Soil conditioner and preparation method thereof

A soil improver, agricultural technology, applied in the direction of application, organic fertilizer, nitrogen fertilizer, etc., can solve the problems of changing soil physical and chemical structure, reducing visibility, etc., to achieve the effect of improving biological communities, improving water and fertilizer retention capacity, and improving properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

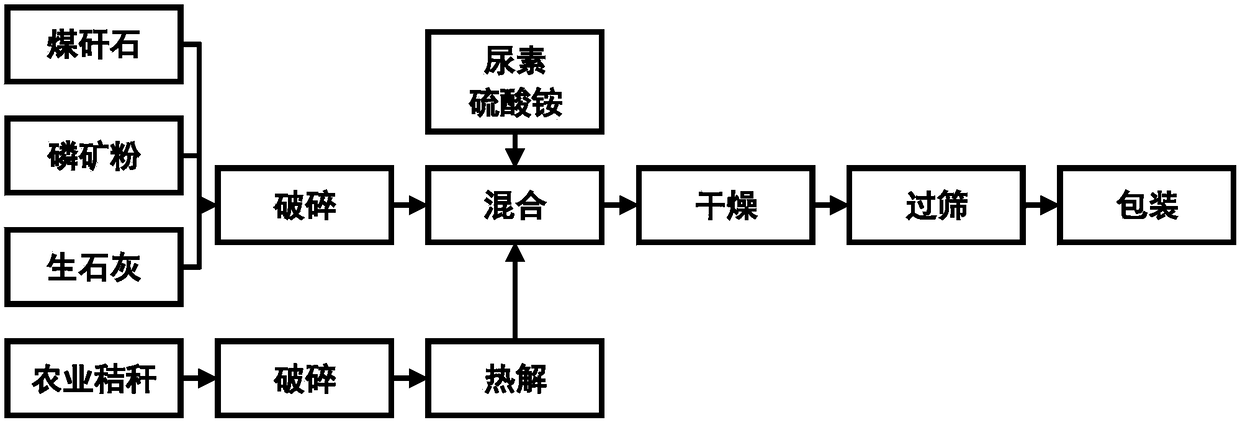

[0029] The present invention also provides a preparation method of the soil conditioner, the specific preparation process is as follows: figure 1 shown, including the following steps:

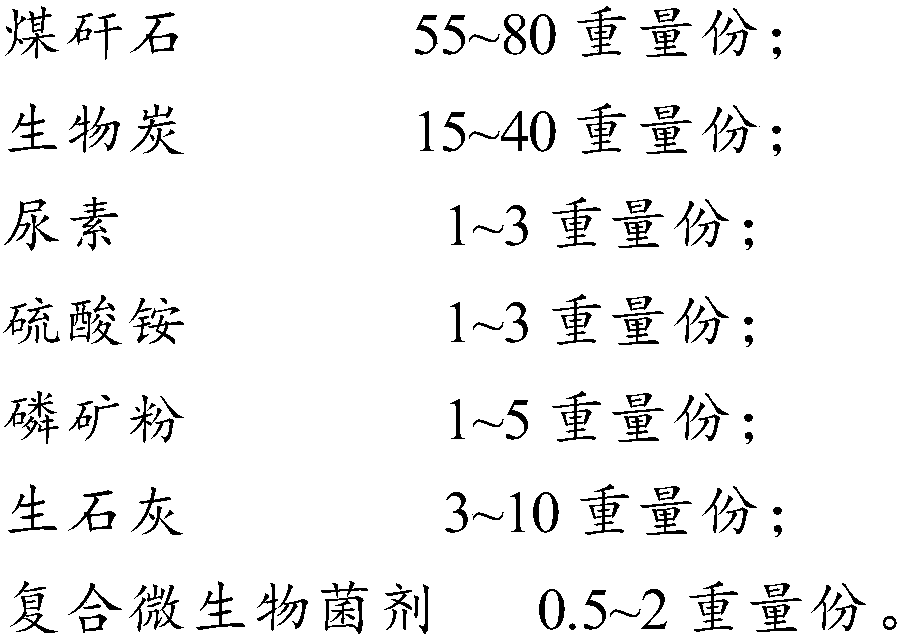

[0030] A) pulverizing coal gangue, phosphate rock powder and quicklime with biochar, urea, ammonium sulfate and compound microbial bacterial agent according to the proportion and mixing to obtain the initial mixture;

[0031] B) The initial mixture is dried and pulverized to obtain a soil conditioner.

[0032]In the process of preparing the soil conditioner, coal gangue, phosphate rock powder and quicklime are first pulverized. In this application, the biochar is preferably prepared from agricultural straw, and the agricultural straw is pulverized at the same time. The particle size of the pulverized agricultural straw is less than 20 mm, and the coal gangue, phosphate rock powder and quicklime are crushed to a particle size of less than 2 mm. After the agricultural straw is crushed, it is py...

Embodiment 1

[0040] 1) Grinding coal gangue, soybean straw, phosphate rock powder and quicklime; crushing soybean straw into particles with a particle size of 2 : 55%; Al 2 o 3 : 28%; Fe 2 o 3 : 3.6%; CaO: 2.7%; MgO: 1.5%; moisture content 24%; soybean straw includes the following components by weight: SiO 2 : 12%; Al 2 o 3 : 3%; Fe 2 o 3 : 0.7%; CaO: 28%; MgO: 9%; Na 2 O: 4%; K 2 O: 17%, moisture content 12%;

[0041] 2) Prepare biochar by pyrolyzing soybean straw for 30 minutes under nitrogen atmosphere at 500°C;

[0042] 3) 60 parts by weight of coal gangue, 30 parts by weight of biochar, 1 part by weight of urea, 1 part by weight of ammonium sulfate, 1 part by weight of phosphate rock powder, 5 parts by weight of quicklime and 1 part by weight of composite microorganisms Bacteria mix;

[0043] 4) drying the mixed material under natural conditions until the water content is 15%;

[0044] 5) Crushing, sieving (passing through a 9-mesh sieve) and subpackaging the dried materia...

Embodiment 2

[0051] 1) Grinding coal gangue, corn stalks, phosphate rock powder and quicklime; crushing corn stalks into particles with a particle size of 2 : 62%; Al 2 o 3 : 24%; Fe 2 o 3 : 4.3%; CaO: 1.6%; MgO: 0.8%; moisture content 26%; corn stalks, the weight ratio of each component is as follows: SiO 2 : 31%; Al 2 o 3 : 2%; Fe 2 o 3 : 1%; CaO: 9%; MgO: 12%; Na 2 O: 5%; K 2 O: 26%; moisture content is 10%.

[0052] 2) Prepare biochar by pyrolyzing corn stalks at 400°C under nitrogen atmosphere for 40 minutes;

[0053] 3) the coal gangue of 70 parts by weight, the biochar of 20 parts by weight, the urea of 2 parts by weight, the ammonium sulfate of 1 part by weight, the phosphate rock powder of 3 parts by weight, the unslaked lime of 3 parts by weight and the composite microorganism of 1 part by weight Bacteria mix;

[0054] 4) drying the mixed material under natural conditions until the water content is 10%;

[0055] 5) Crushing, sieving (passing through a 9-mesh sieve) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com