Flameless burner control system, flameless low-NOx burner and control method thereof

A technology of control system and ignition controller, which is applied in the combustion method, control combustion, burner and other directions, can solve the problems of inefficient energy, increase production cost, and high NOx, achieve convenient operation, reduce local high temperature of flame, and uniform flue gas temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with specific embodiments.

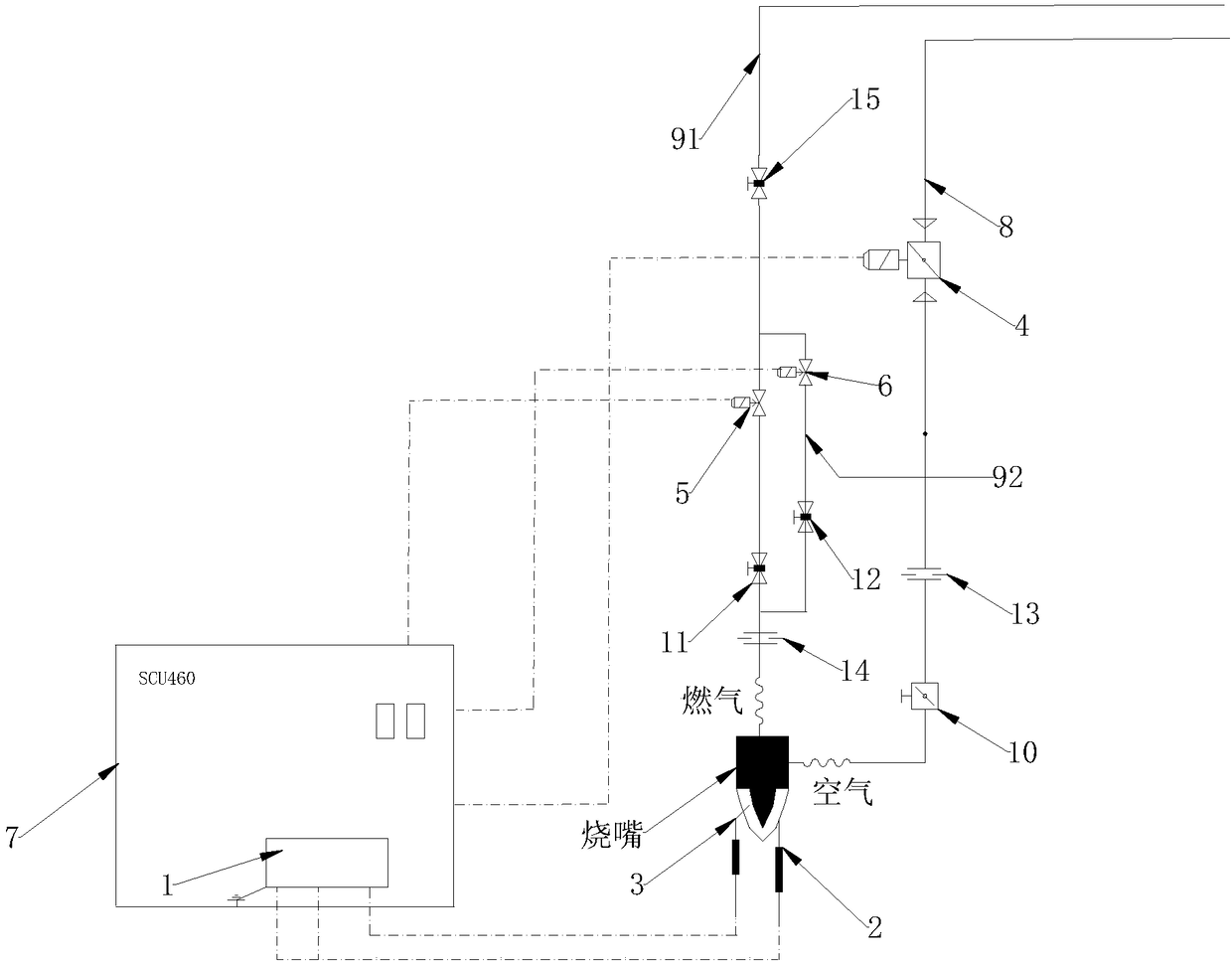

[0035] see figure 1As shown, the present invention relates to a flameless burner control system, including ignition transformer 1, ignition electrode 2, detection electrode 3, air solenoid valve 4, first gas solenoid valve 5, second gas solenoid valve 6, and SCU460 ignition control device 7, the ignition electrode 2 and detection electrode 3 are set at the place where gas and air are mixed in the flameless burner, the air solenoid valve 4 is set on the air pipe 8 communicating with the flameless burner, and the first gas solenoid valve 5 is set On the first gas pipe 91 communicating with the flameless burner, the first gas pipe 91 is connected in parallel with the second gas pipe 92 located at both ends of the first gas solenoid valve 5, and the second gas solenoid valve 6 is arranged on the second gas pipe. 92; wherein the gas control output end of the SCU460 ignition c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com