Oil-containing grinding sludge treatment process

A treatment process and grinding technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of large investment in fixed assets, low treatment efficiency, and high operating costs , to achieve the effect of convenient industrial production and easy operation of the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

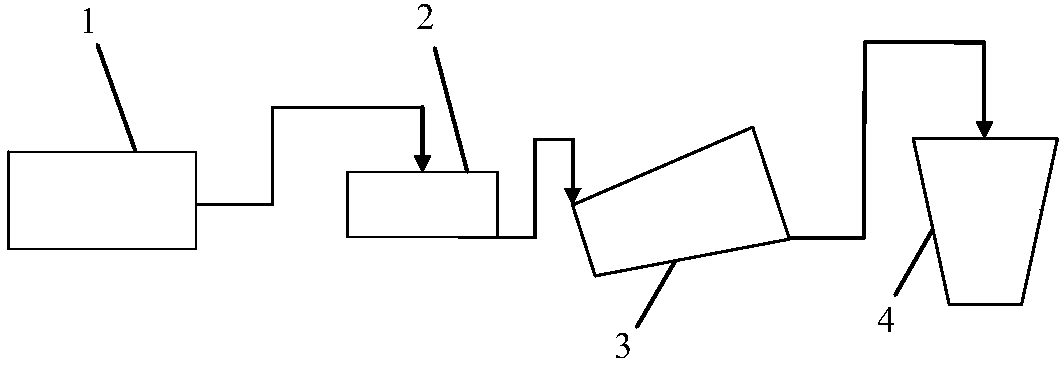

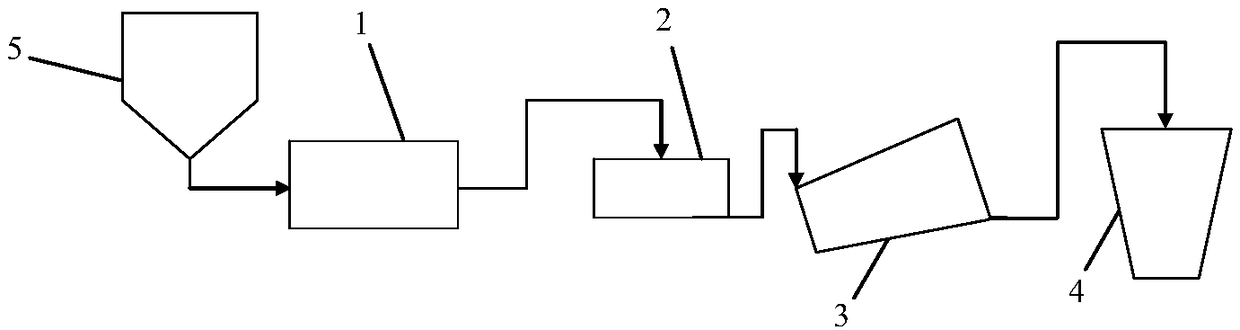

[0084] A treatment process for oil-containing grinding waste sludge, in which the oil-containing grinding waste sludge is sequentially processed through the following processes:

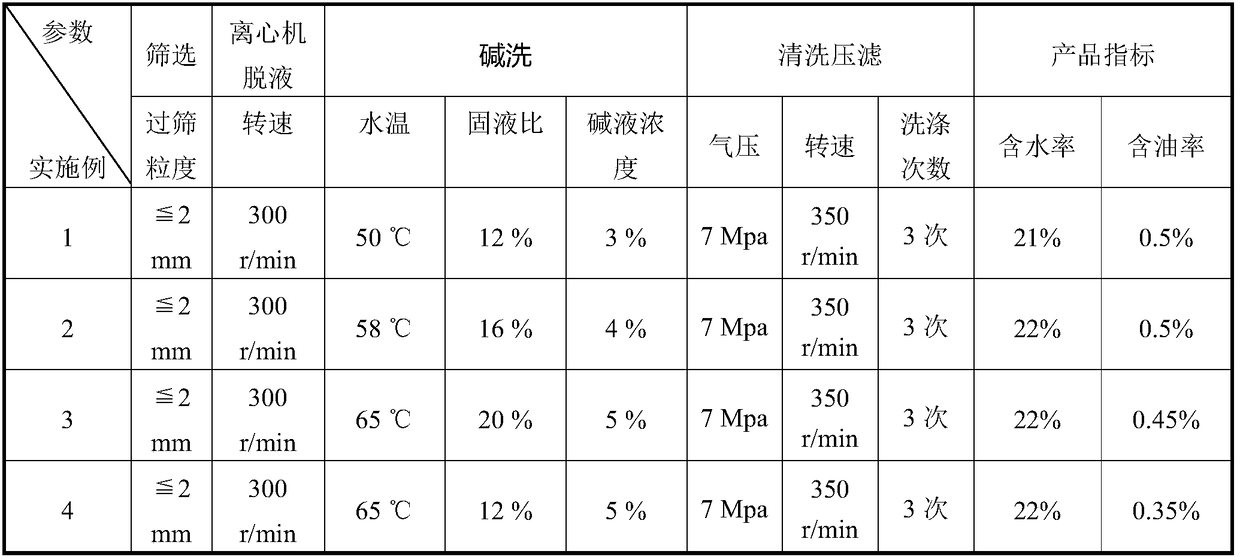

[0085] (1) Screening: add the raw material oil-containing grinding mud to the drum screening machine with a forklift for screening, and the screening particle size is ≦2mm;

[0086] (2) Centrifuge dehydration: the sieved material enters a vertical centrifuge for dehydration, solid-liquid separation, centrifuge rotation speed 300r / min, and the separated waste oil is separated and stored;

[0087] (3) Alkali washing: the solid material after deliquoring by the centrifuge enters the spiral sand washing machine, and performs alkali washing under the action of lye sodium carbonate, wherein the water temperature is 50°C, the solid-to-liquid ratio is 12%, and the lye concentration is 3%. Waste caustic soda is discharged to sewage treatment station;

[0088] (4) Cleaning and pressing filter: the oily grindi...

Embodiment 2

[0092] The difference from Example 1 is that the parameters of the alkali washing process are different, wherein the water temperature is 58° C., the solid-to-liquid ratio is 16%, and the alkali concentration is 4%.

[0093] The moisture content of the final product iron powder after the above process is 22%, and the oil content is 0.5%.

Embodiment 3

[0095] The difference from Example 1 is that the parameters of the alkali washing process are different, wherein the water temperature is 65° C., the solid-to-liquid ratio is 20%, and the alkali concentration is 5%.

[0096] The moisture content of the final product iron powder after the above process is 22%, and the oil content is 0.45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com