Channel automatic switching device and control method thereof

An automatic switching and progressive technology, applied in the direction of rolling force/gap control, metal rolling, manufacturing tools, etc., can solve the problems of labor waste, high labor intensity, monotony, etc., and achieve reliable operation, low cost, and easy use simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

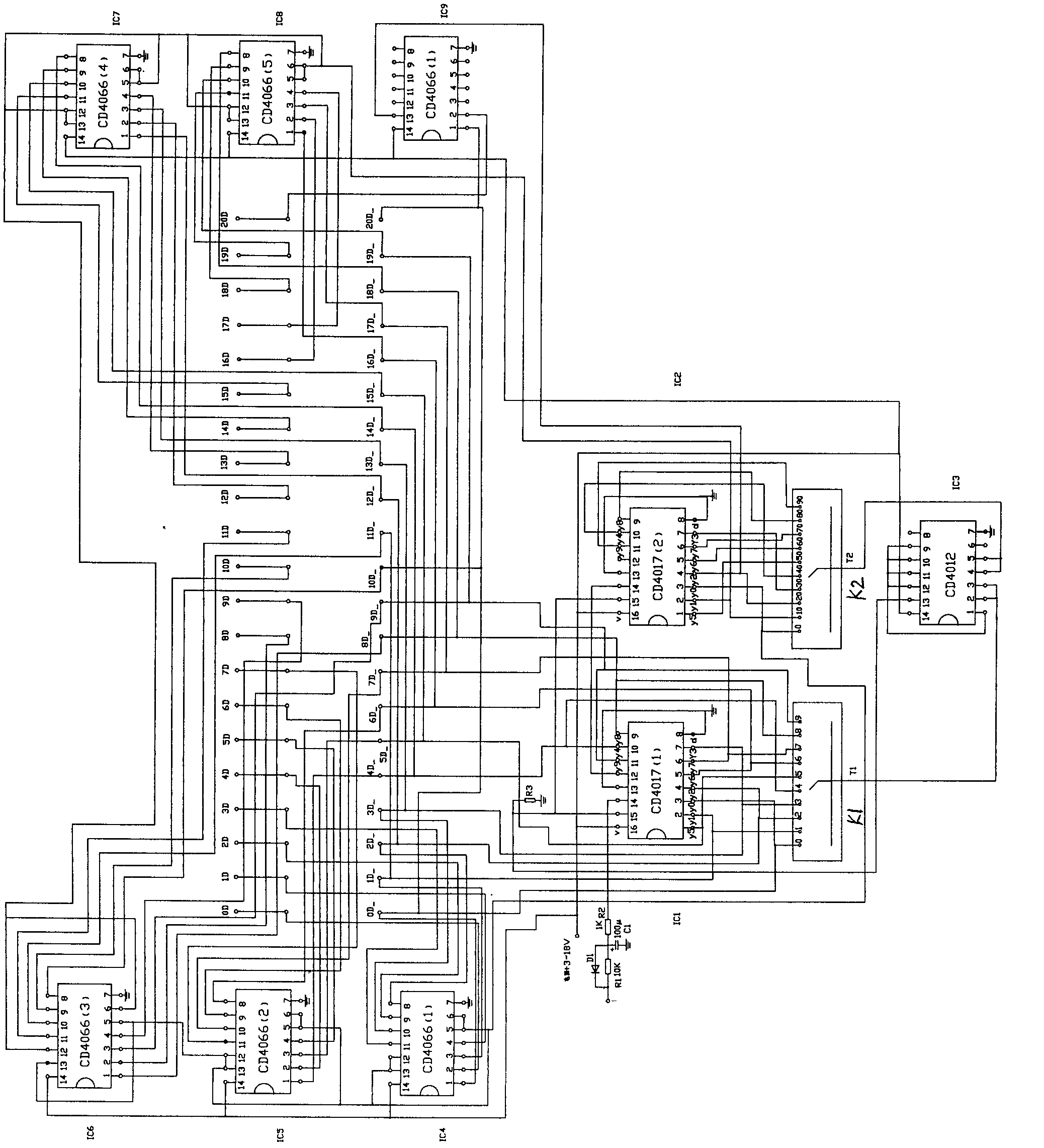

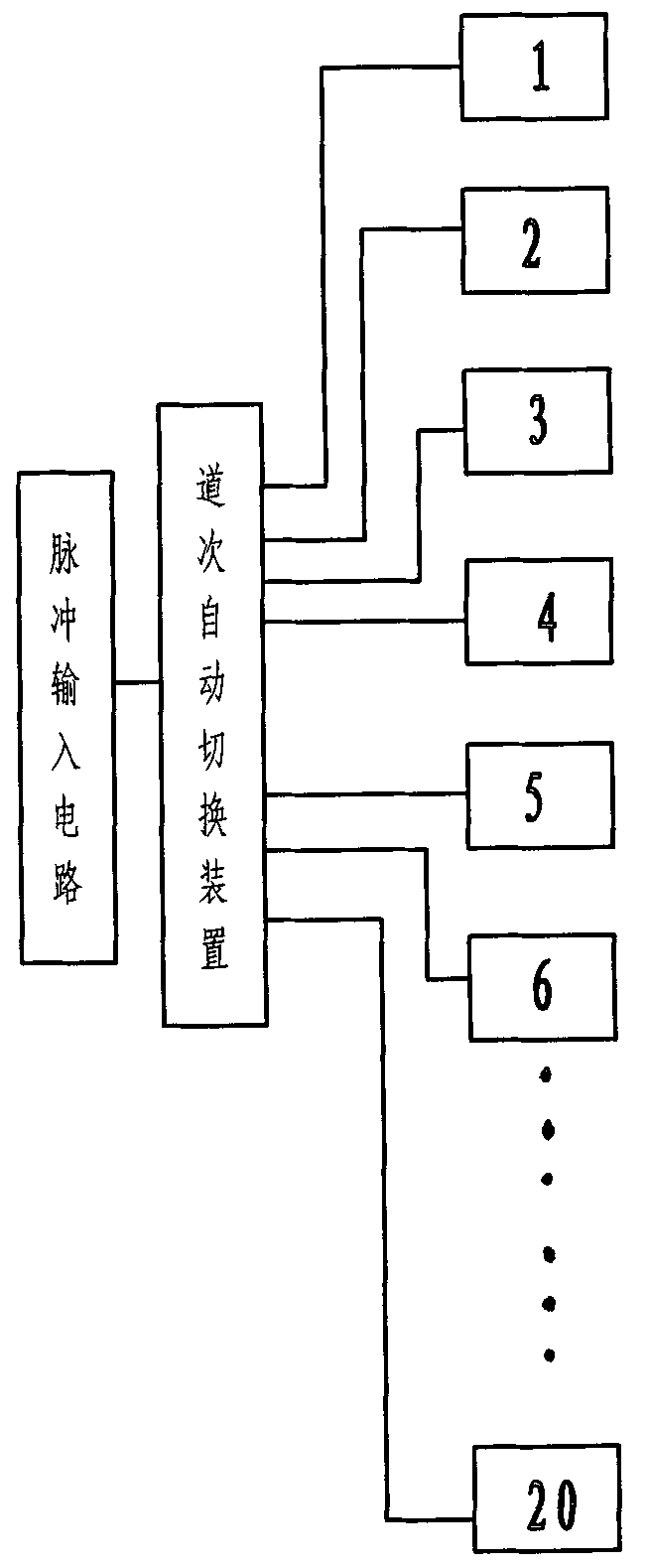

[0036] Embodiment: This embodiment is an example of testing on a four-high rolling mill of Shanxi Taigang Stainless Steel Co., Ltd. Stainless Steel Hot Rolling Plant.

[0037] The universal rolling mill of Shanxi Taigang Stainless Steel Co., Ltd. Stainless Hot Rolling Plant is a four-high reversing rolling mill, and the rolled steel plates need multiple reversing rolling. The rolling of the steel plate is completed by adjusting the roll gap between the rolls. Every time the rolling is completed, the roll gap is adjusted once, which is called a pass. The number of rolling passes is different for different steel types and specifications. Under the same working conditions, for the same steel type and specification, the number of passes is certain. In the process of steel rolling in the four-high rolling mill, after each pass is rolled, the roll gap of the next pass is adjusted to carry out rolling, and after rolling, the roll gap adjustment of the next pass is adjusted until all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com