Plating layer or passivation layer preparing device capable of flexibly controlling environment parameters and using method

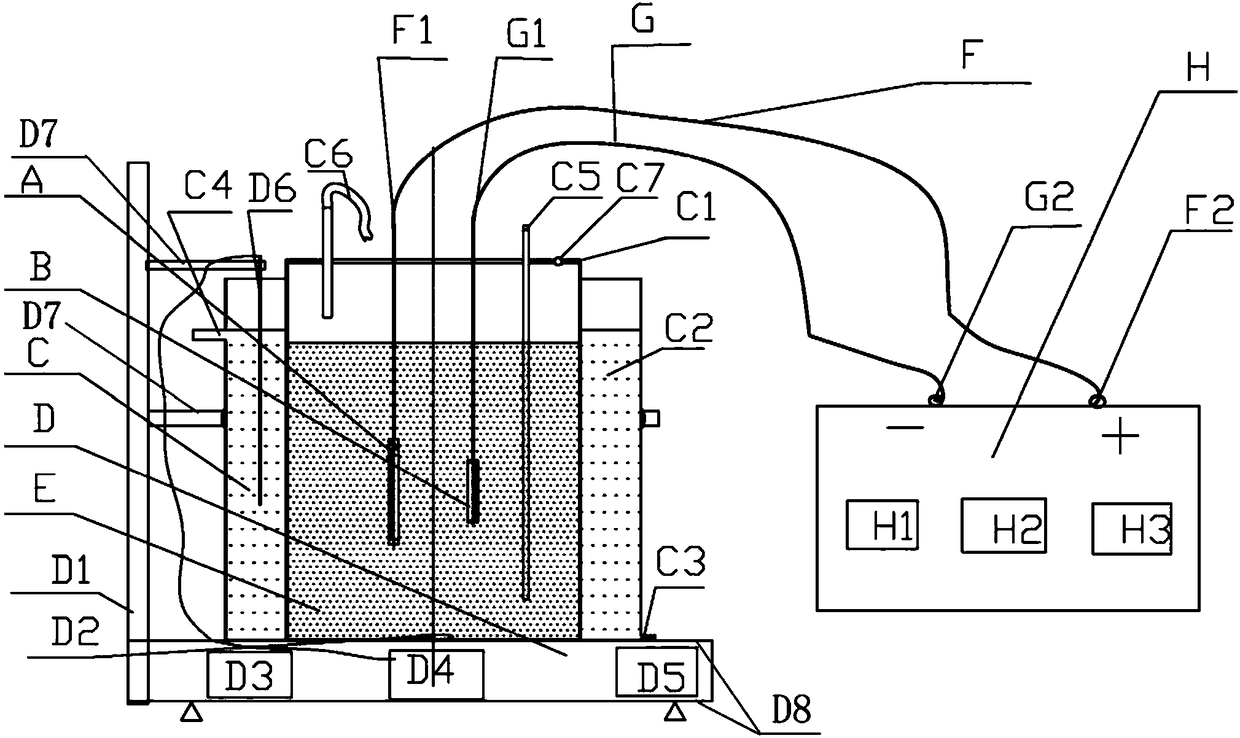

A technology for controlling the environment and preparing the device, which is used in coatings, surface reaction electrolytic coatings, electrolytic coatings, etc., can solve problems such as poor controllability and troublesome maintenance, and achieve the effects of low cost, stable operation, and ensuring the uniformity of electric field lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

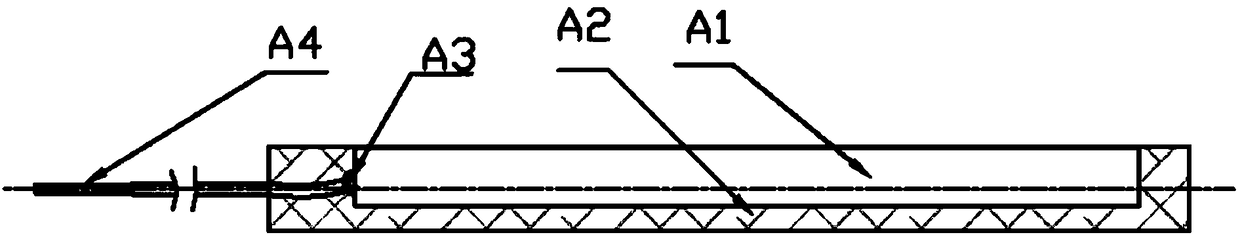

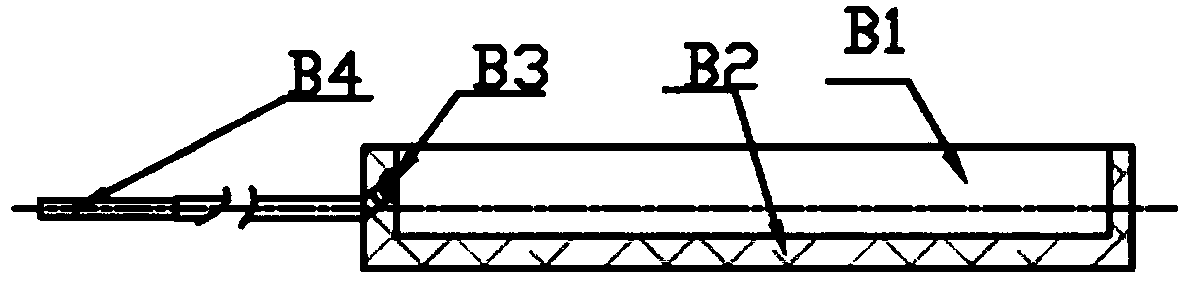

[0075] The measurement of the potential E and dissolved oxygen standard curve of cathode B vs anode A in the electro-galvanizing bath at room temperature 25°C is as follows:

[0076] The experimental material of cathode B to be treated is domestic commercially available Q235 carbon steel, and the material of anode A is commercially available 99.99wt% high-purity titanium sheet. Commercially available basic cyanide-free electrolytic zinc at room temperature has a composition of 10g / L ZnCl 2 , 120g / L NaCl, 850 type alkaline electro-galvanizing brightener A, moving agent B and purifying agent C are 6mL / L, 1mL / L and 2mL / L respectively, the rest is water, and the pH value is controlled at 3.0. According to Nernst's law E=E 0 +2.3RT / F·ln(p / p θ ), and E has a logarithmic relationship with DO. Obtaining the standard curve of E∝DO of B vs A in advance can facilitate the indirect control of the dissolved oxygen DO of the solution through E later. The measurement of this experiment E...

Embodiment 2

[0082] Domestic Q235 steel is electroplated with zinc + trivalent chromium passivation in the electrolyte of electroplating or passivation treatment pool C at room temperature as follows:

[0083] The experimental material of the cathode to be treated is domestic commercially available Q235 carbon steel, and the anode material is commercially available 99.99wt% high-purity titanium sheet. Experimental electro-galvanizing process: the electrolyte is as in Example 1, the temperature T is 25°C, and the dissolved oxygen DO is 0.1mol / L (ppm). The FC-85 trivalent chromium blue-white passivation solution sold by Suzhou Jizhimei Surface Treatment Materials Co., Ltd. is selected for the experiment. The temperature is 25°C, and the pH value is controlled at 2.0. The experimental steps are as follows:

[0084] (1) Electroplating experiment preparation: Add 300mL galvanized electrolyte solution to a 500mL electroplating or passivation treatment pool, place a magnetic stirrer in the soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com