Airtight positive pressure operation platform

A work machine, work machine technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as injuries, and achieve the effect of effective control and avoidance of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

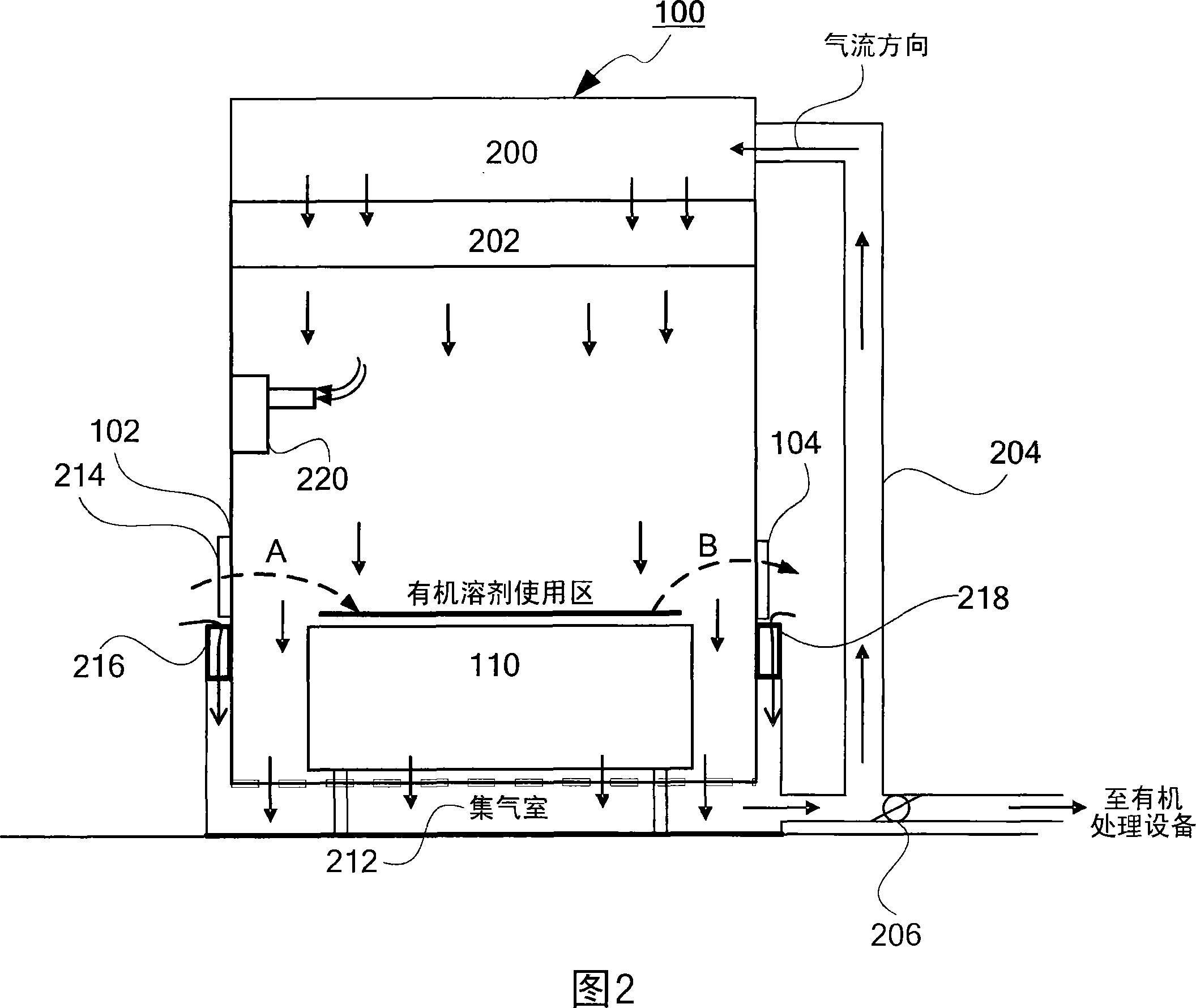

[0025] Fig. 2 is a schematic diagram of the first embodiment of the airtight positive pressure operating machine platform of the present invention. As shown in FIG. 2 , the airtight positive pressure operating machine 100 of the present invention includes an air supply chamber 200 , a fan-filter unit 202 (FFU), a workpiece transmission port 102 and a return air pipe 204 . The air supply chamber 200 is used for accommodating circulating air supplied to the inside of the airtight positive pressure working machine 100 . The fan-filter unit 202 has a fan and a filter (for example: HEPA, ULPA or components with similar functions) that drive the gas to generate flow, and are used to drive the circulating airflow of the air supply chamber 200 to be delivered to the inside of the airtight positive pressure operating machine 100 , that is, the organic solvent use area where the working platform 110 is located. The first air hood device 216 is arranged beside the workpiece conveying 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com