Instantaneous refrigeration beer machine

The technology of a beer machine and a refrigeration device is applied in the field of beer refrigeration, which can solve the problems of not being able to control the optimal drinking temperature, energy loss, wasting energy, etc., and achieve the effects of simple structure, control of cooling temperature, and convenient use and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

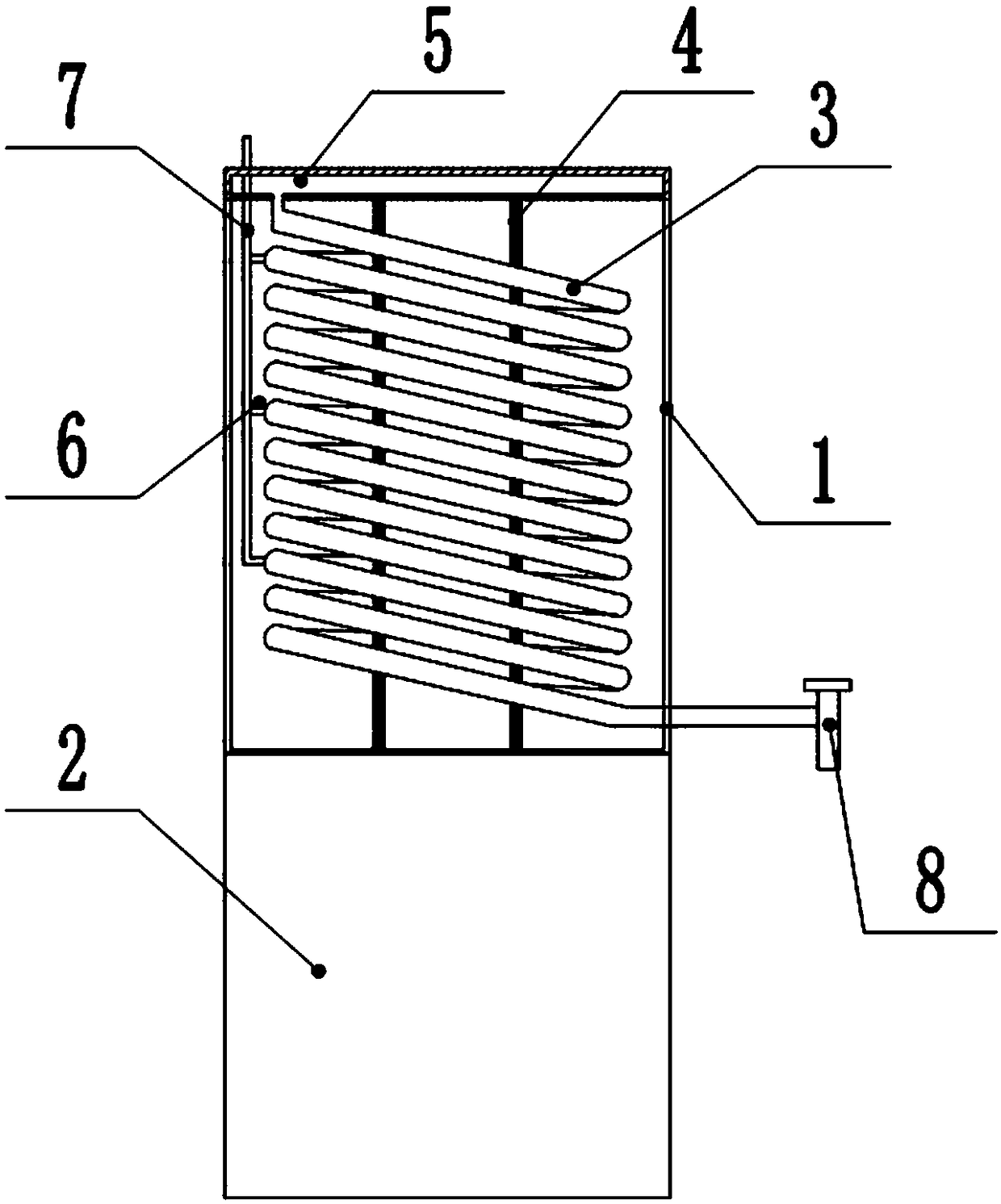

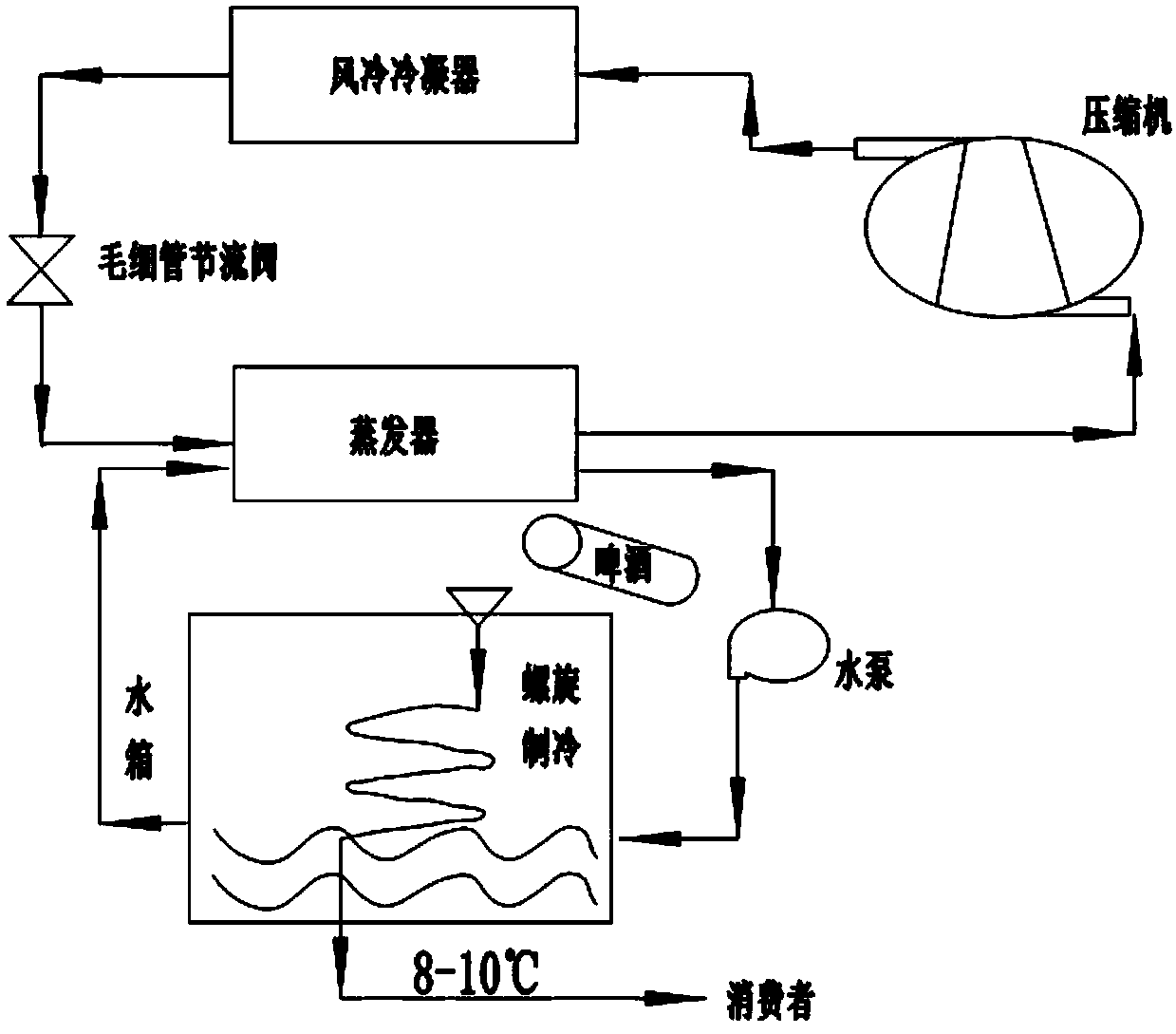

[0014] Please refer to figure 1 and figure 2 , according to the present invention, a kind of instantaneous cooling beer machine, comprising a water tank 1, a spiral coil heat exchanger 3 is installed in the height direction of the water tank 1, the upper end opening of the spiral coil heat exchanger 3 and the wine injection device installed above it The container 5 is connected, the outlet at the bottom of the spiral coil heat exchanger 3 extends out of the water tank 1, and a faucet 8 is installed to control its opening and closing. The inner bottom of the water tank 1 is provided with a cooling liquid inlet and a cooling liquid outlet. The liquid port is connected with the output port of the liquid refrigeration device, and the cooling liquid outlet is connected with the input port of the liquid refrigeration device.

[0015] The above structure is the core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com