Non-overlapping winding double-side AC linear motor

A linear motor, non-overlapping technology, applied in the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc., can solve the problem that cannot be applied to long strokes, and the two-coil side embedding method cannot be used for segmented manufacturing, etc. problems, to achieve the effect of simple structure, easy insulation, weakening vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

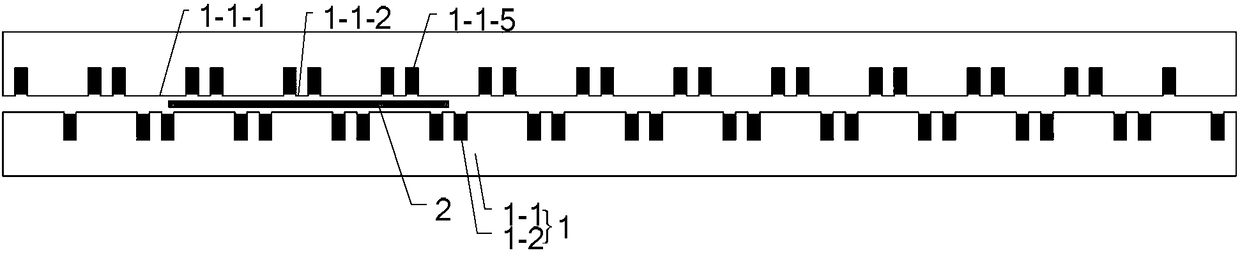

[0039] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment in detail. The bilateral AC linear motor with non-overlapping windings described in this embodiment includes a bilateral primary 1 and a secondary 2. There is an air gap between the bilateral primary 1 and secondary 2, and each primary includes a primary iron core 1- 1 and primary winding 1-2;

[0040]Grooves are made on the air gap side surface of each primary core 1-1 along the transverse direction, forming large teeth 1-1-1, shallow grooves 1-1-3, small teeth 1-1-2, and deep grooves 1-1- 4. Arranged along the direction of movement, each two adjacent large teeth 1-1-1 include 5 slots and 4 small teeth 1-1-2, the slots and small teeth 1-1-2 are arranged alternately, and each The two adjacent grooves of a large tooth 1-1-1 are shallow grooves 1-1-3, the other grooves are deep grooves 1-1-4, and the depth of deep groove 1-1-4 is shallow groove 1-1 -2 times the depth of the groo...

specific Embodiment approach 2

[0043] Specific implementation mode two: combination image 3 Describe this embodiment in detail. The bilateral AC linear motor with non-overlapping windings described in this embodiment includes a bilateral primary 1 and a secondary 2. There is an air gap between the bilateral primary 1 and secondary 2, and each primary includes a primary iron core 1- 1 and primary winding 1-2;

[0044] Slots are made on the air gap side surface of each primary core 1-1 along the transverse direction, and the small teeth 1-1-2, slots 1-1-5, and large teeth 1-1-1 formed are arranged along the moving direction;

[0045] Large teeth 1-1-1 pitch t s2 and polar distance τ p satisfies the relation 3t s2 =4τ p , large tooth 1-1-1 tooth width b s2 , small teeth 1-1-2 pitch t s1 , small tooth 1-1-2 tooth width b s1 satisfies the relation b s2 = 2t s1 +b s1 ;

[0046] The primary winding 1-2 is a concentrated full-pitch winding. There is a coil wound on each large tooth 1-1-1. The coils on t...

specific Embodiment approach 3

[0047] Specific implementation mode three: combination Figure 4 Describe this embodiment in detail. The bilateral AC linear motor with non-overlapping windings described in this embodiment includes a bilateral primary 1 and a secondary 2. There is an air gap between the bilateral primary 1 and secondary 2, and each primary includes a primary iron core 1- 1 and primary winding 1-2;

[0048] Slots are made on the air gap side surface of each primary core 1-1 along the transverse direction to form teeth 1-1-6;

[0049] Tooth pitch t s and polar distance τ p satisfies the relation 3t s = 2τ p ;

[0050] The primary winding 1-2 is a concentrated winding with fractional slots, a coil is wound on each tooth 1-1-6, the coils on adjacent teeth 1-1-6 belong to different phases, and the windings of the corresponding phase coils on both sides of the secondary 2 On the contrary, all the coils on the same side of the secondary 2 are connected into a three-phase symmetrical winding, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com