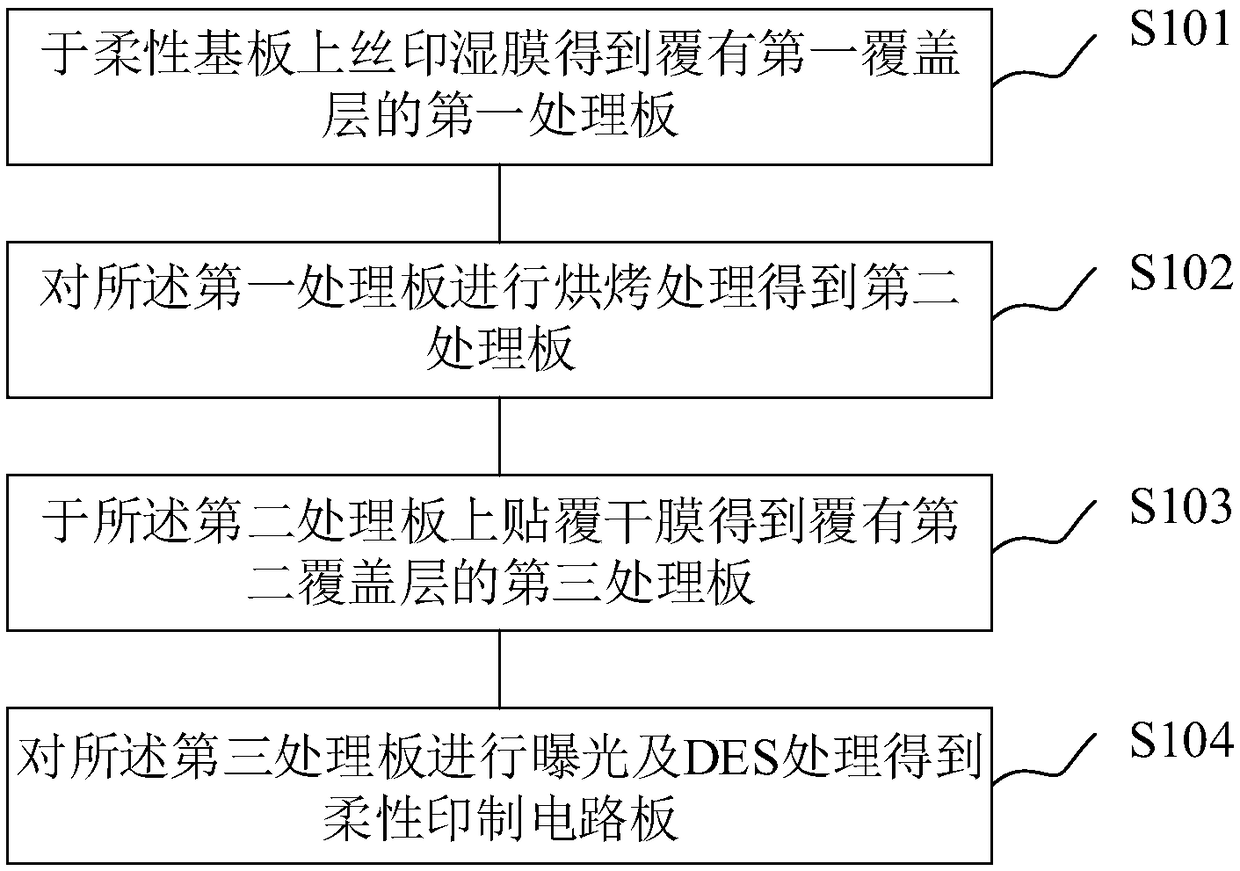

Preparation method of flexible printed circuit board

A flexible printing and circuit board technology, applied in printed circuit manufacturing, laminated printed circuit boards, printed circuits, etc., can solve problems such as defective flexible printed circuit boards, improve the flatness of the board surface, and reduce the height difference , reduce the effect of open circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] The processing of printed circuit boards in the way of selective copper plating can meet the flexible requirements of contemporary printed circuit boards, aiming at the step structure formed when the copper plating area and the non-copper plating area connected to the copper plating area have a height difference , especially when the height difference is greater than or equal to 40 microns, the printed circuit board prepared according to the traditional process may cause a short circuit caused by poor exposure during the exposure stage due to the height difference. Leading to problems such as scrapping, the present invention provides a method for preparing a flexible printed circuit board to solve or partially solve the above pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com