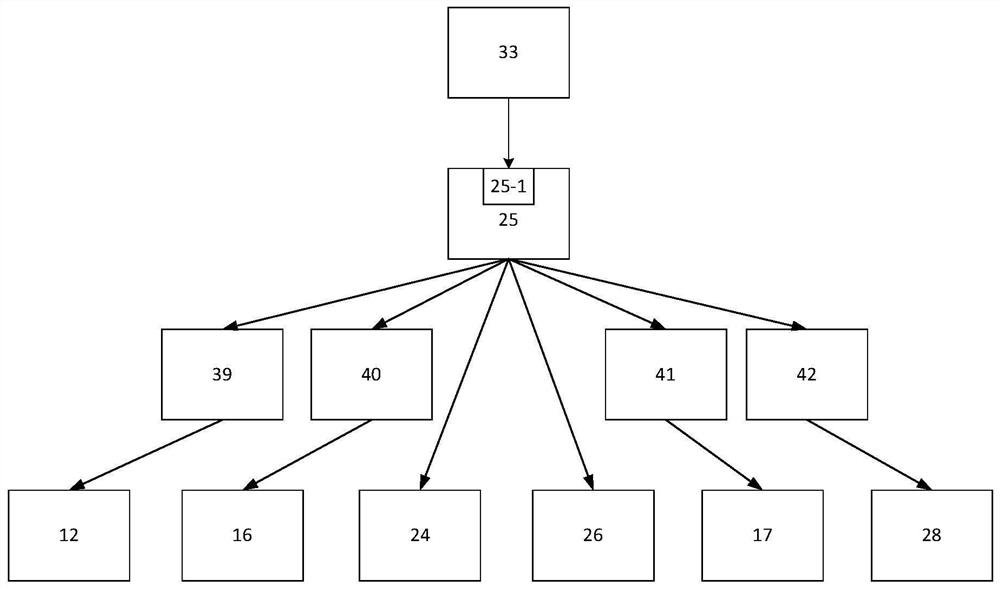

[0037] Embodiment: a kind of wool processing device, such as Figure 1 to Figure 3 As shown, it includes a frame 1, a drying and straightening device fixed on the frame, a thread cutting device, a winding device, and a winding conveying device;

[0038] A bearing 2 is fixed on the frame, and the bearing is rotatably connected to the lower end of the "T"-shaped fixed frame 3, and the sweater is placed on the "T"-shaped fixed frame;

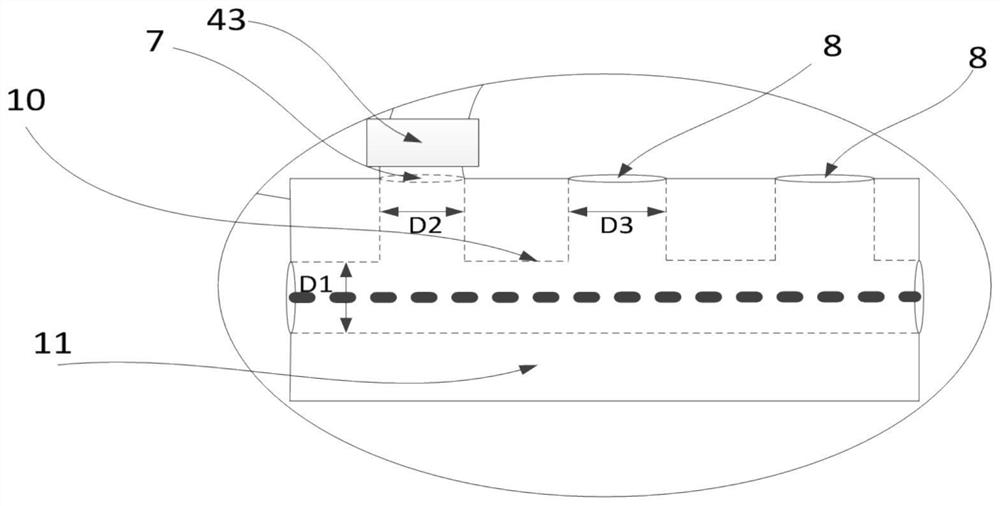

[0039] The ironing and straightening device includes a power cord 4, a plug 5, a water injection pipe 6, a water injection hole 7, an air outlet 8, a first support rod 9, an incoming electric heating tube 10 and an ironing box 11, and one end of the power cord It is electrically connected with the plug, and the other end of the power cord is electrically connected with the incoming electric heating pipe. The air outlet hole, the water injection hole is fixedly connected with the water injection pipe, the connection between the water injection hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com