Self-resetting prestressed laminated wood frame structure

A frame structure and prestressing technology, used in building components, building structures, earthquake resistance, etc., can solve problems such as insufficient energy dissipation capacity, brittle splitting failure of joints, and large residual deformation, so as to improve seismic performance and prevent brittle splitting. The effect of crack damage and reduction of residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

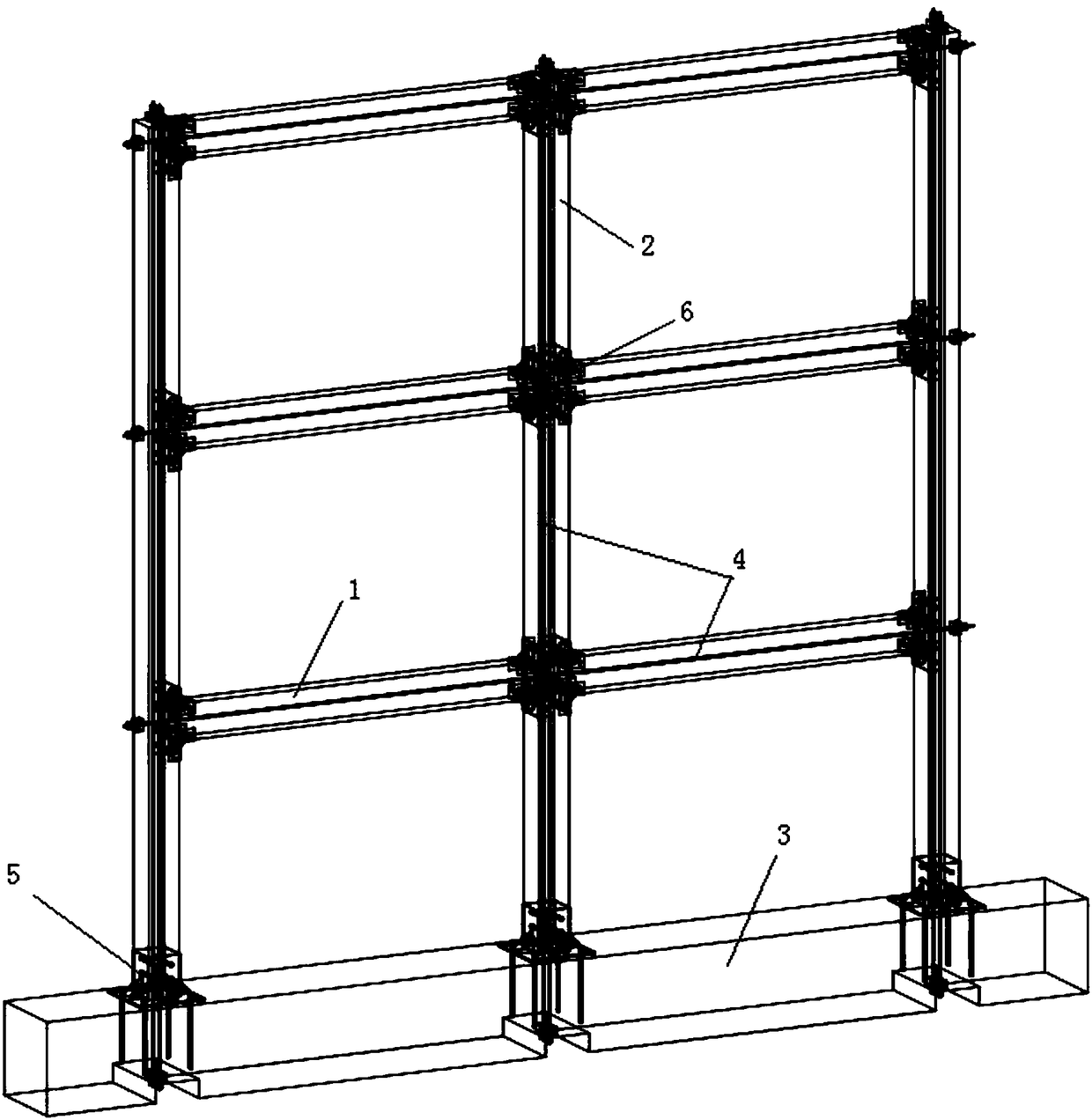

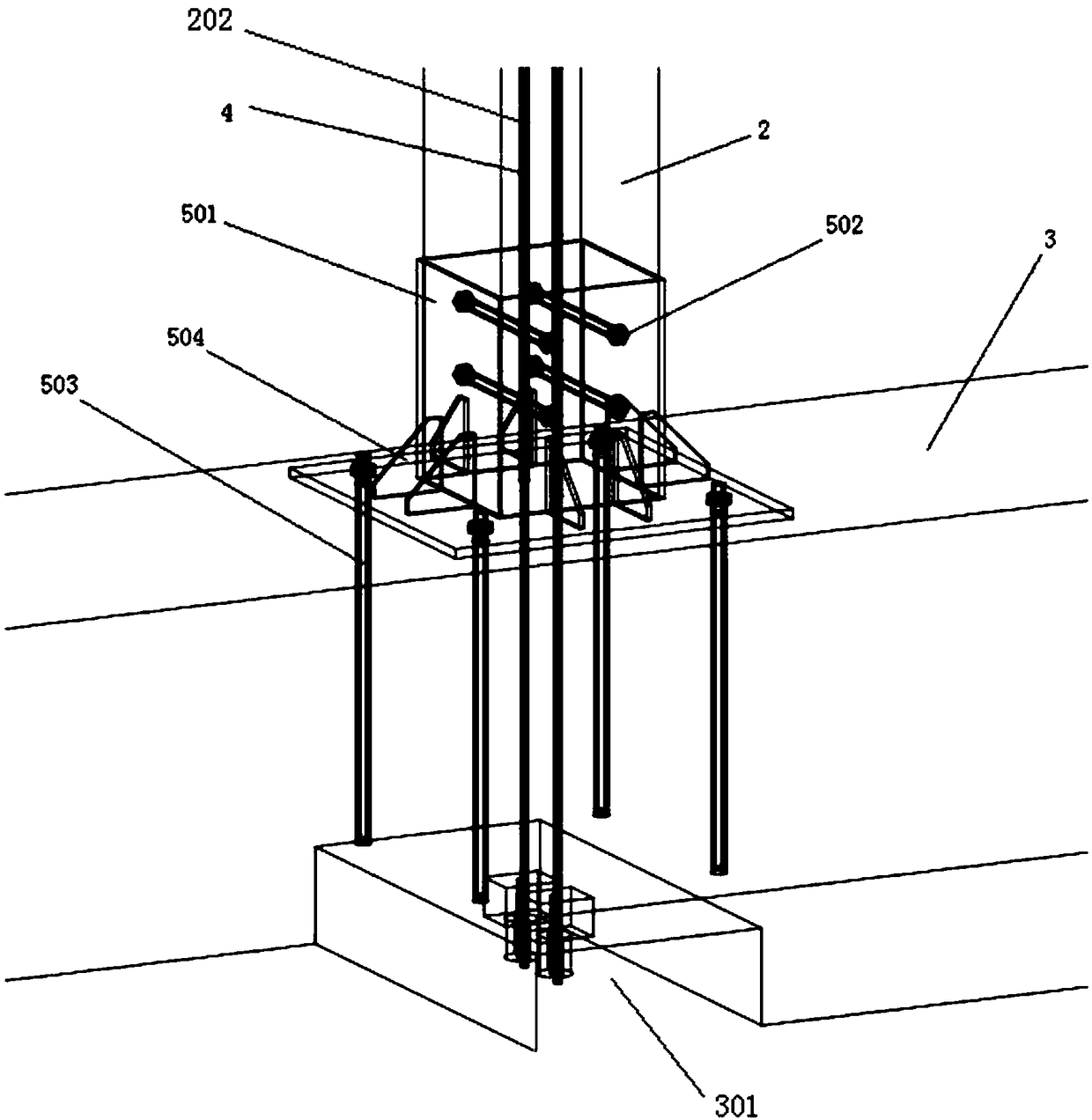

[0023] as attached Figure 1~4 As shown, a self-resetting prestressed glulam frame structure, which includes glulam beams 1, glulam columns 2, reinforced concrete foundation 3, prestressed steel bars 4, column foundation metal connectors 5 and beam-column metal connectors 6. The glued wood column 2 is fixed on the reinforced concrete foundation 3 by using the metal connector 5 of the column foundation, and the glued wood beam 1 and the glued wood column 2 form a frame structure by using the beam-column metal connector 6;

[0024] The column base metal connector 5 includes a steel column shoe 501, connecting bolts 502, column shoe and foundation connecting steel bars 503 and column base stiffeners 504, and the glued wood column 2 and steel column shoe 501 are connected through the connecting bolts 502 connection, the steel column shoe 501 is connected to the reinforced concrete foundation 3 by using the column shoe and the foundation connecting steel bar 503, and the glued wood...

Embodiment 2

[0031] as attached Figure 5 As shown, the glulam beam 1 is provided with a slot 601a at a position corresponding to the first outer steel plate 601 and the second outer steel plate 602, and the inner rib 605 is installed in the slot 601a. Other structures are the same as in Embodiment 1.

[0032] The present invention provides a self-resetting prestressed glulam frame structure, in which prestress is applied to the glulam frame to increase the horizontal stiffness of the frame, to realize self-adaptation during earthquakes and self-reset after earthquakes, and to reduce structural residues out of shape. Utilizing the excellent mechanical properties of glulam, combined with the beam-column connection form of ribbed outsourcing steel plates, it can effectively prevent brittle splitting damage of joints, enhance the rotational capacity and ductility of joints, and form an efficient and stable rotational energy consumption mechanism of joints, thus improving conventional joints....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com